High heat dissipation LED lamp light source

A technology of LED lamp and high heat dissipation, applied in the field of high heat dissipation LED lamp light source, can solve the problems of inconvenient recycling, complicated processing technology, heavy weight of the whole lamp, etc., and achieve the effect of convenient processing, lower sales price and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

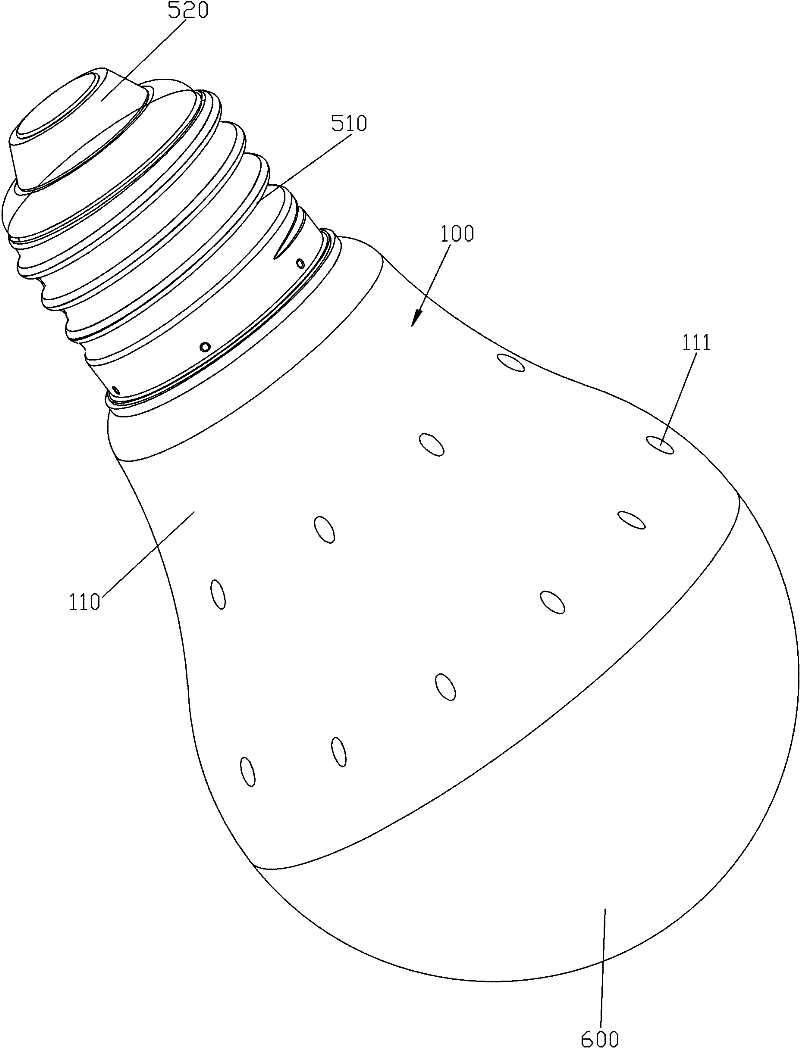

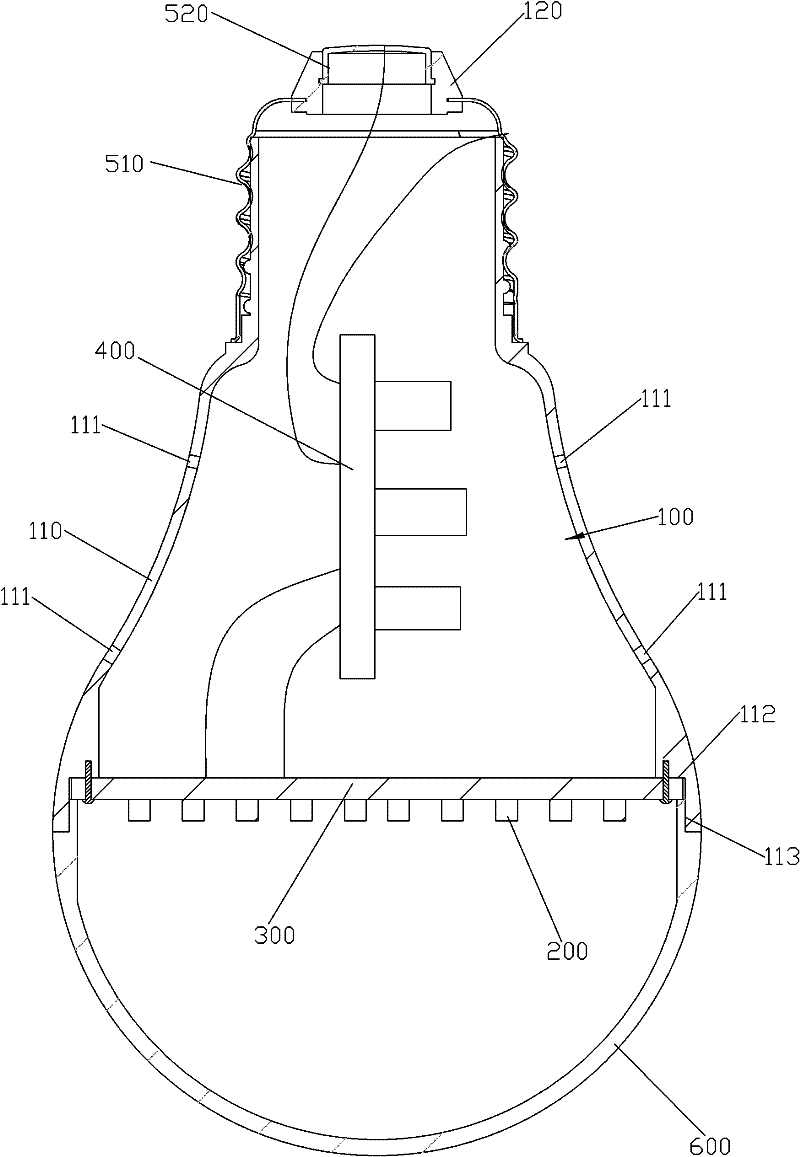

[0021] Please check figure 1 and figure 2 , a high heat dissipation LED light source, which includes a top cover 100 made of thermally conductive insulating plastic, an LED substrate 300 with an LED lamp 200, and a drive circuit board 400 that is electrically connected to the LED substrate 300 for driving the LED substrate 300 and a A transparent cover 600 made of PC.

[0022] The upper cover 100 at least includes a rotary sleeve 110 and a fastening base 120 fixed to the upper port of the rotary sleeve 110 . A lower port of the rotary sleeve 110 is provided with a step, and the step has a downward step surface 112 and an inner rotary surface 113 facing inward. In this embodiment, the rotating sleeve 110 is provided with a plurality of air holes 111 penetrating inside and outside. In this embodiment: the ventilation holes 111 are arranged in multiple rows spaced up and down, and the plurality of ventilation holes 111 in each row are arranged in a circular arrangement. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com