Drive control method and system for large-caliber telescope arc motor

A large-diameter, telescope technology, applied in the control system, vector control system, motor generator control and other directions, can solve the problems of long development cycle and high development cost, achieve simple circuit, strong practicability, and high-precision tracking of celestial bodies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

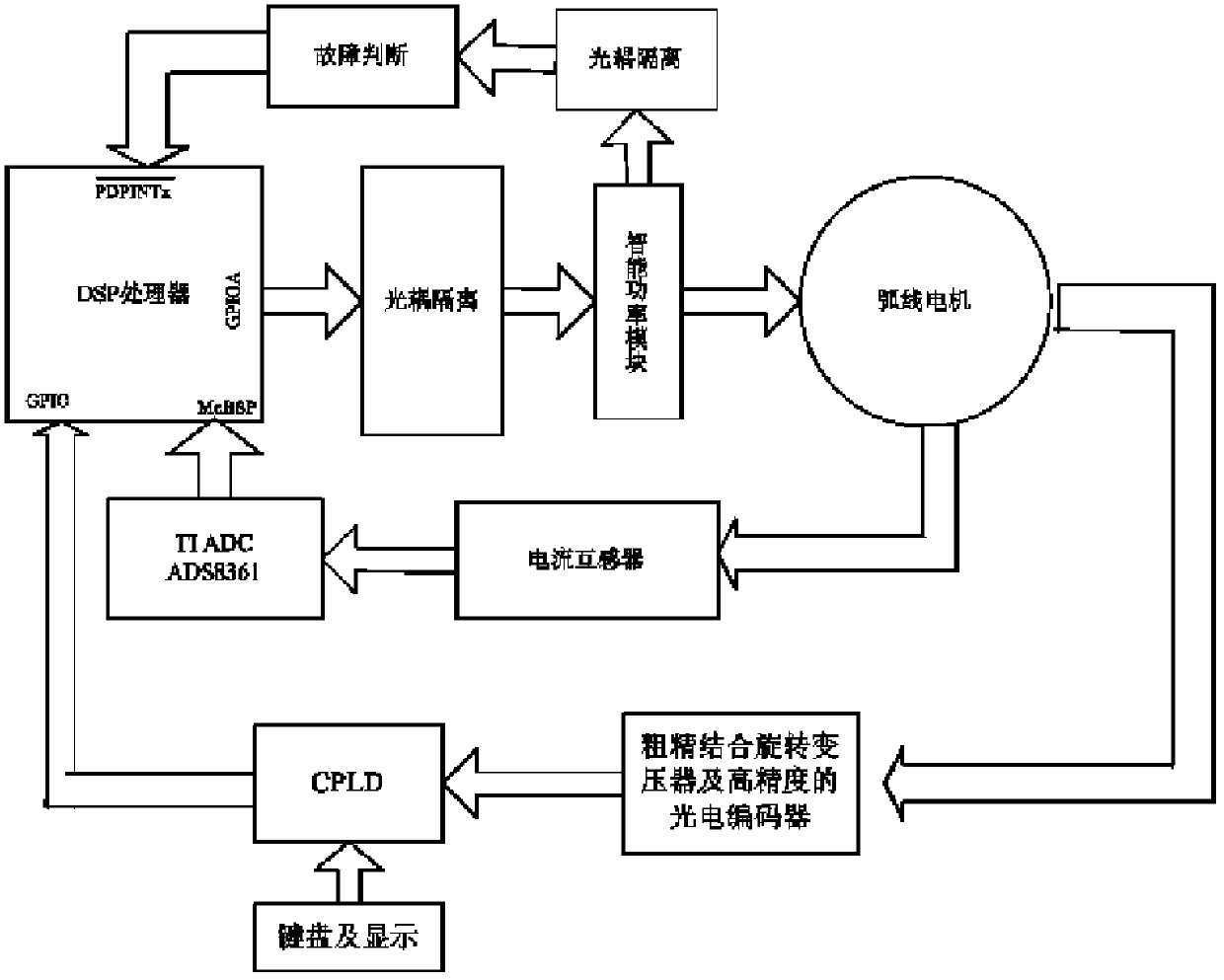

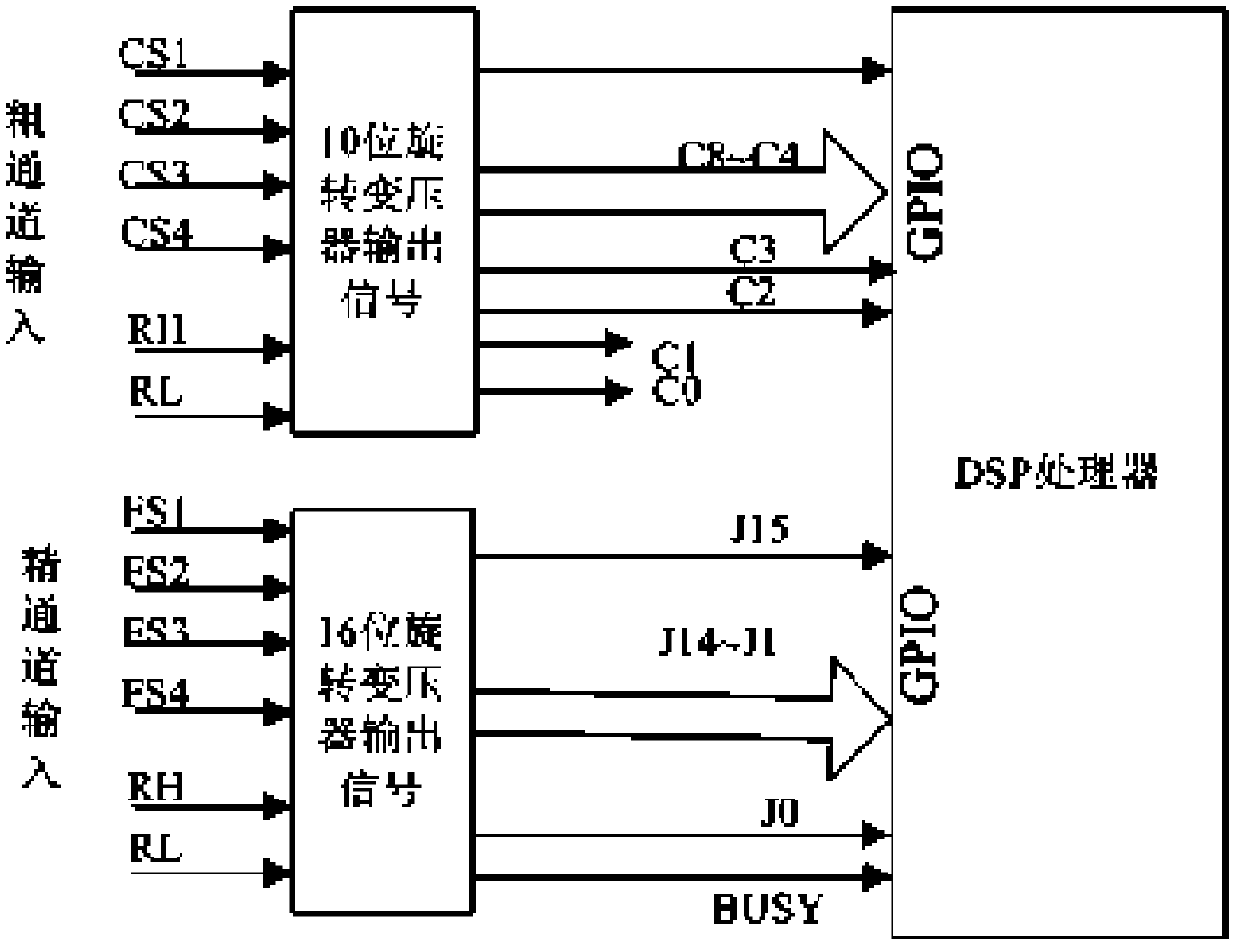

[0053] Embodiment 1, large-diameter millimeter wave / submillimeter wave telescope arc motor drive control system, the arc motor is a self-developed multi-pole AC permanent magnet synchronous arc motor, which is a unit combination type. The present invention is to design the arc motor The drive control system of the line motor requires wide speed regulation, ultra-low speed, and no crawling phenomenon at low speed. The drive control system is composed of DSP processor and digital intelligent power module, mainly composed of the following parts.

[0054] 1. Frequency conversion inverter

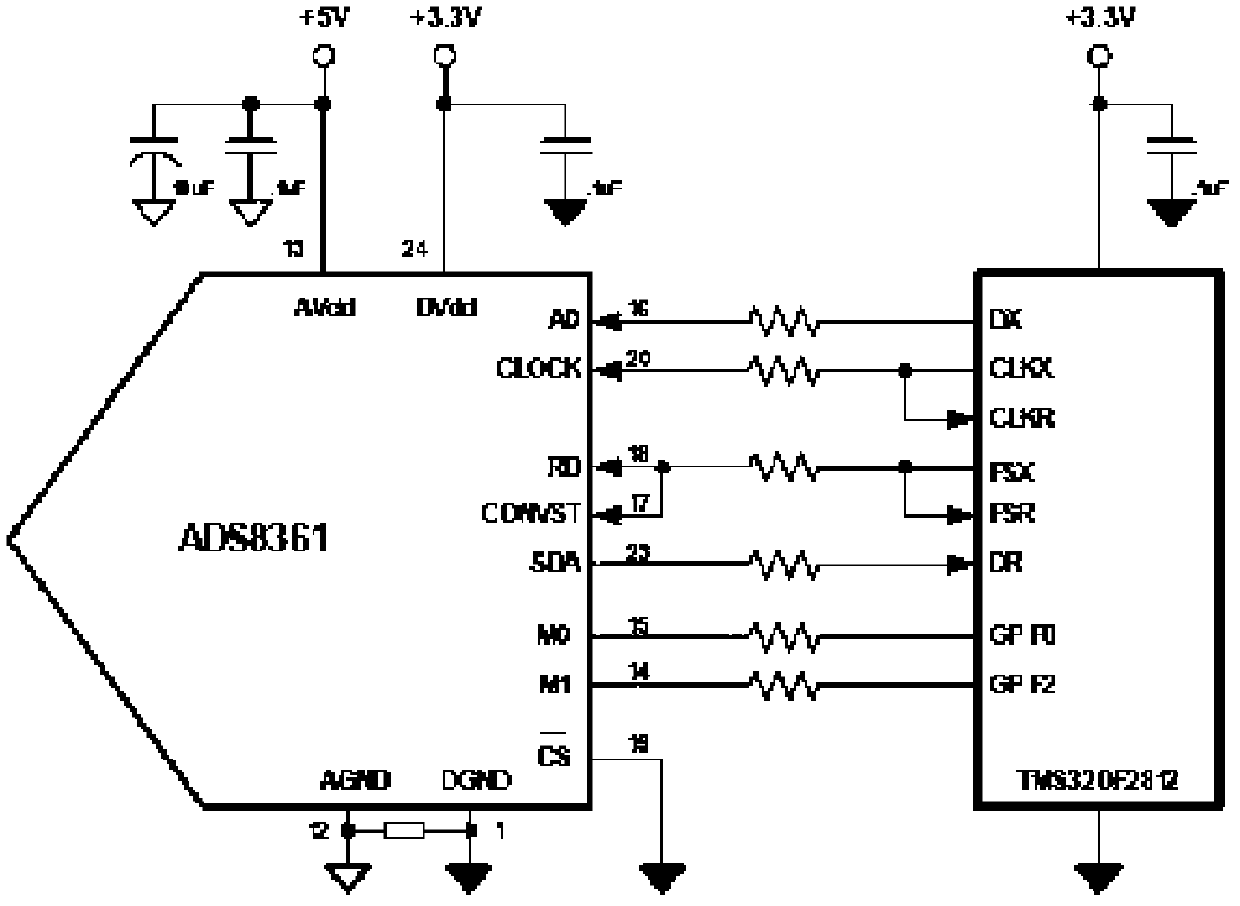

[0055] The intelligent power module used in the frequency conversion and inverter part is PMS25RLA120, which can withstand high voltage up to 1200V and has a fault output terminal; the event manager A or B of TMS320F2812 uses the space voltage vector algorithm to manage events in TMS320F2812 according to the adjustment algorithm of the controller. Under the action of the timer of the inverter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com