Roof supporting structure of FRC (Glass-fiber Reinforced Composite) board and installation method thereof

A technology of supporting structure and top surface, applied in the direction of roof, building components, building structure, etc., can solve the problems of difficult installation and the inability of the back and ventral keels to be coplanar, and achieve simple and fast installation, strong applicability, and accelerated construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

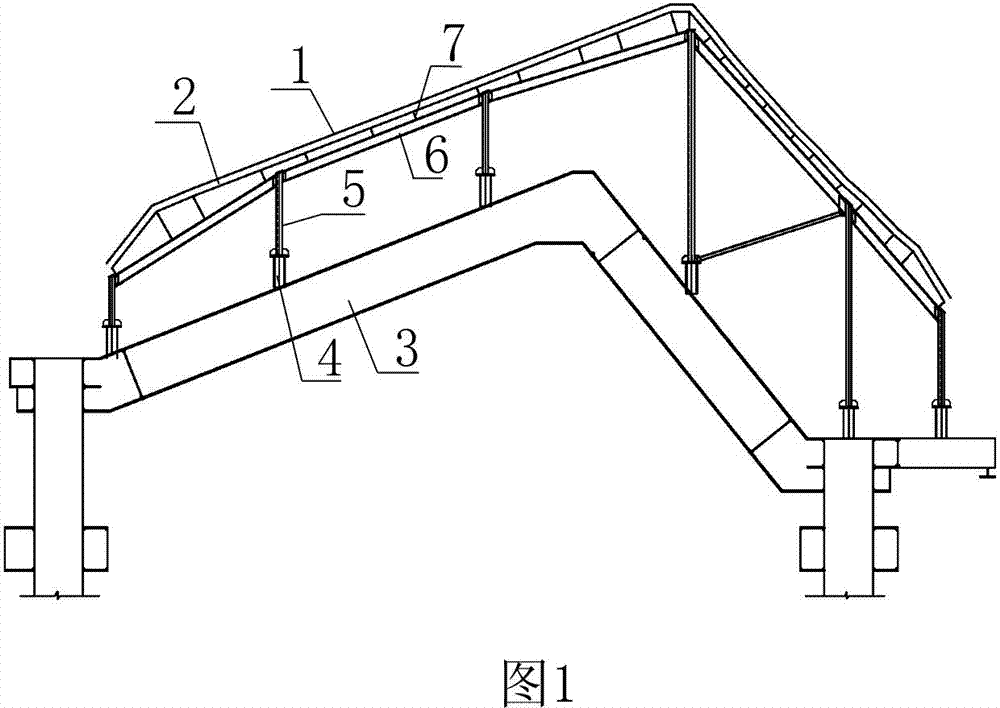

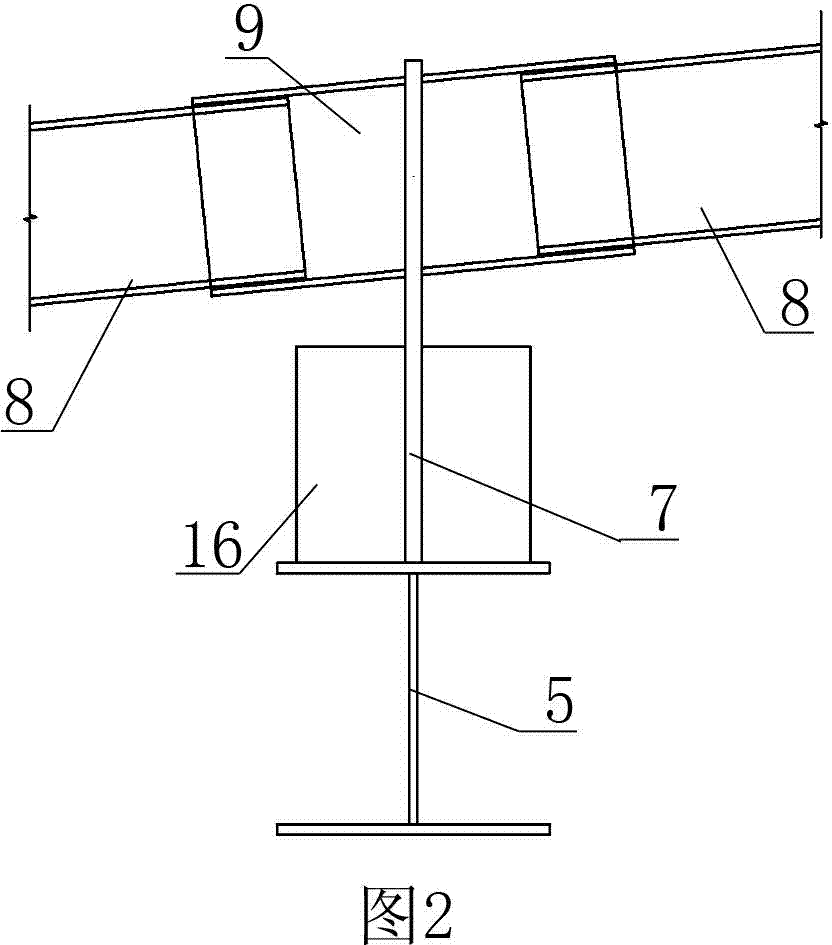

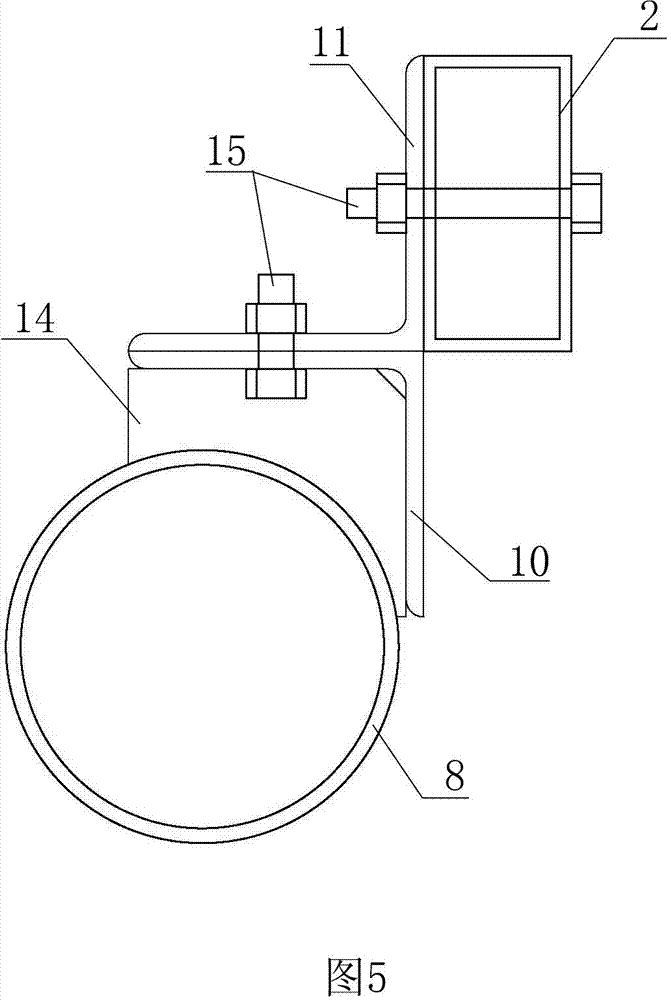

[0036] Examples see Figure 1~Figure 8 As shown, a GRC board roof support structure, the GRC board 1 is a space curved panel, including a dorsal-ventral keel 2 and a secondary support structure, the dorsal-ventral keel 2 is welded to the inner surface of the GRC board 1, and the dorsal-ventral keel 2 Supported on the secondary support structure, the secondary support structure is supported on the main steel structure 3. The secondary support structure includes the conversion short column 4, the support steel column 5, the support steel beam 6, the gusset 7 and the round tube purlin 8. The conversion stub column 4 is welded to the upper surface of the main steel structure 3 at intervals, the top surface of the conversion stub column is connected to the bottom surface of the supporting steel column, and the top of the supporting steel column is combined to form an integral beam-column structure through the supporting steel beam 6. The gusset plate 7 is vertically spaced on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com