Modeling method for combustion optimization of porous medium combustor

A technology of porous media and combustion optimization, applied in the field of information control, can solve problems such as time-consuming, labor-intensive effects, and limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

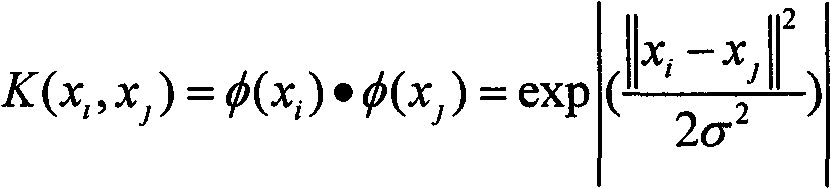

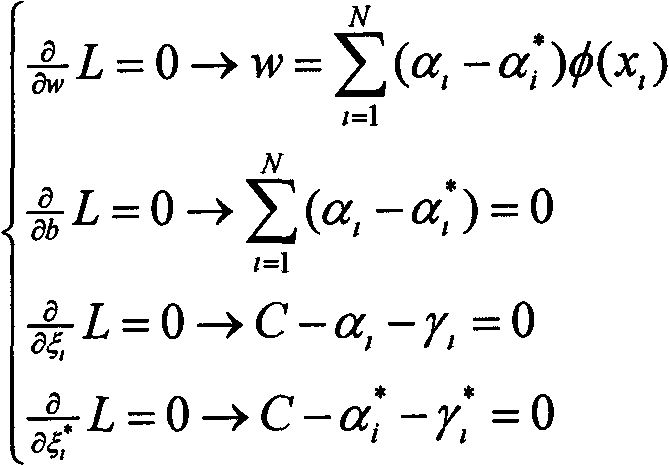

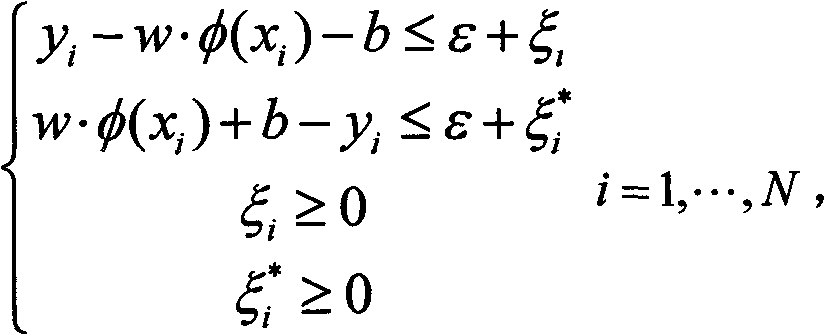

Method used

Image

Examples

Embodiment Construction

[0045] A modeling method for combustion optimization of a porous media burner, the specific steps are:

[0046] (1) Collect the operating parameters of the porous media burner and related characteristic indicators representing the combustion state of the porous media burner, and establish a real-time database; the specific operating parameters of the porous media burner are obtained through the real-time operation database of the porous media burner, or directly through the instrument Device measurement collection.

[0047] The operating parameter data of the porous media burner includes primary wind speed, secondary wind speed, oxygen content, gas speed and gas industry analysis index; the data of the characteristic index representing the combustion state of the porous media burner includes NO Concentration and combustion efficiency of porous media burners, the method of obtaining it is a mature technology.

[0048] Step (2) Select and preprocess the data in the database, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com