Epoxy resin adhesive modified by unsaturated polyimide and preparation method thereof

A technology of polyimide resin and epoxy resin, which is applied in the directions of epoxy resin glue, novolac epoxy resin adhesive and adhesive, can solve the problem of high cost of polyetherimide resin and unfavorable large-scale promotion. Application, limited reactive groups, etc., to achieve the effect of excellent adhesion, high practical value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The formula of modified epoxy resin adhesive of the present invention is as follows:

[0036]

[0037] Stir the above ingredients evenly at room temperature to obtain the unsaturated polyimide modified epoxy adhesive, which is designated as ES-MIE-1.

[0038] Take an appropriate amount of ES-MIE-1 adhesive, and evenly spread it on a standard iron sheet, stack it, clamp it, and put it into a blast oven for curing: start from room temperature and heat it up to 130°C, keep it warm for 1 hour, and continue to heat up to 150°C ℃, heat preservation reaction for 2 hours, continue to heat up to 175 ℃, heat preservation reaction for 3 hours, and naturally cool to room temperature.

[0039] The adhesive has good viscosity controllability, can be adjusted in a wide range, has good manufacturability, and has excellent bonding performance to iron sheets, and the tensile shear strength at room temperature (25°C) is as high as 17.3Mpa.

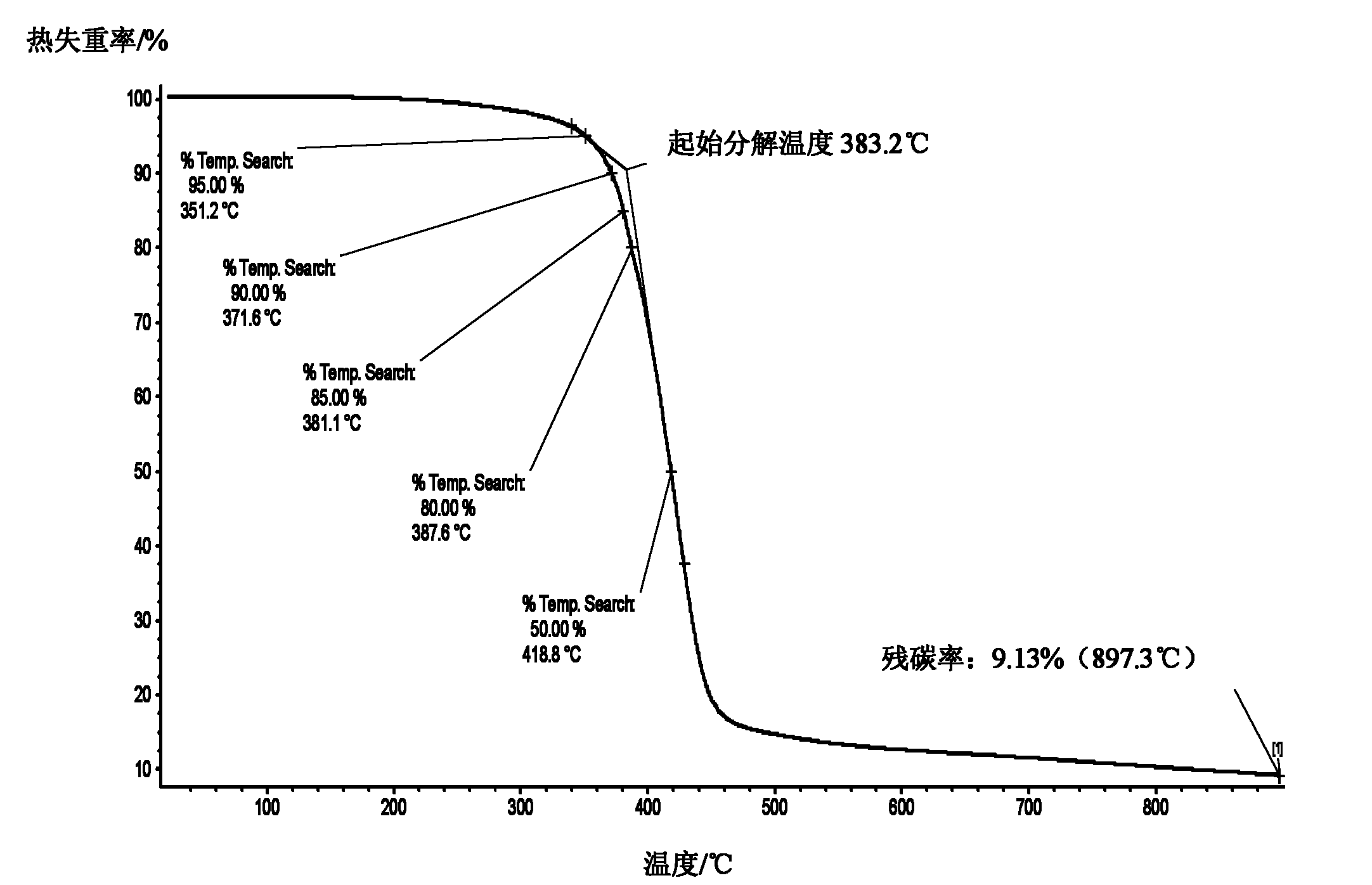

[0040] Take an appropriate amount of unsatu...

Embodiment 2

[0044] The formula of modified epoxy resin adhesive of the present invention is as follows:

[0045]

[0046] Stir the above ingredients evenly at room temperature to obtain the unsaturated polyimide modified epoxy adhesive, which is designated as ES-MIE-2.

[0047] Take an appropriate amount of ES-MIE-2 adhesive, and evenly spread it on a standard iron sheet, laminate, clamp, and put it into a blast oven for curing: start from room temperature to 130°C, keep warm for 1 hour, and continue to heat up to 150°C ℃, heat preservation reaction for 2 hours, continue to heat up to 175 ℃, heat preservation reaction for 3 hours, and naturally cool to room temperature.

[0048] The adhesive has good viscosity controllability, can be adjusted in a wide range, has good manufacturability, and has excellent bonding performance to iron sheets, and the tensile shear strength at room temperature (25°C) is as high as 16.8Mpa.

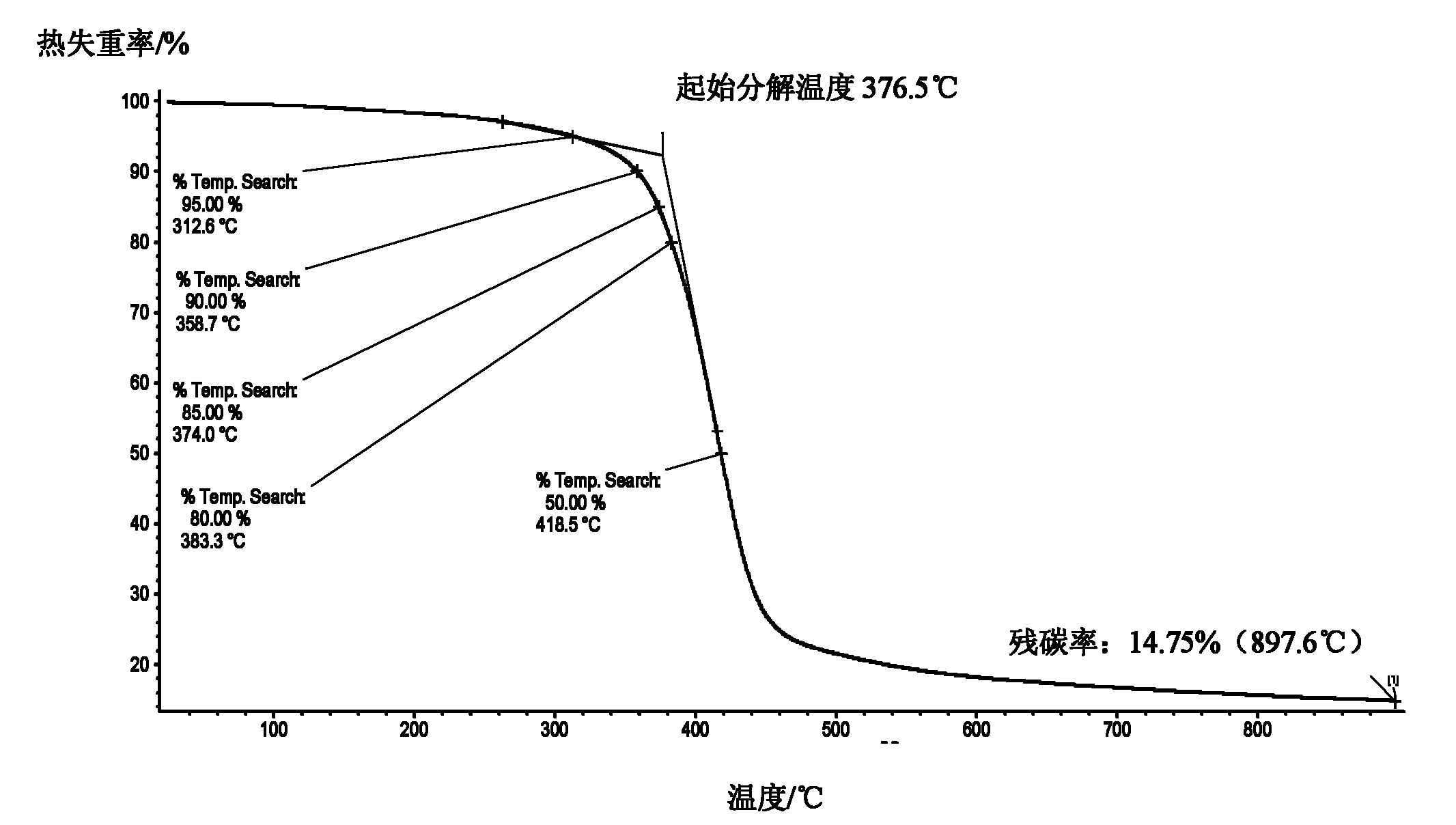

[0049] Take an appropriate amount of unsaturated polyimide modif...

Embodiment 3

[0053] The formula of modified epoxy resin adhesive of the present invention is as follows:

[0054]

[0055] Stir the above ingredients evenly at room temperature to obtain the unsaturated polyimide modified epoxy adhesive, which is designated as ES-MIE-3.

[0056] Take an appropriate amount of ES-MIE-3 adhesive, and evenly spread it on a standard iron sheet, laminate, clamp, and put it into a blast oven for curing: start from room temperature to 130°C, keep warm for 1 hour, and continue to heat up to 150°C ℃, heat preservation reaction for 2 hours, continue to heat up to 175 ℃, heat preservation reaction for 3 hours, and naturally cool to room temperature.

[0057] The adhesive has good viscosity controllability, can be adjusted in a wide range, has good manufacturability, and has excellent bonding performance to iron sheets, and the tensile shear strength at room temperature (25°C) is as high as 16.0Mpa.

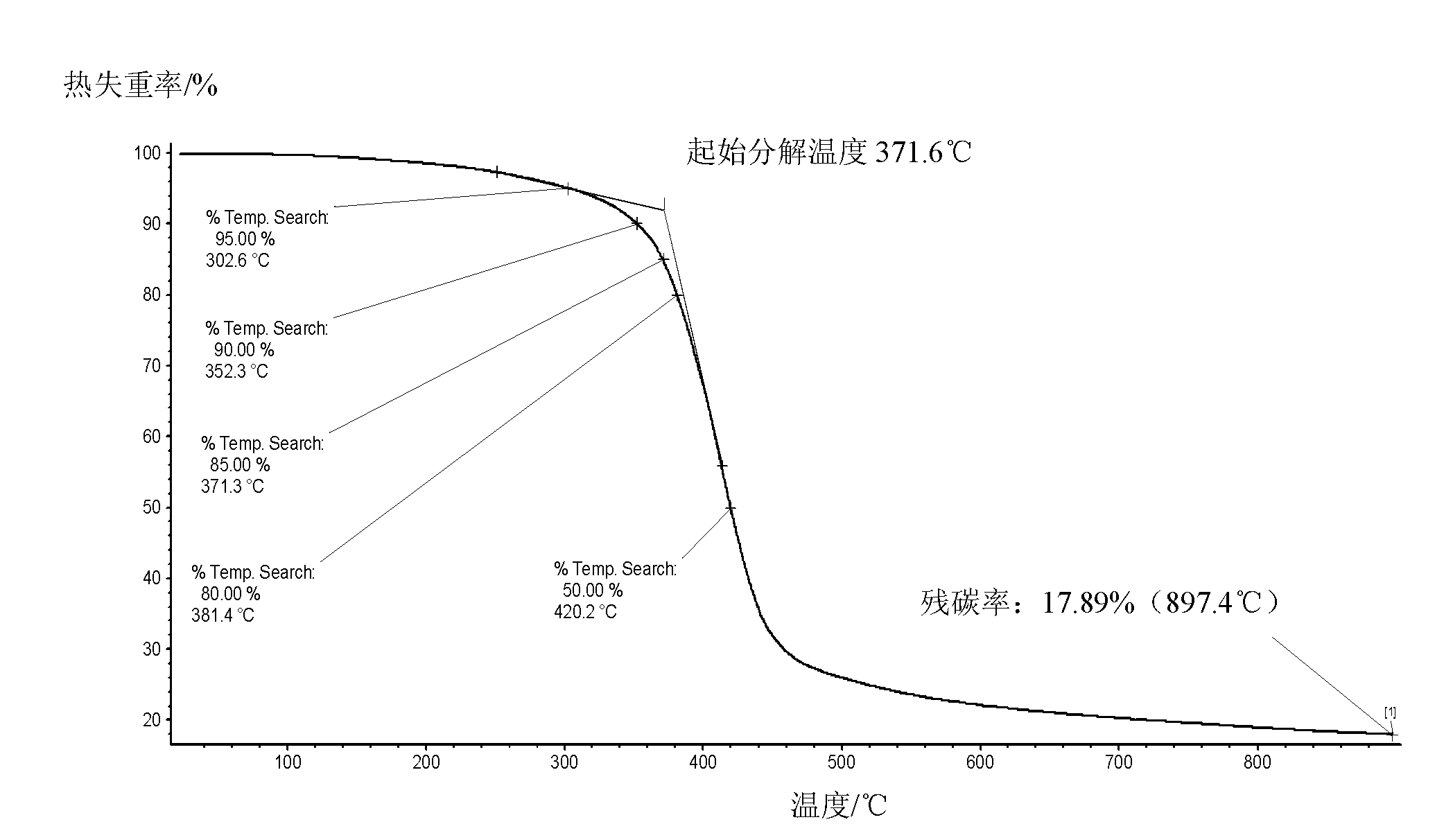

[0058] Take an appropriate amount of unsaturated polyimide modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com