Energy-saving high-efficiency purification system for industrial volatilizable organic pollutant

An organic pollutant and energy-saving technology, which is applied in the field of energy-saving industrial volatile organic pollutant high-efficiency purification systems, can solve the problems of low purification rate of catalytic combustion bed, deactivation of catalyst, shortened service life of catalyst, etc., so as to improve self-sustained combustion. The effect of stability, improving catalytic purification rate and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

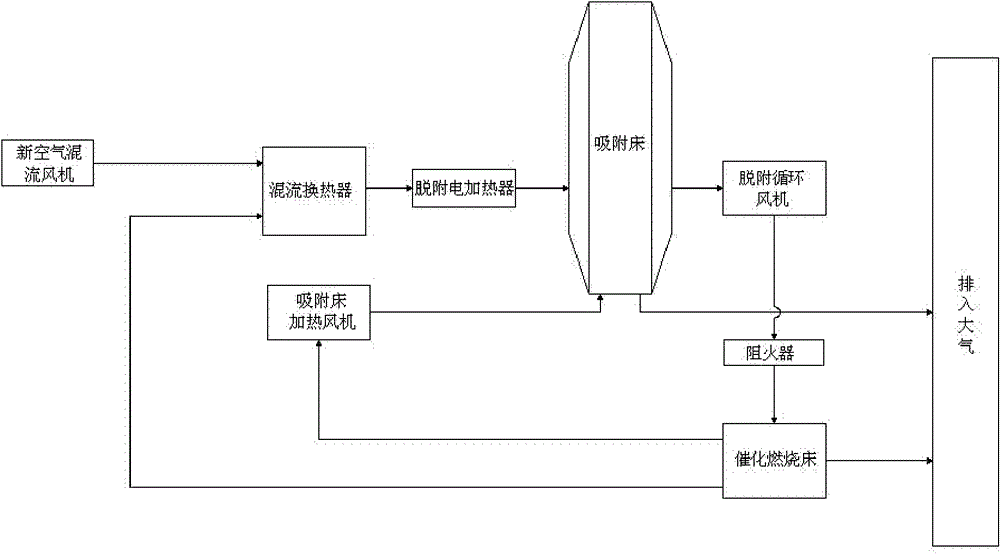

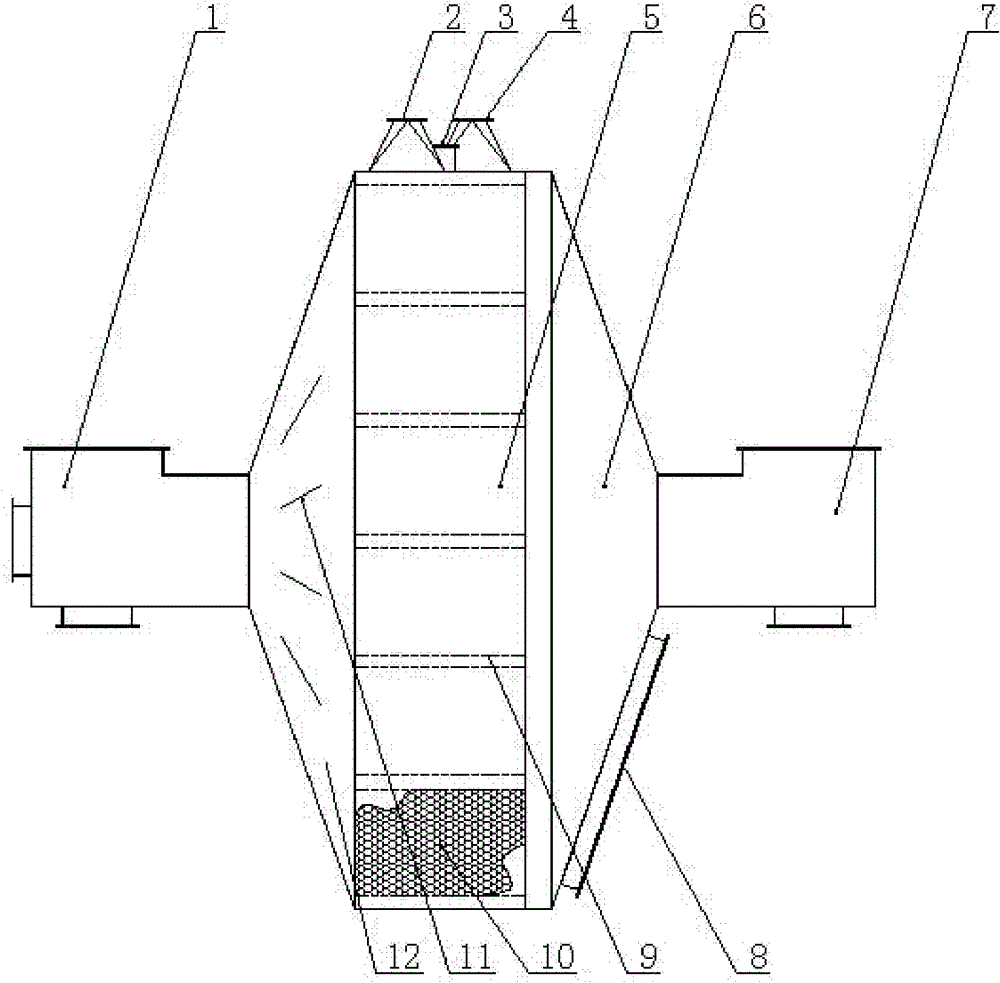

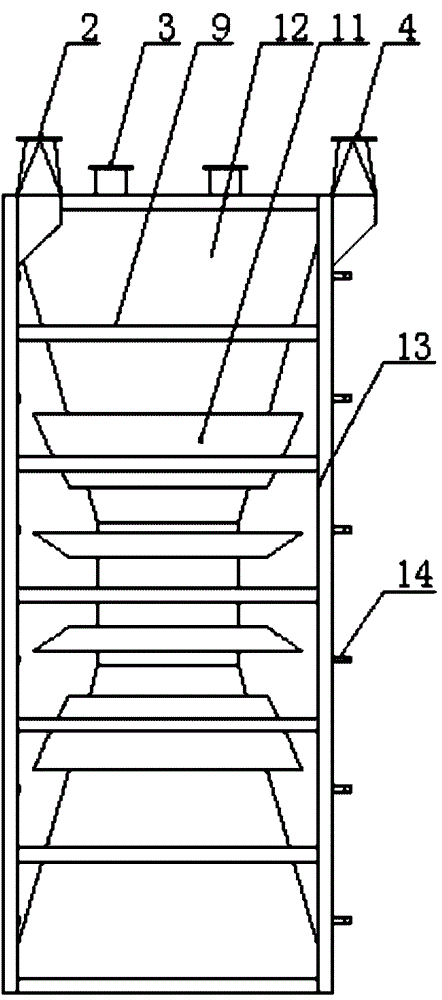

[0022] An energy-saving high-efficiency purification system for industrial volatile organic pollutants, including a mixed-flow heat exchanger, a fresh air mixed-flow fan, a catalytic combustion bed, a desorption electric heater, a desorption circulation fan, and an adsorption bed. The outlet of the fresh air mixed-flow fan passes through The pipeline is connected to the air inlet of the mixed flow heat exchanger, and the air outlet of the mixed flow heat exchanger is connected to the air inlet of the catalytic combustion bed through the desorption electric heater, adsorption bed and desorption circulation fan. The innovation points are:

[0023] (1), the catalytic combustion bed comprises a catalytic bed body 21, an air inlet 15, an air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com