Corner connector for movable connection

A technology of movable connection and corner code, which is applied in the field of connection corner code, can solve the problems of inconvenient disassembly, easily damaged product quality, and affecting service life, etc., and achieve the effect of flexible and convenient adjustment, ensuring quality of use and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

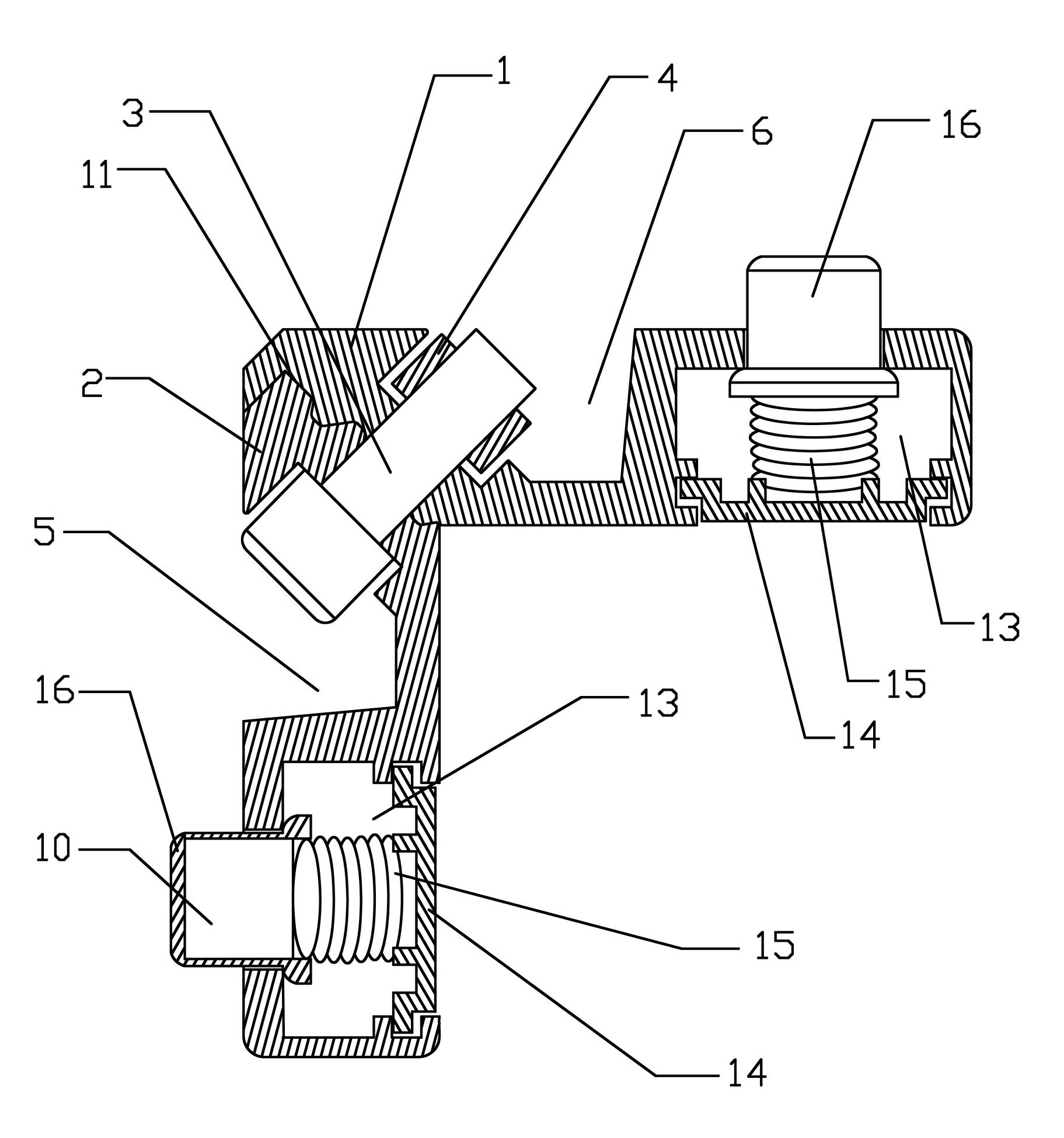

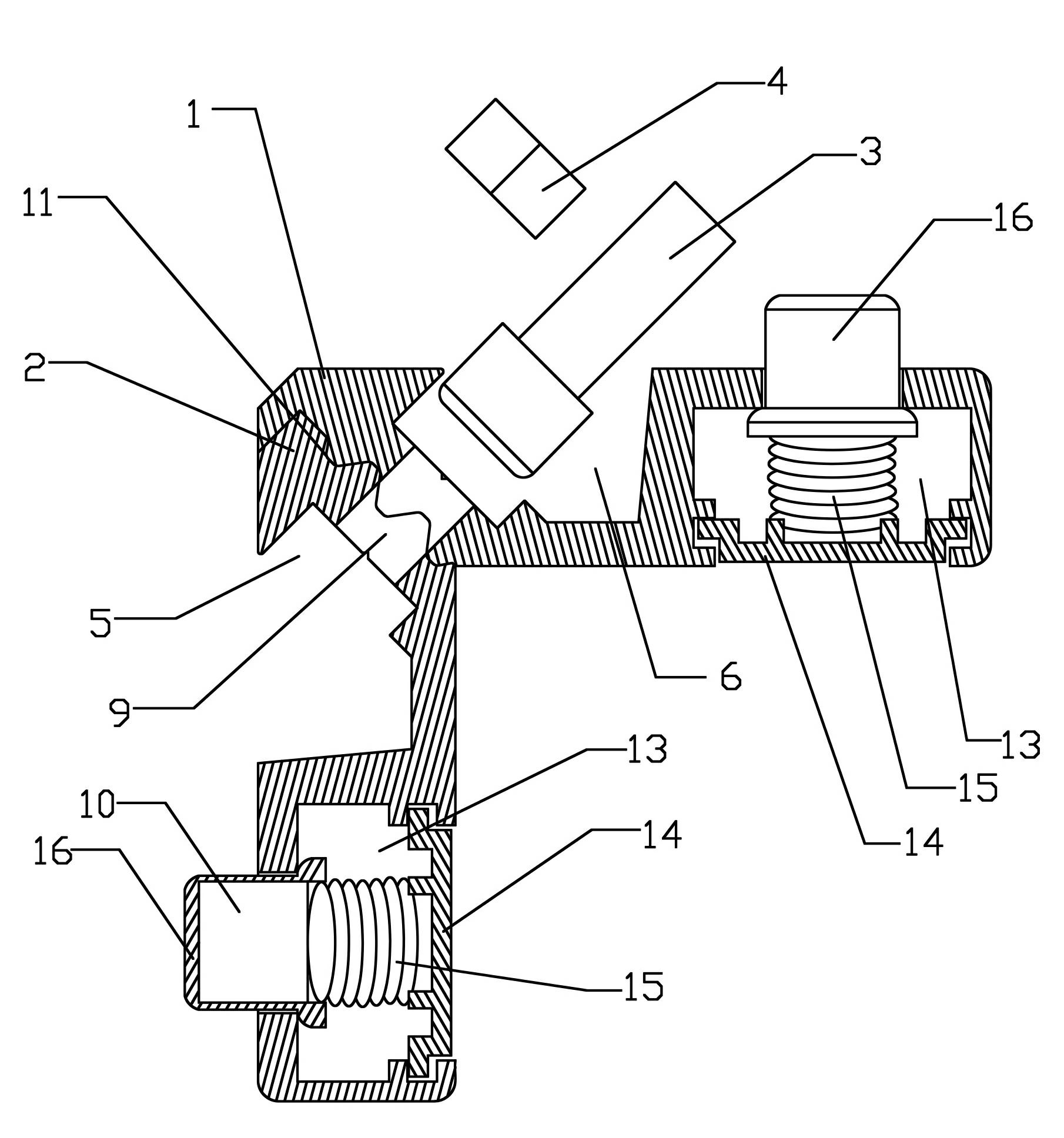

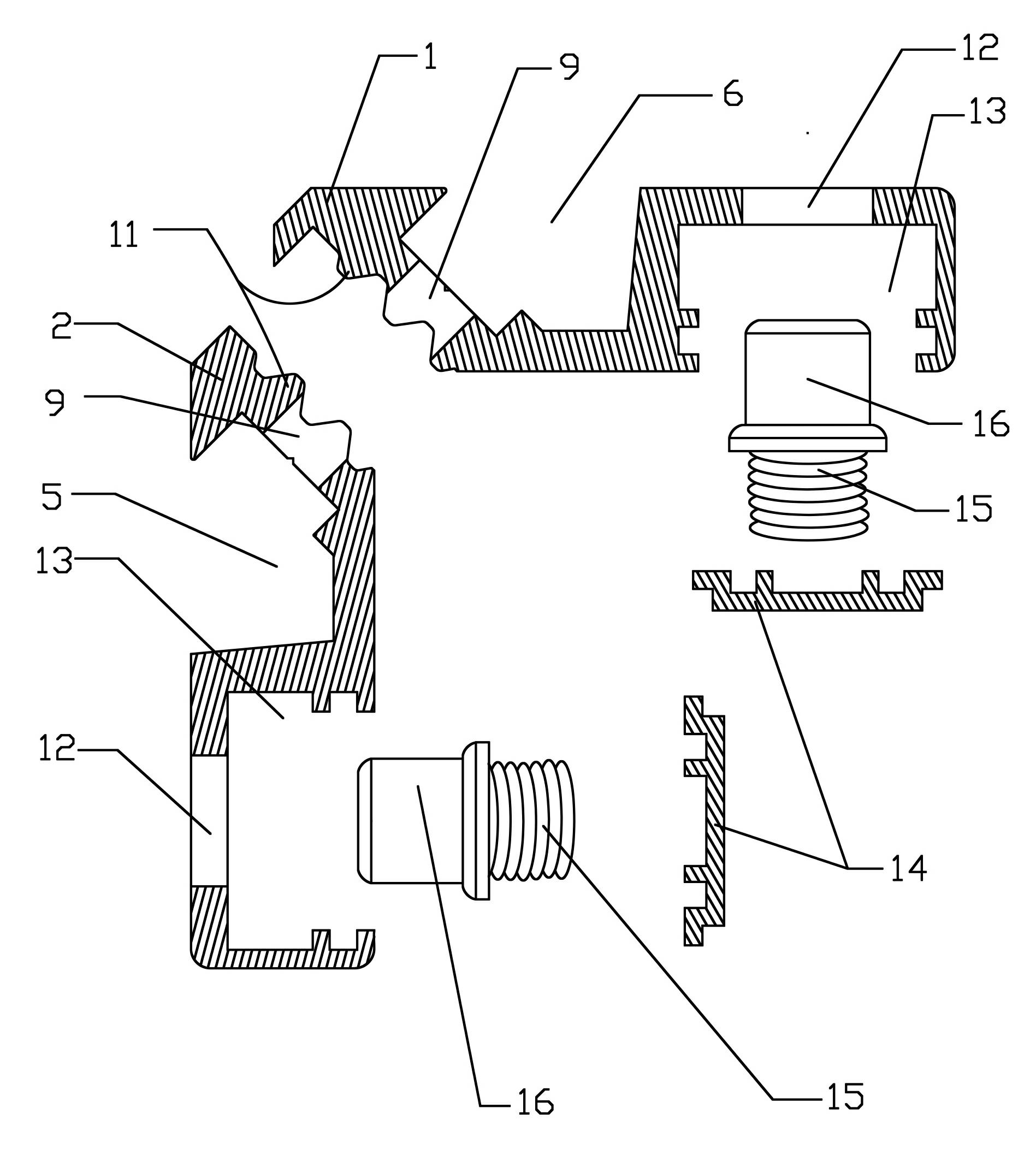

[0025] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

[0026] according to figure 1 , figure 2 , image 3 and Figure 4 As shown, the patent of the present invention is aimed at installing on the aluminum alloy door and window frame of the horizontal bracket 7 and the side bracket 8. The movable connection corner bracket includes a corner bracket base, and the corner bracket base includes a main connector 1 and a side connector 2 , the connection between the main connecting piece 1 and the side connecting piece 2 is provided with an adjusting piece 3 and a fixing piece 4 for adjusting the tightness, and the main connecting piece 1 and the side connecting piece 2 are respectively provided with a main installation groove and 5 side installation grooves 6, The adjusting part 3 respectively passes through the main mounting groove 5, the main connecting part 1, the side connecting part 2 and the side mounting groove 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com