Rolling bearing and rotating shaft support structure

A technology for rolling bearings and rotating shafts, applied to rolling contact bearings, roller bearings, bearings for rotational motion, etc., can solve problems such as inability to reduce noise, vibration, and damage to oil seals, and achieve good packaging and productivity , Noise reduction, good productivity and fitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

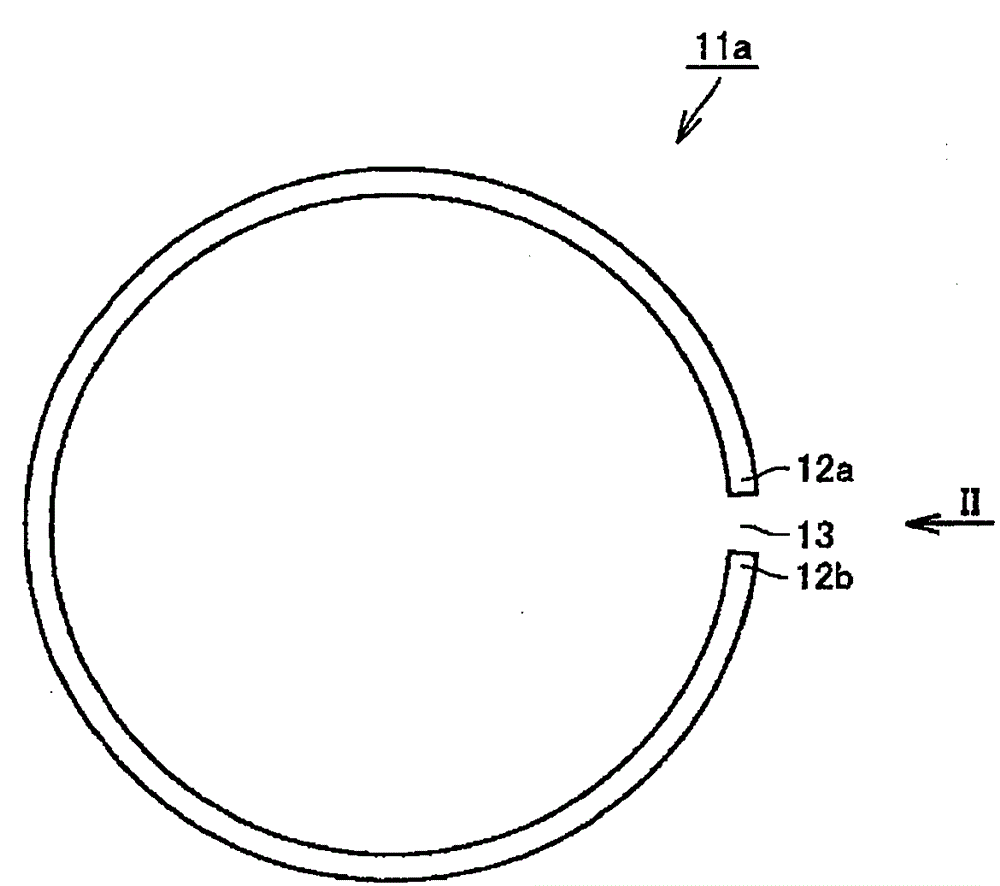

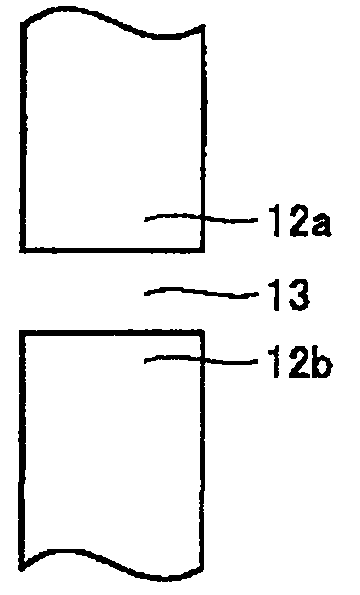

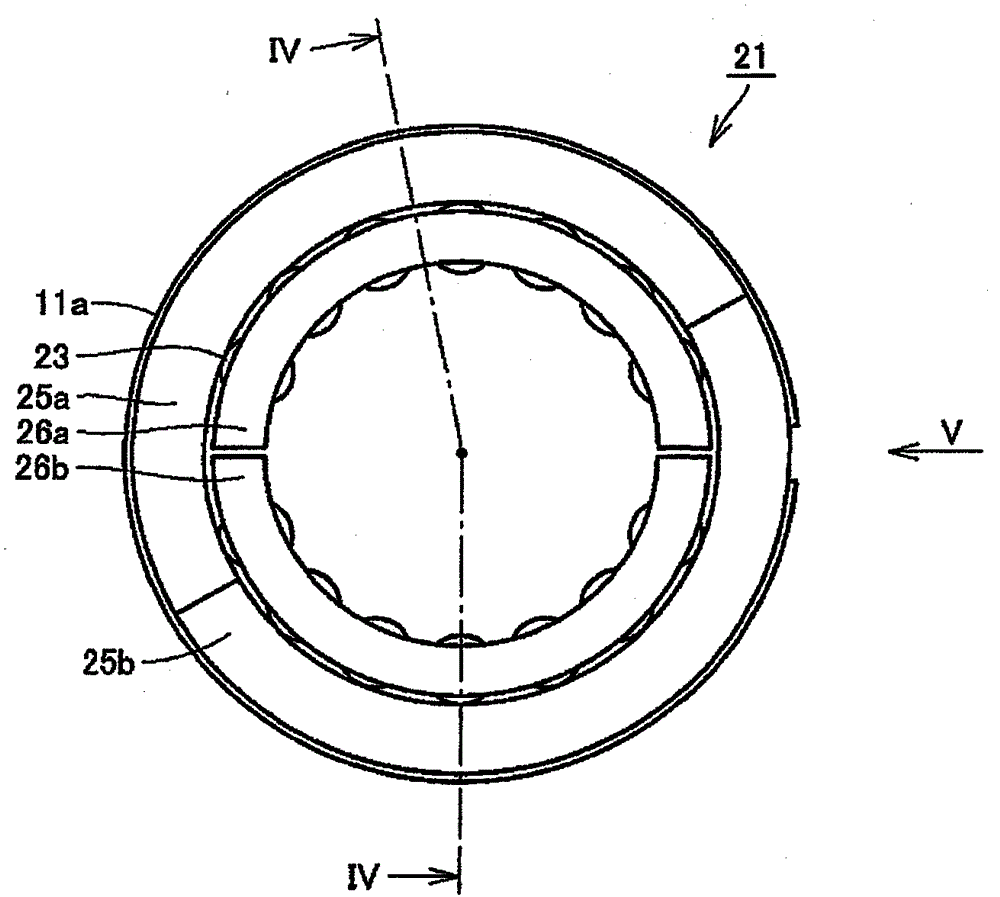

[0049] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a figure which shows the resin retaining ring with which the rolling bearing which concerns on one Embodiment of this invention is equipped. figure 2 From figure 1 Observed in the direction indicated by the arrow II in the figure 1 An enlarged view of a portion of the resin retaining ring shown. It should be noted, figure 1 This corresponds to a view viewed from the axial direction, that is, from the direction of the rotation axis of the rolling bearing when it is arranged in a rolling bearing described later.

[0050] refer to figure 1 and figure 2 The resin retaining ring 11 a is made of resin, and has a shape obtained by cutting a part of the annular member in the circumferential direction in order to form the gap 13 . That is, the resin retaining ring 11a has two end portions 12a, 12b opposed in the circumferential direction, and has a stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com