Rapid electric auxiliary heating device for solar water heater

A technology for solar water heaters and heating devices, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of prolonged electric heating time, unfavorable safety, accelerated water storage and heat dissipation, etc., and achieves improved performance, heat collection Good effect, high hot water output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

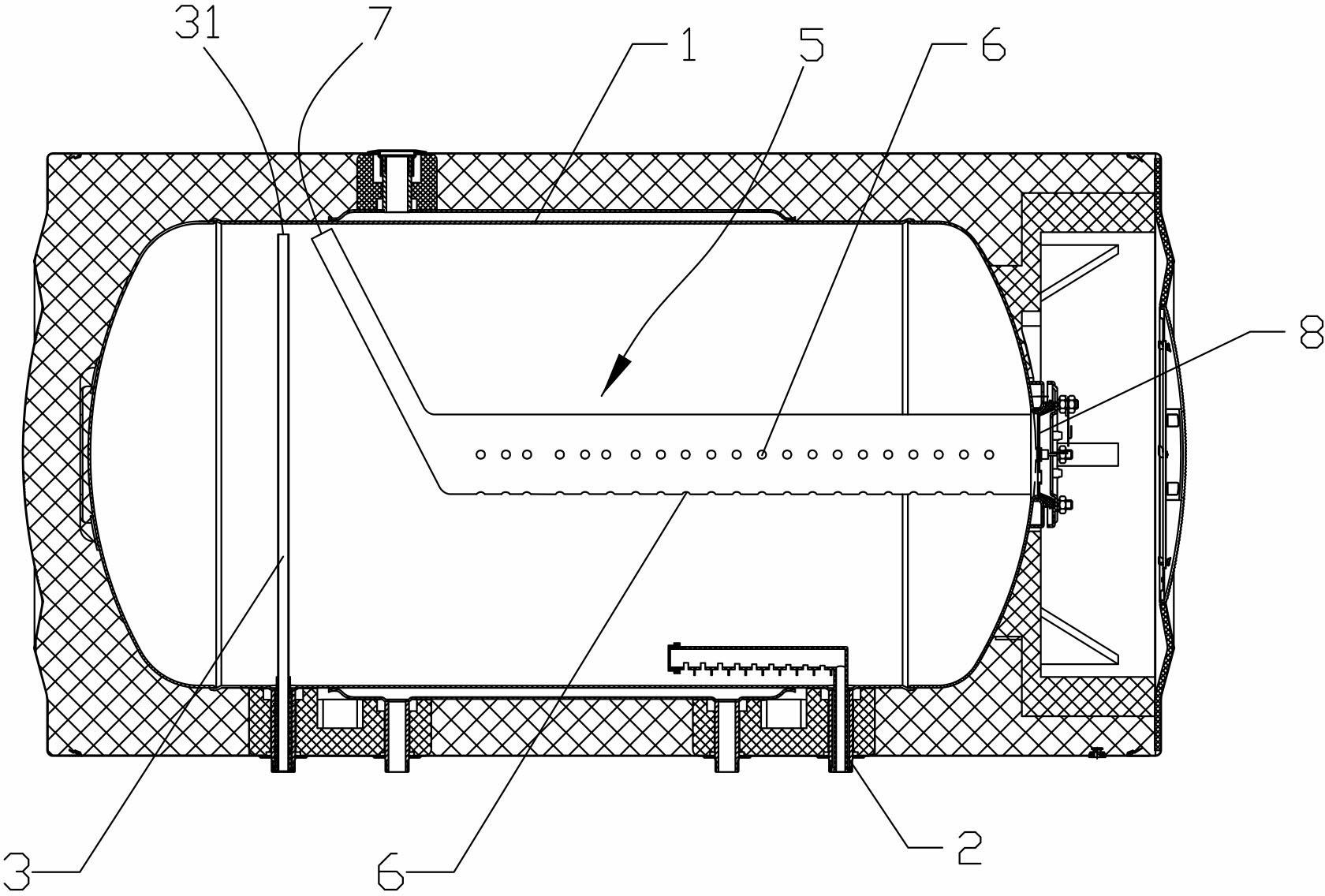

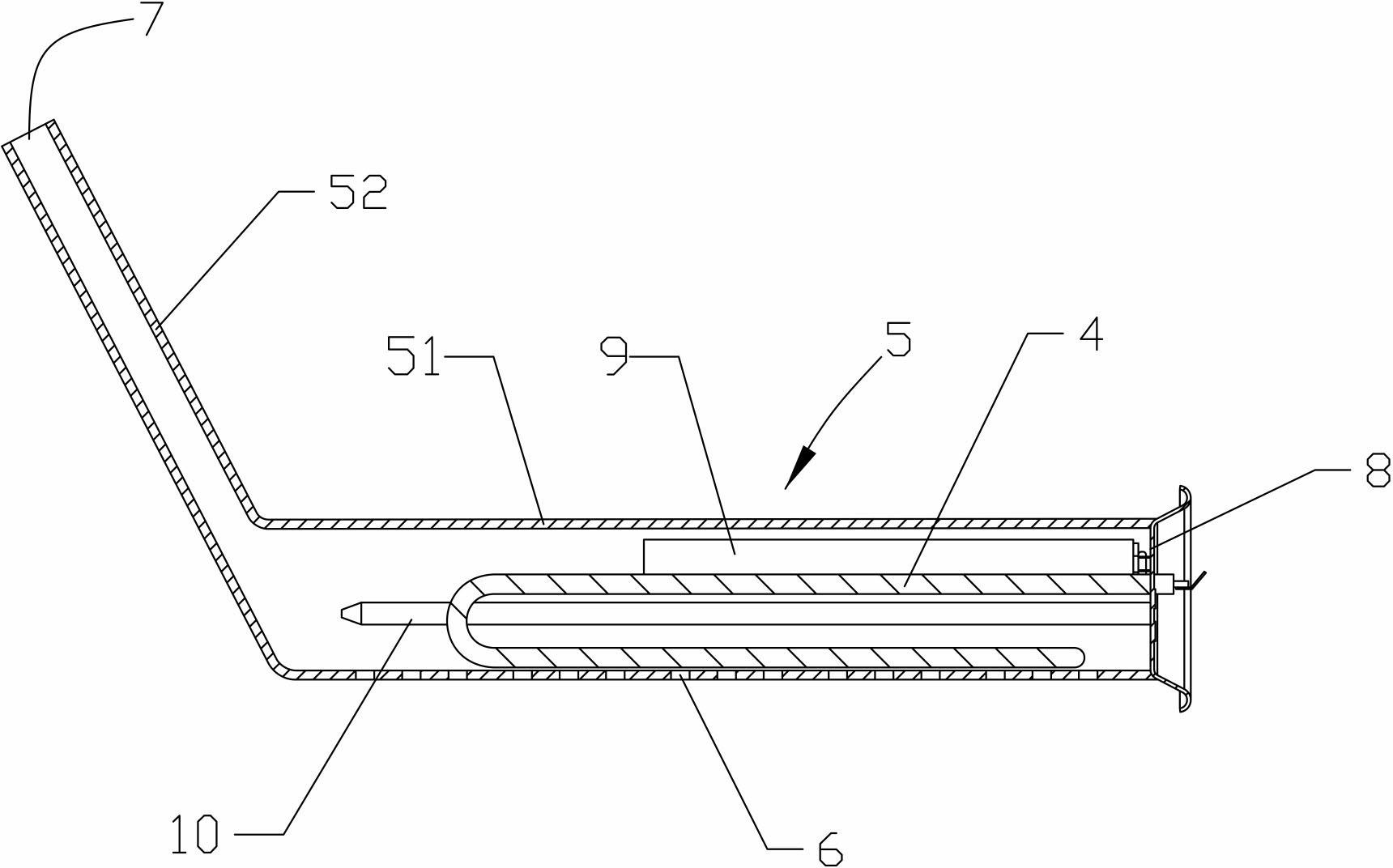

[0022] according to Figure 1 to Figure 3 As shown, it is the best embodiment of the present invention, the solar water heater of the present invention uses fast electric auxiliary heating device, and it is applied to the cold water heating of electric water heater or solar water heater. The present invention includes an inner container 1 of the water heater and a water inlet pipe 2 and an outlet pipe 3 connected to the inner cavity of the inner container 1. The inner container 1 is generally made of steel and has a horizontal structure, and the water inlet pipe 2 passes through the bottom of the inner container 1. Into the bottom of the inner cavity of the inner tank 1 to supply cold water to the inner tank 1, while the outlet pipe 3 passes out from the top of the inner cavity of the inner tank 1 to the outside of the inner tank 1. Since hot water is less dense than cold water and floats up, Therefore, the water inlet port 31 of the water outlet pipe 3 is generally located at...

Embodiment 2

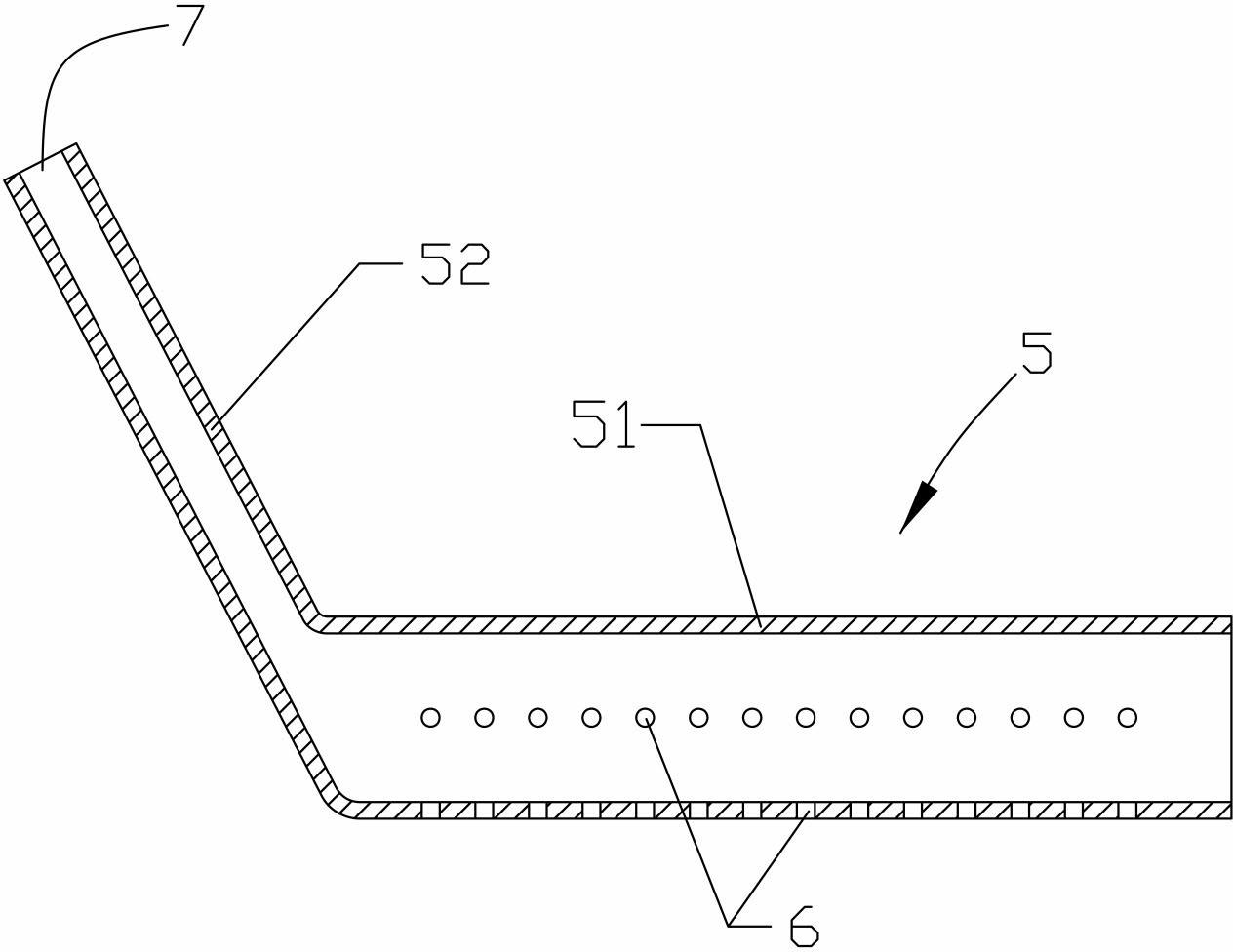

[0027] see Figure 4 , this embodiment is another embodiment of the present invention, the structure of this embodiment is basically the same as the structure of the above-mentioned preferred embodiment, the slight difference is that: the heat collecting and guiding tube 5 can also be a straight tube structure, it is set Outside the electric heating tube 4, it extends straight to the side of the water inlet port 31 of the water outlet pipe 3, and it can extend obliquely upward from the central position of the electric heating tube base 8 to the side of the water inlet port 31 of the water outlet pipe 3. The mode is more in line with the natural floating characteristics of hot water. After being heated, the water can naturally go upward along the heat collecting and guiding tube immediately, so that the hot water in the heat collecting and guiding tube 5 can be quickly guided to the inlet of the outlet pipe 3. Water port 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com