On-line pretreatment device for copper-coated stainless steel wires

A technology of stainless steel wire and copper plating, applied in the field of pre-treatment devices and online pre-treatment devices, can solve the problems of large water consumption in washing tanks, easy to fall off, thin thickness, etc., and achieve the effect of stable thickness and improved bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

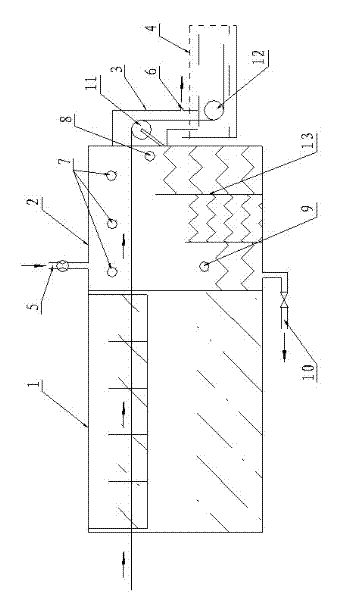

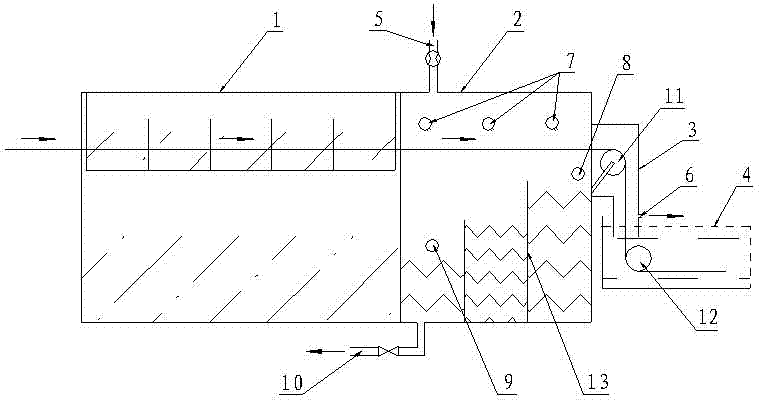

[0015] see figure 1 , the present invention relates to an online pretreatment device for copper-plated stainless steel wire, said device is arranged before the electroplating tank 4, and it includes a pickling tank 1, a water washing tank 2 and a sealed container 3, the top of the water washing tank 2 is closed, and the top is set There is an air inlet 5 for injecting reducing gas into the water washing tank. The upper part of the water washing tank 2 is provided with several spray ports 7, and the lower part is divided into several stepped areas by partitions 13 from front to back, and the first area is liquid The liquid level is the lowest, and the liquid level in the last area is the highest. The number of the spray ports 7 is equal to the number of the stepped areas. The several spray ports 7 are respectively located above the several stepped areas. The outlet 9 is provided with a water outlet 10 at the bottom, and the upper part of the last area is provided with a water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com