Method for quickly detecting crosslinked polyethylene cable insulating material structure

A technology for cross-linked polyethylene and cable insulation, which is applied in the direction of applying stable tension/pressure to test material strength, analyze materials, and measurement devices. It can solve problems such as indirect characterization methods, poor repeatability, and long experiment cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Put 96.7g of polyethylene PE1030, 0.3g of glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate and 3.0g of dicumyl peroxide in the internal mixer , at a temperature of 110° C., 30 rpm, blended for 6 minutes, and discharged to obtain a premixed material. 10 g of the premixed material was cross-linked in a vulcanizer at a temperature of 175° C. for 10 minutes to obtain cross-linked polyethylene.

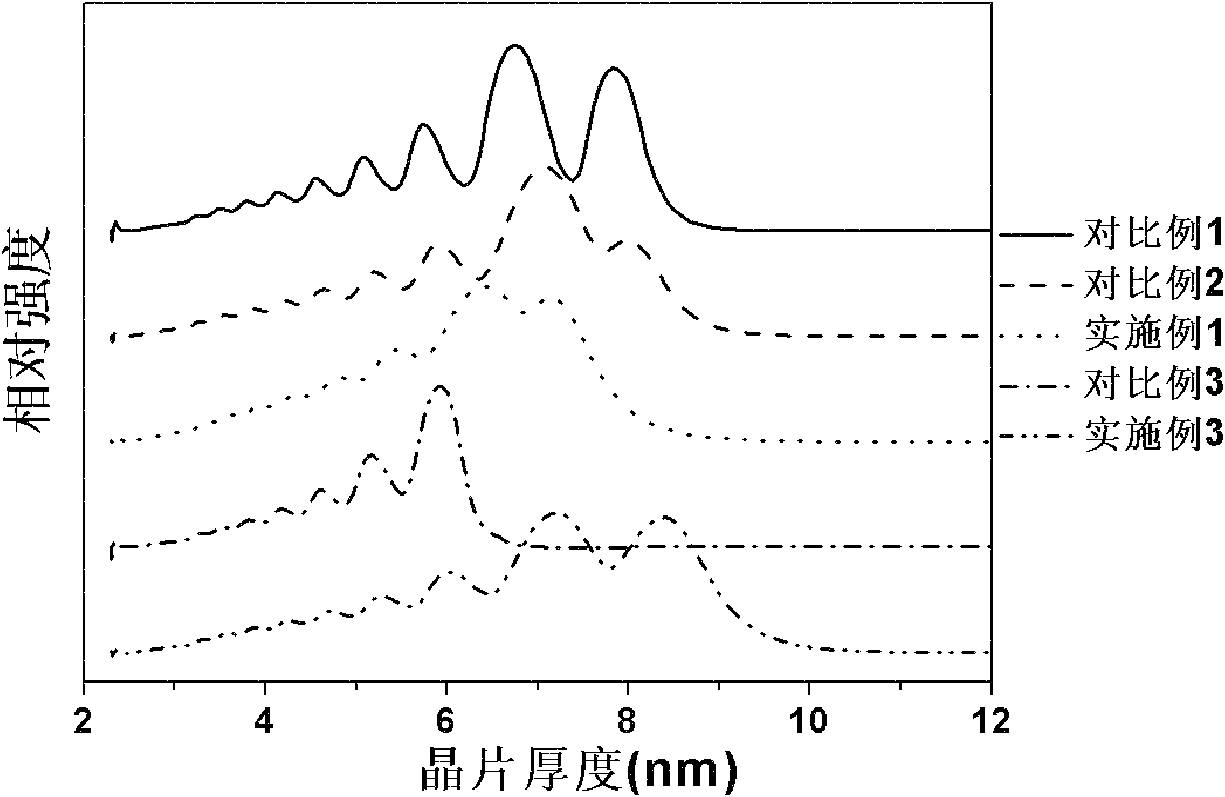

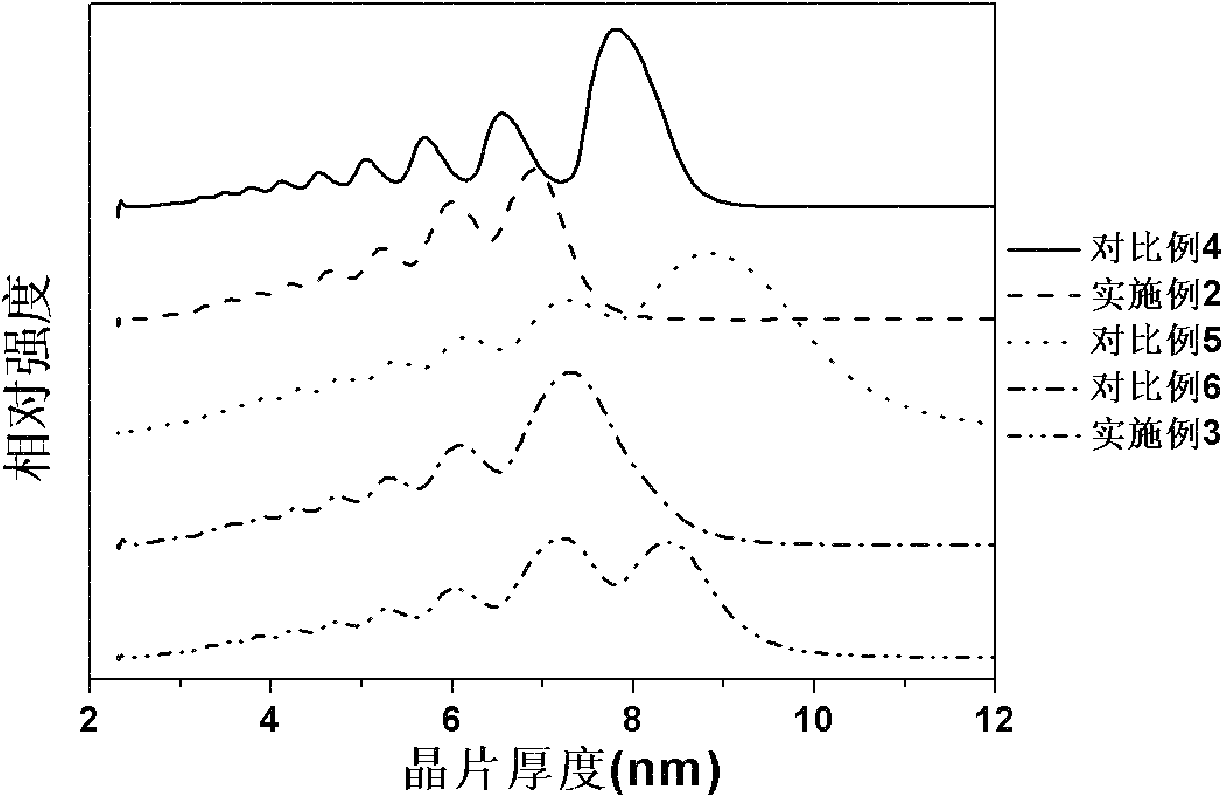

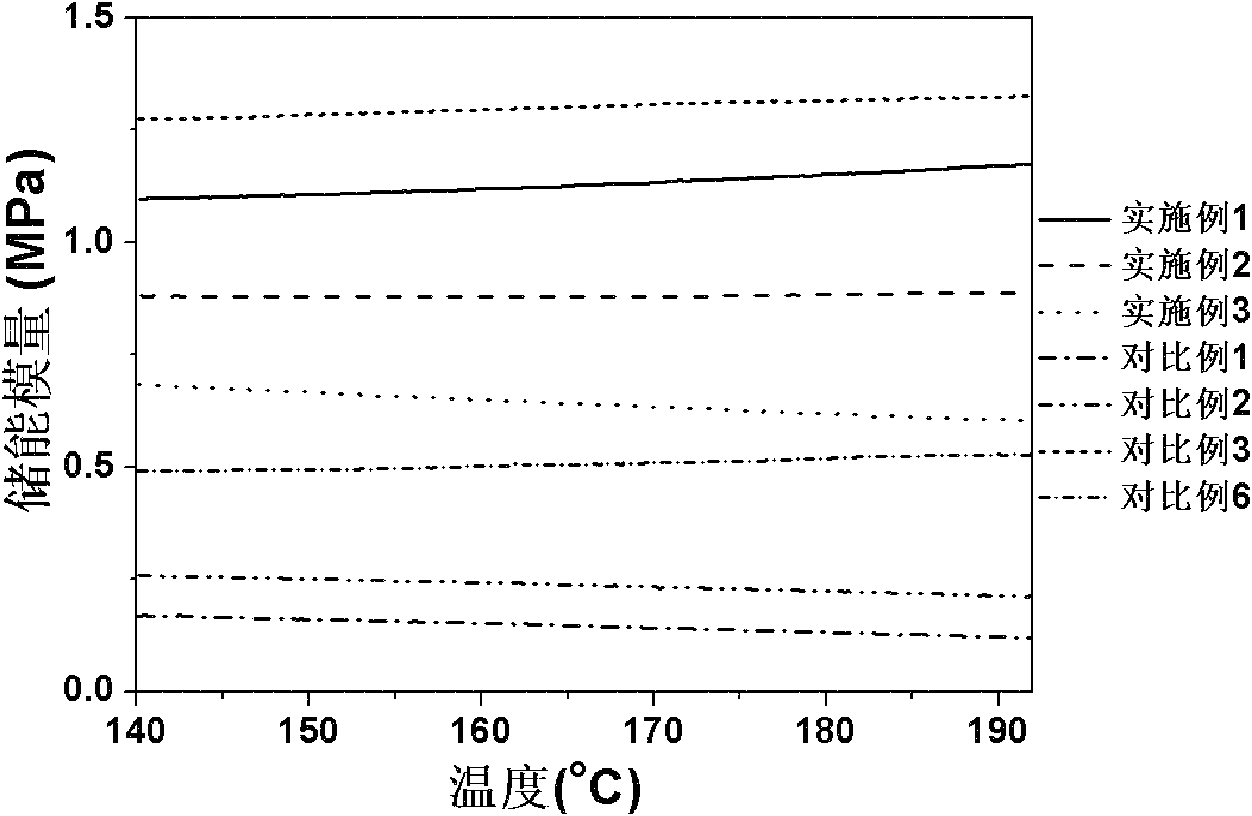

[0058] The above-mentioned cross-linked polyethylene is subjected to thermal classification analysis, and the results of the thermal classification experiment are further calculated with Thomson-Gibbs equation (1) and statistical formulas (2)-(4), and the wafer thickness distribution curve and number average of the sample are obtained. Wafer thickness L n , Weight average wafer thickness L w , Wafer distribution coefficient I, the results are shown in Tables 1 to 4 and Figure 1.

[0059] L = 2 σ ...

Embodiment 2

[0074] Put 97.8g of polyethylene PE1030, 0.2g of 2,6-di-tert-butyl-4-ethylphenol and 2.0g of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane into the internal mixer , at 118° C., 50 rpm, blended for 9 minutes, and discharged to obtain a premixed material. 10 g of the premixed material was cross-linked in a vulcanizer at 170° C. for 15 minutes to obtain cross-linked polyethylene.

[0075] The above-mentioned cross-linked polyethylene was subjected to thermal classification analysis, and the Thomson-Gibbs equation (1) and statistical formulas (2)-(4) were used to further calculate the results of the thermal classification experiment to obtain the wafer thickness distribution curve and the number average of the samples. Wafer thickness L n , Weight average wafer thickness L w , Wafer distribution coefficient I, the results are shown in Tables 1 to 4 and Figure 1.

[0076] L = 2 σ Δ ...

Embodiment 3

[0091] Put 100.0 g of polyethylene PED4 in an internal mixer, blend at 115° C., 40 rpm, and discharge for 7 minutes to obtain a premixed material. 10 g of the premixed material was cross-linked in a vulcanizer at 175° C. for 10 minutes to obtain cross-linked polyethylene.

[0092] The above-mentioned cross-linked polyethylene was subjected to thermal classification analysis, and the Thomson-Gibbs equation (1) and statistical formulas (2)-(4) were used to further calculate the results of the thermal classification experiment to obtain the wafer thickness distribution curve and the number average of the samples. Wafer thickness L n , Weight average wafer thickness L w , Wafer distribution coefficient I.

[0093] L = 2 σ Δ H 0 * T m 0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface free energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com