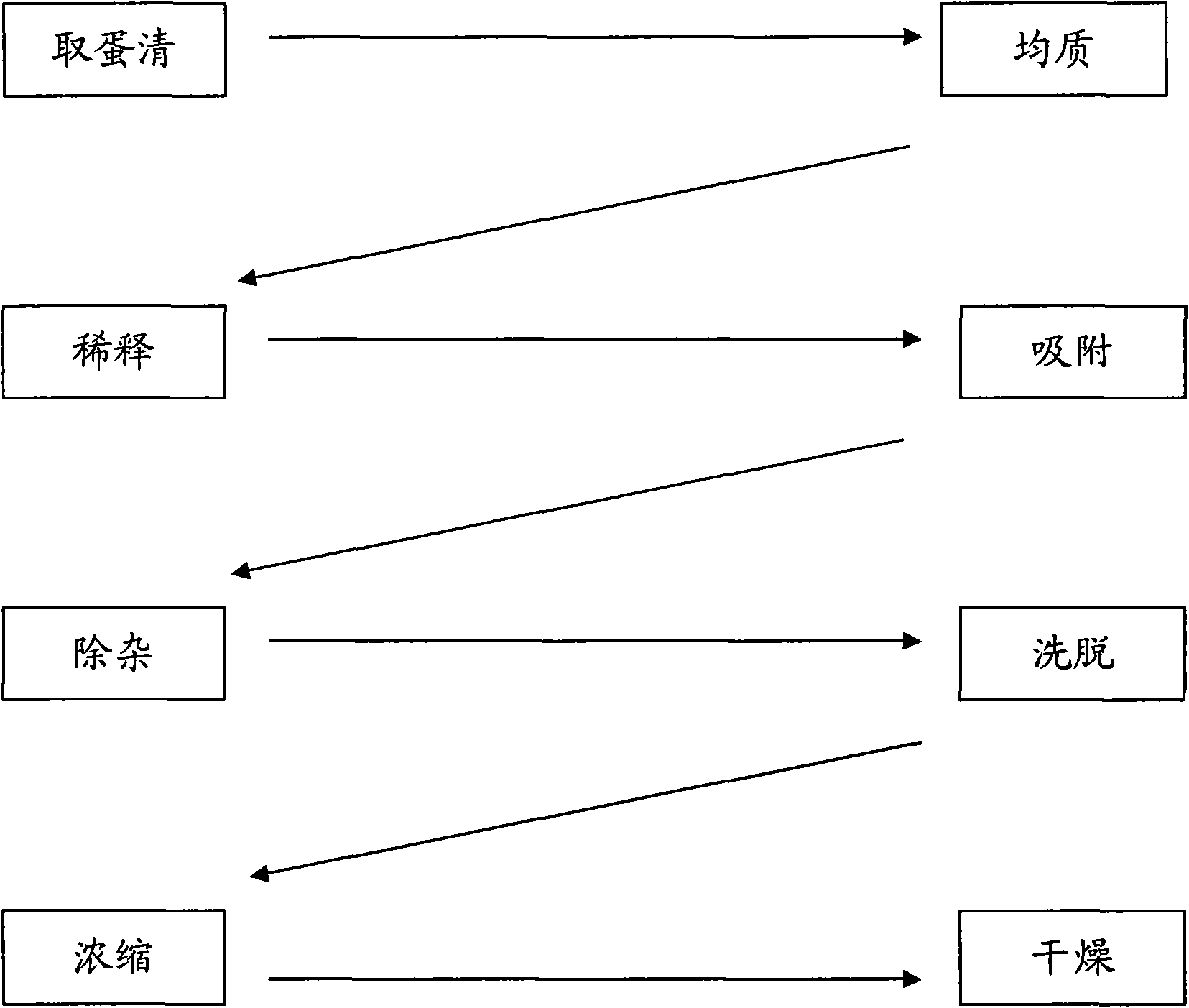

Method for extracting lysozyme from egg white

A technology of lysozyme and egg white, applied in the biological field, can solve the problems of low lysozyme efficiency and low lysozyme activity, and achieve the effects of high lysozyme activity and purity, high elution efficiency, and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 1000kg of fresh eggs, wash, sterilize and spray, and separate the egg white and egg yolk with an egg beater to obtain 600 liters of egg white.

[0031] (2) Homogenize the egg white with a homogenizer under a pressure of 3Mpa, add water accounting for 15% of the total volume of the egg white to dilute the egg white.

[0032] (3) Use a centrifugal pump to flow the diluted egg white through the Na resin in the adsorption column at a flow rate of 3 L / min.

[0033] (4) After the adsorption is completed, the Na resin in the adsorption column is backwashed with clear water to remove the remaining egg white.

[0034] (5) Then rinse the Na resin in the adsorption column with a 0.5% NaCl solution by weight to remove impurity proteins.

[0035] (6) Finally, use 600L of NaCl solution with a concentration of 2% by weight to elute the Na resin in the adsorption column with a flow rate of 4L / min, collect the eluate, and then continue to increase the concentration of the NaCl...

Embodiment 2

[0039] (1) Take 1000kg of fresh eggs, wash, sterilize and spray, and separate the egg white and egg yolk with an egg beater to obtain 600 liters of egg white.

[0040] (2) Homogenize the egg white with a homogenizer under a pressure of 6Mpa, add water accounting for 5% of the total volume of the egg white to dilute the egg white.

[0041] (3) Use a centrifugal pump to flow the diluted egg white through the Na resin in the adsorption column at a flow rate of 2L / min.

[0042] (4) After the adsorption is completed, use clean water to backwash the Na resin in the adsorption column to remove the remaining egg white.

[0043] (5) Then rinse the Na resin in the adsorption column with a 0.8% NaCl solution by weight to remove impurity proteins.

[0044] (6) Finally, 4% NaCl solution with 600L weight percent concentration is used to elute the Na resin in the adsorption column with a flow rate of 5L / min, collect the eluent, and then continue to increase the concentration of the NaCl sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com