Thermosetting moisture-resistant welding seam sealant

A sealant and thermal hardening technology, which is applied in the field of weld sealants, can solve the problems of insufficient waterproof and moisture resistance, waste of labor and material resources, and unsatisfactory waterproof and moisture resistance functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a detailed description based on Examples and Comparative Examples.

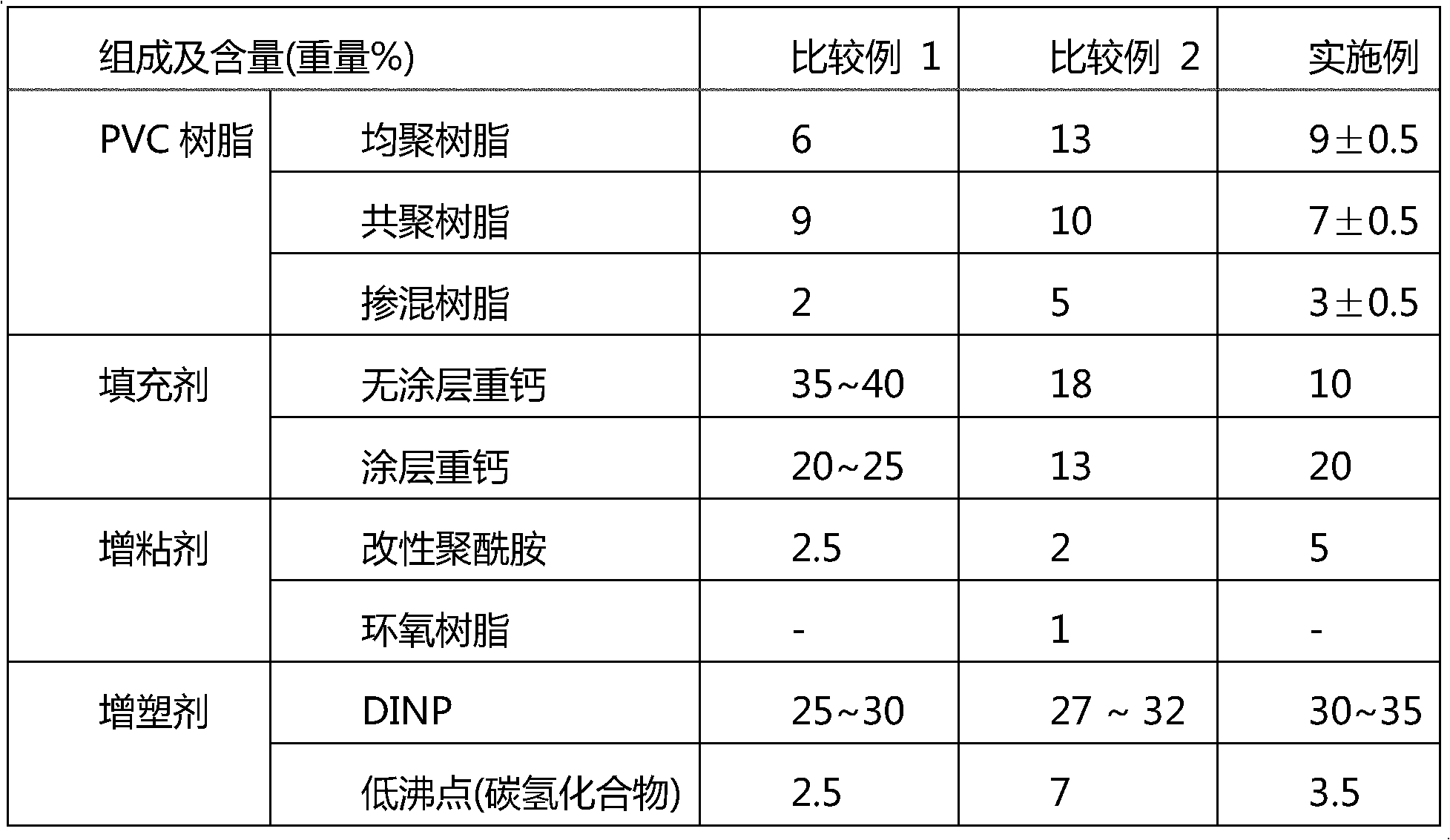

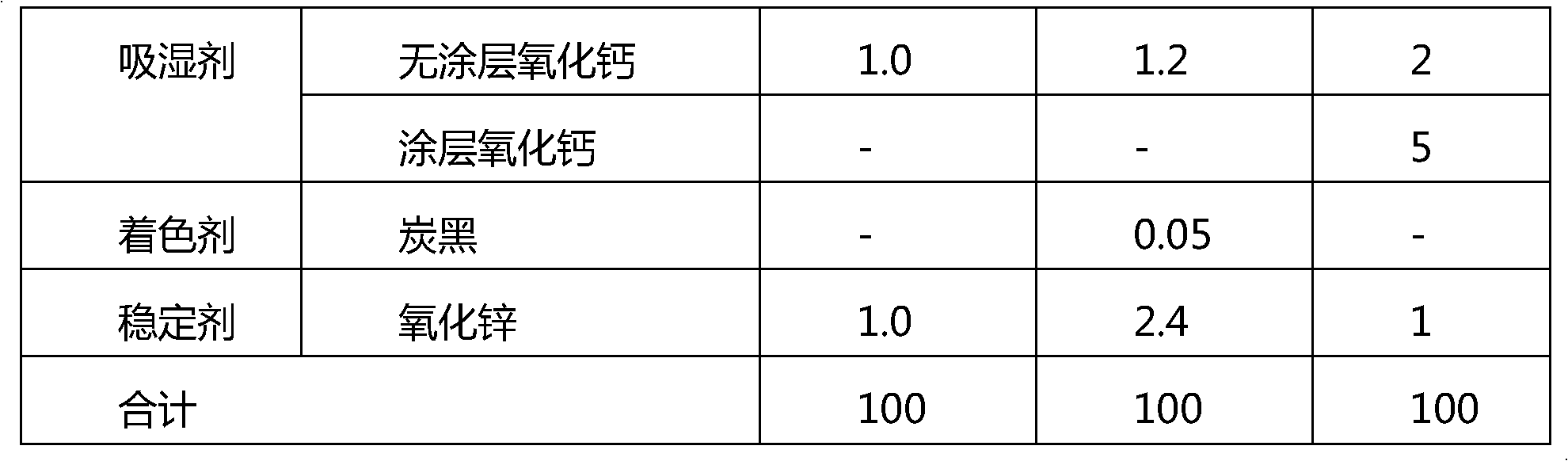

[0015] Table 1 is a comparison table of each component composition of the embodiment and comparative examples 1 and 2.

[0016]

[0017]

[0018] Table I

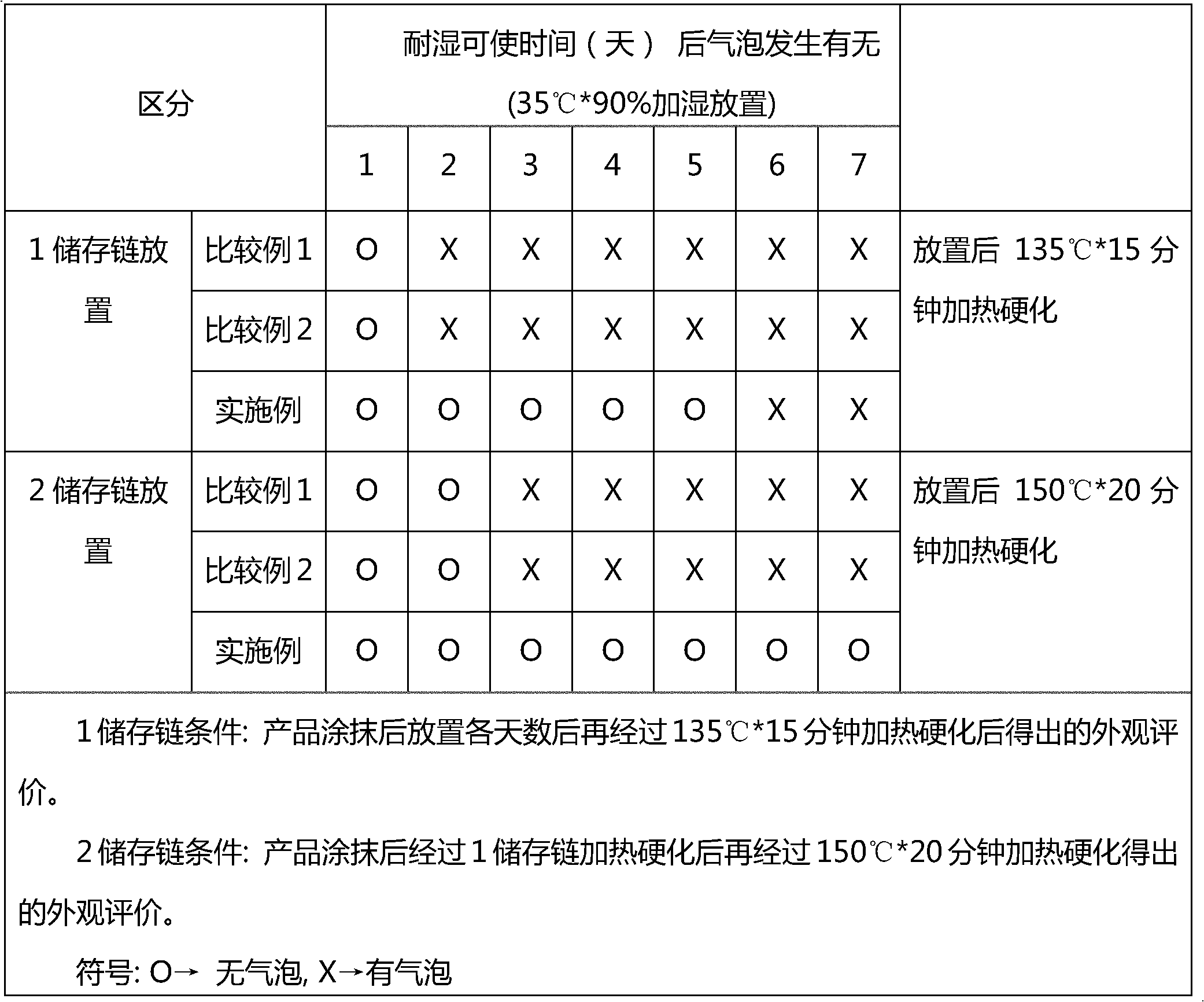

[0019] Table 2 is the moisture-resistant time test. Comparative examples 1, 2 and the examples are made of test pieces by the same smearing method, and then stored in 1, 2 storage chains. After being placed for 7 days, Comparative Examples 1, 2 and Examples were stored for different days in each storage chain to evaluate the appearance of bubbles after heating and hardening.

[0020]

[0021] Table II

[0022] According to the results in Table 2, it can be seen that under high temperature and high humidity conditions, comparative examples 1 and 2 will have poor appearance quality after being placed in the 1 storage chain for 24 hours, and after being placed in the 2 storage chain for 48 hours, while the examples are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com