A processing method of inefficient solar cell sheets

A technology of solar cells and processing methods, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of small fill factor FF of series resistance Rs and reduce conversion efficiency, etc., to reduce series resistance Rs and reduce contact Resistance, the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Based on the above reasons, an embodiment of the present invention provides a method for processing low-efficiency solar cells. The flow chart of the method is as follows figure 1 shown, including the following steps:

[0039] Step S101: Screen low-efficiency solar cells from the finished solar cells. Generally, the low-efficiency solar cells are cells with a conversion efficiency lower than 16%. The factor is too small, which leads to low conversion efficiency;

[0040] Step S102: Put the selected low-efficiency solar cells into an annealing furnace for hydrogen annealing.

[0041] Those skilled in the art can understand that the series resistance Rs of the cell is too large, the parallel resistance Rsh is too small, the fill factor FF is too small, etc., all of which can lead to low efficiency of the solar cell. Therefore, to improve the conversion efficiency of the solar cell , can start from reducing the series resistance, increasing the parallel resistance and fi...

Embodiment 2

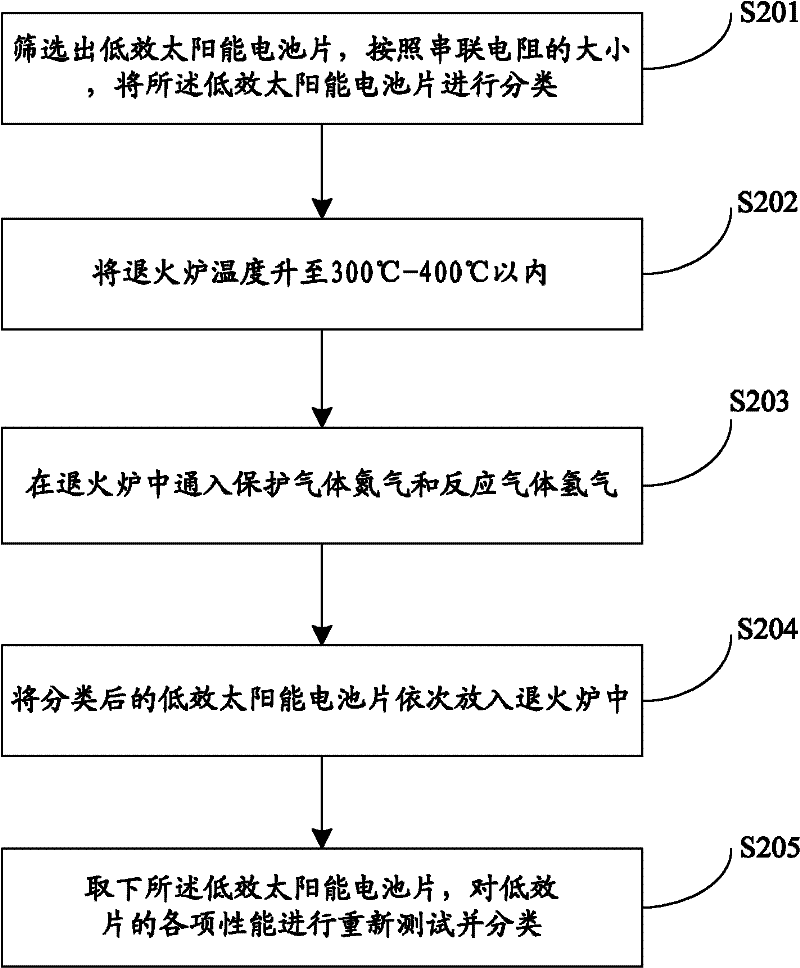

[0049] The flow chart of the method for processing low-efficiency solar cells disclosed in this embodiment is as follows: figure 2 As shown, this embodiment is more specific than the previous embodiment, including the following steps:

[0050] Step S201: Screen out the low-efficiency solar cells, and classify the low-efficiency solar cells according to the size of the series resistance, so as to make statistics on the influence of the hydrogen annealing process on the performance of the low-efficiency solar cells, and to facilitate the classification after annealing process to improve production efficiency;

[0051] Step S202: raising the temperature of the annealing furnace to within 300°C-400°C;

[0052] Step S203: feeding protective gas nitrogen and reaction gas hydrogen into the annealing furnace, wherein the speed of feeding nitrogen is within 30L / min-50L / min, and the speed of feeding hydrogen is within 3L / min-10L / min;

[0053] Step S204: Put the sorted low-efficiency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Series resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com