Manufacturing method of nuclear millipore membrane

A production method and nuclear microporous membrane technology, applied in the production field of nuclear microporous membranes, can solve the problems of reduced mechanical strength, affecting production efficiency, and increasing the number of micropores, so as to facilitate high-speed production, improve production efficiency, and improve mechanical strength. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

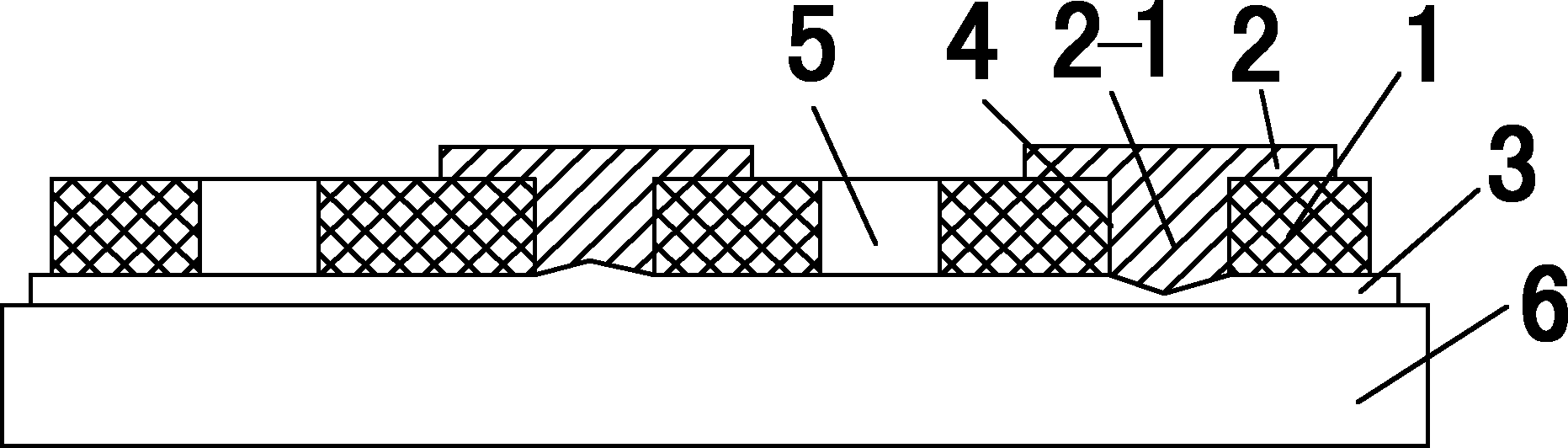

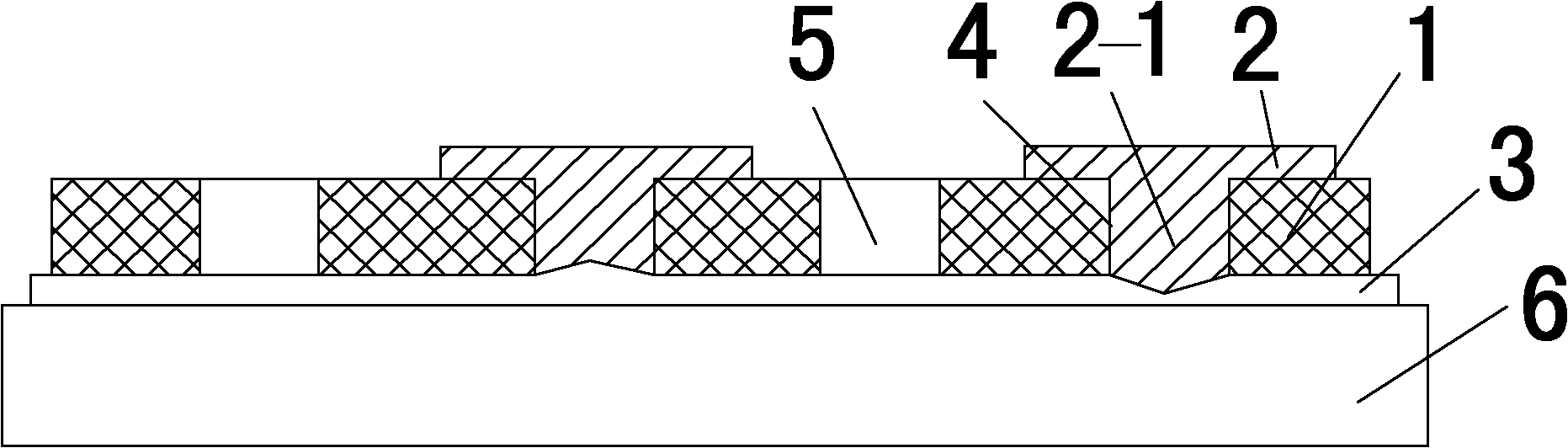

Image

Examples

Embodiment 1

[0023] A production method of a nuclear microporous membrane, comprising the steps of:

[0024] (1) Irradiation: The polymer film is irradiated, and the polymer film used is a single-layer PET film;

[0025] (2) Etching: placing the irradiated polymer film in acid solution (or lye) for double-sided full-plate etching to form micropores;

[0026] (3) Coating plugging: use varnish resin to coat the polymer film that does not need to form micropores to form a microporous membrane with complete encrypted information.

Embodiment 2

[0028] A production method of a nuclear microporous membrane, comprising the steps of:

[0029] (1) Irradiation: The polymer film is irradiated, and the polymer film used is a single-layer PET film;

[0030] (2) Composite: Composite protective film with single-layer PET film after irradiation.

[0031] (2) Etching: placing the irradiated and compounded polymer film in an acid solution (or lye) for single-sided full-plate etching to form micropores;

[0032] (3) Coating plugging: use varnish resin to coat the polymer film that does not need to form micropores to form a microporous membrane with complete encrypted information.

Embodiment 3

[0034] A production method of a nuclear microporous membrane, comprising the steps of:

[0035] (1) Irradiation: the polymer film is irradiated, and the polymer film used is a double-layer film formed by compounding one deck of PET film and one deck of protective film;

[0036] (2) Etching: placing the irradiated composite film in acid solution (or lye) for single-sided full-plate etching to form micropores on the PET film;

[0037] (3) Coating plugging: use varnish resin to coat the PET film that does not need to form microporous positions to form a microporous film with complete encrypted information.

[0038] (4) Peeling: Peel off the protective film.

[0039] The protective film in this method is made of acid and alkali etching resistant material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com