Construction method for replacing cross arm of 35kV line linear rod

A construction method and straight rod technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor intensity of operators, affecting the normal operation of the crossed transmission line, and long construction time, so as to achieve simple and feasible construction methods and improve safety performance and reliability, and the effect of ensuring the quality of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

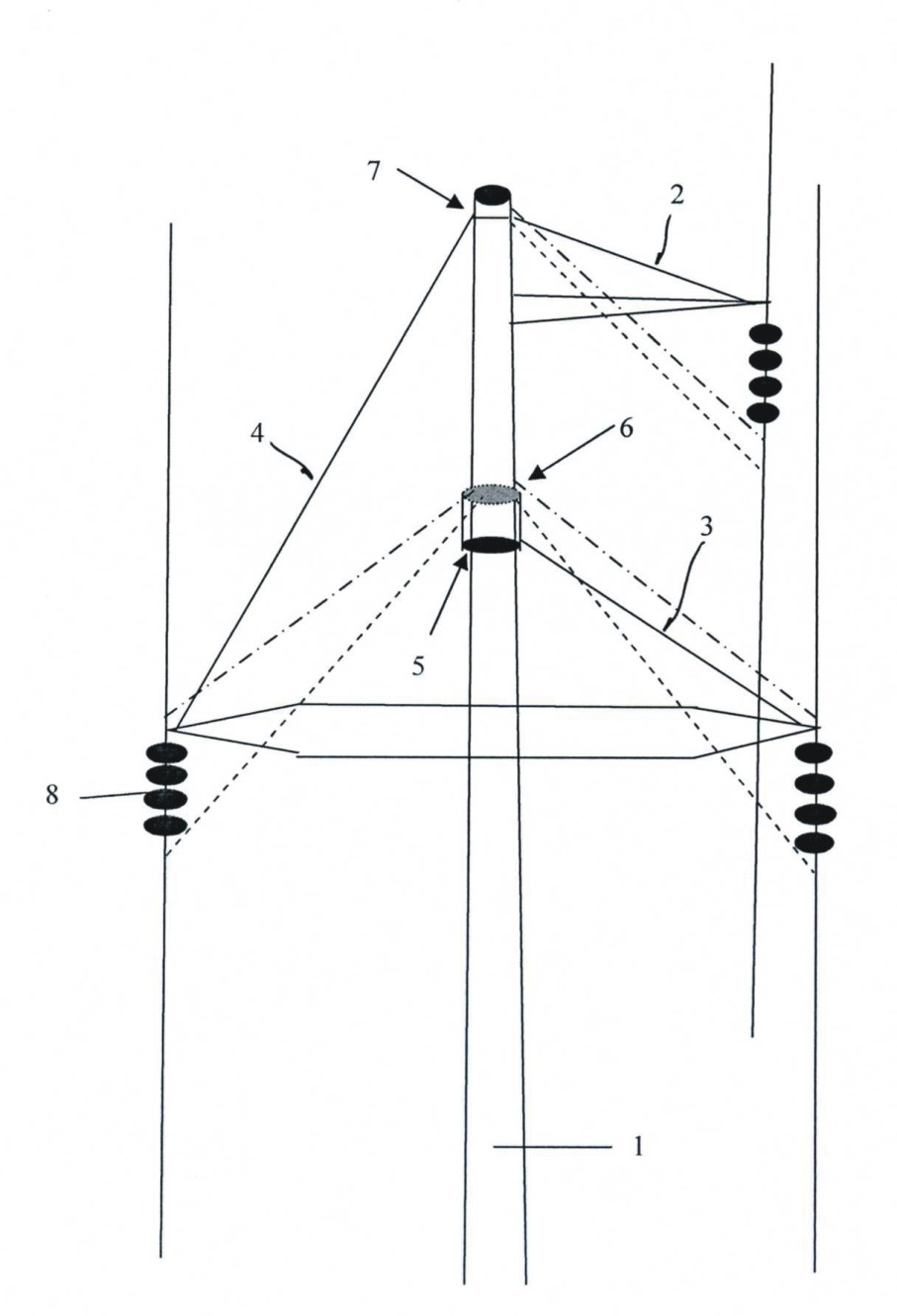

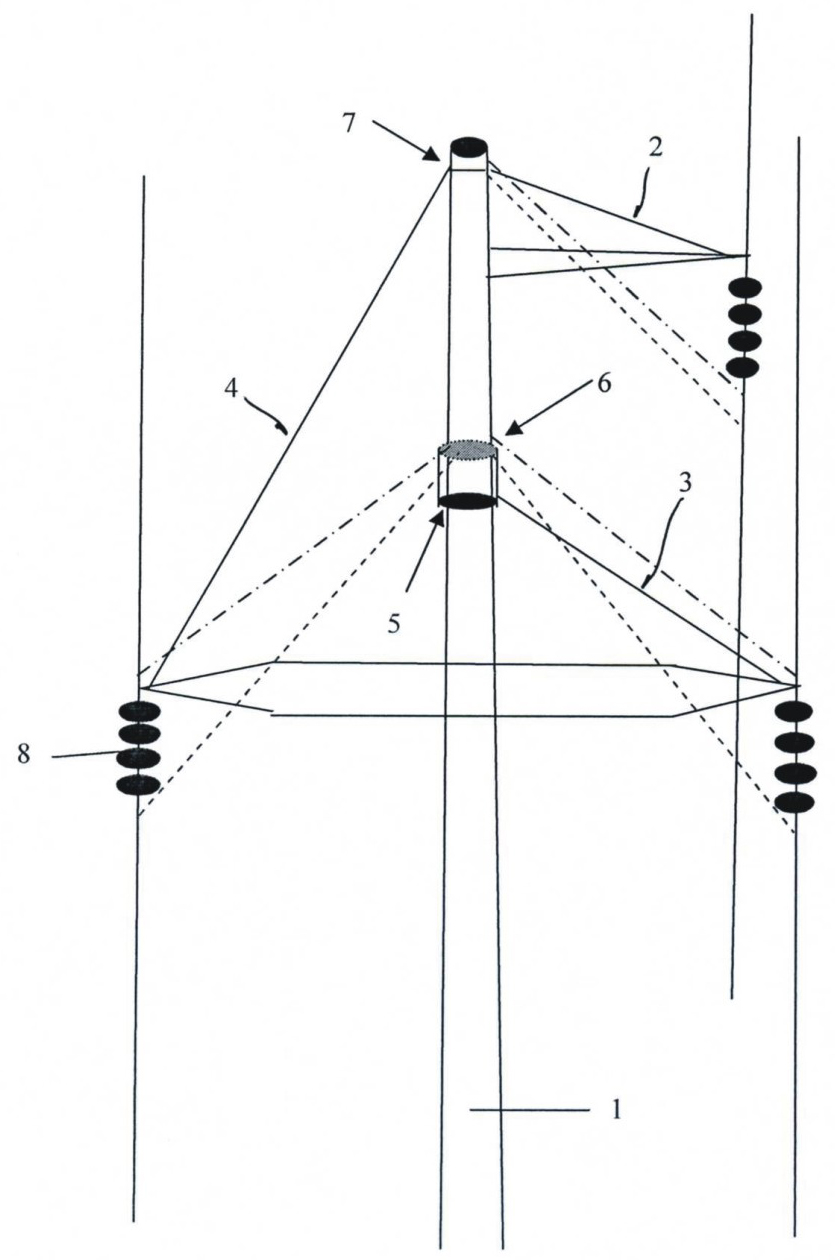

[0017] Replacement Straight Rod Cross Arm with Tension:

[0018] Construction principle: to successfully transfer the hanging point of the three-phase wire to the pole, so that the old cross-arm is completely emptied and replaced with a new cross-arm. It is the key of the present invention to keep the balance of force on the shaft all the time in the transfer process.

[0019] Construction points: in the process of work must meet:

[0020] 1. The wire must not lose the "secondary protection" of the wire sleeve on the wire at any time;

[0021] 2. Special personnel must be arranged to monitor the force of the pole at any time and the safe distance of crossing the power line under the line.

[0022] Tool preparation:

[0023] 1. 3 2T ratchet-type wire tensioners (used for lifting wires);

[0024] 2. Three φ14×1m steel wire sleeves (three 2T ratchet-type wire tensioners are hung on the shaft for use);

[0025] 3. 1 piece of φ12×2m steel wire sleeve (used for "secondary prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com