Positioning device for electrode welding of semiconductor laser

A positioning device and laser technology, applied in auxiliary devices, welding equipment, metal processing, etc., can solve the problems of different sizes that are prone to shaking, difficult welding of heat sink electrodes, poor solder joint consistency, etc., and solve the problem of heat sink thickness. , improve the welding quality, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

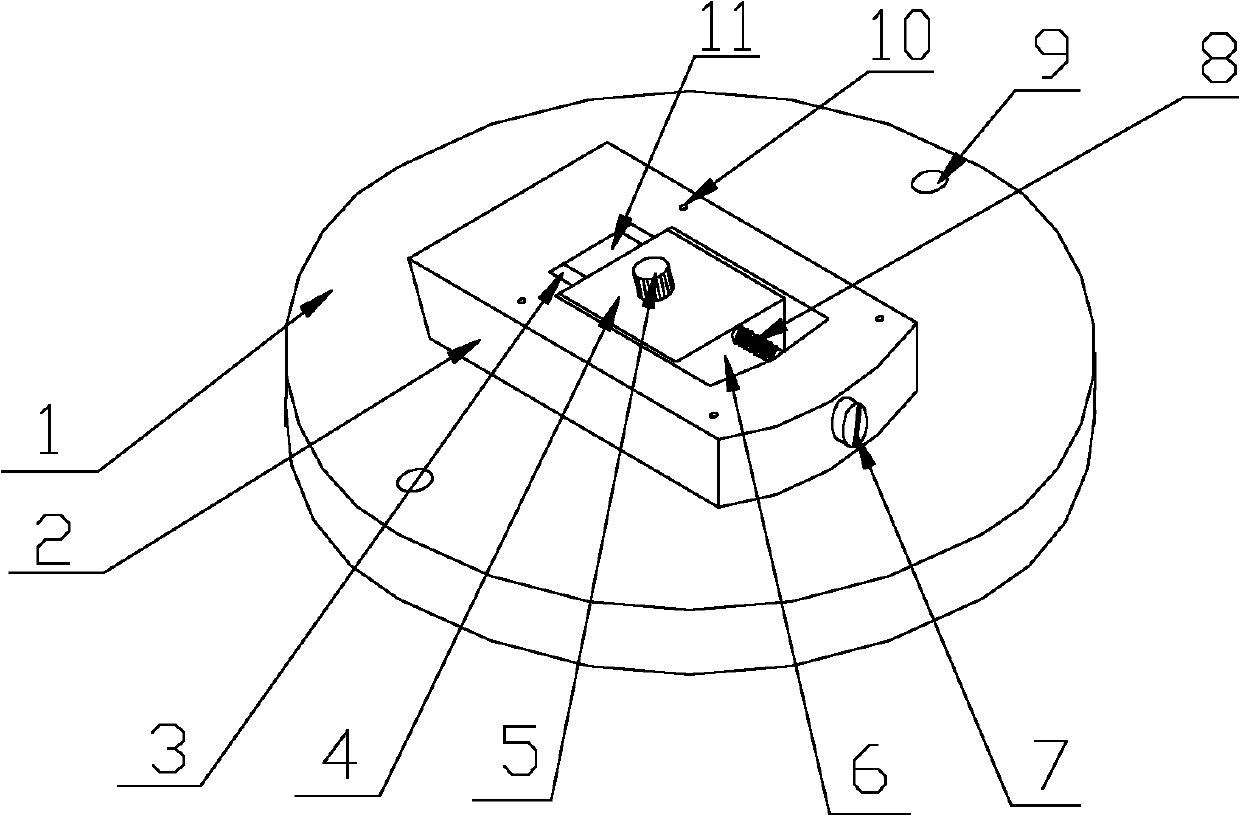

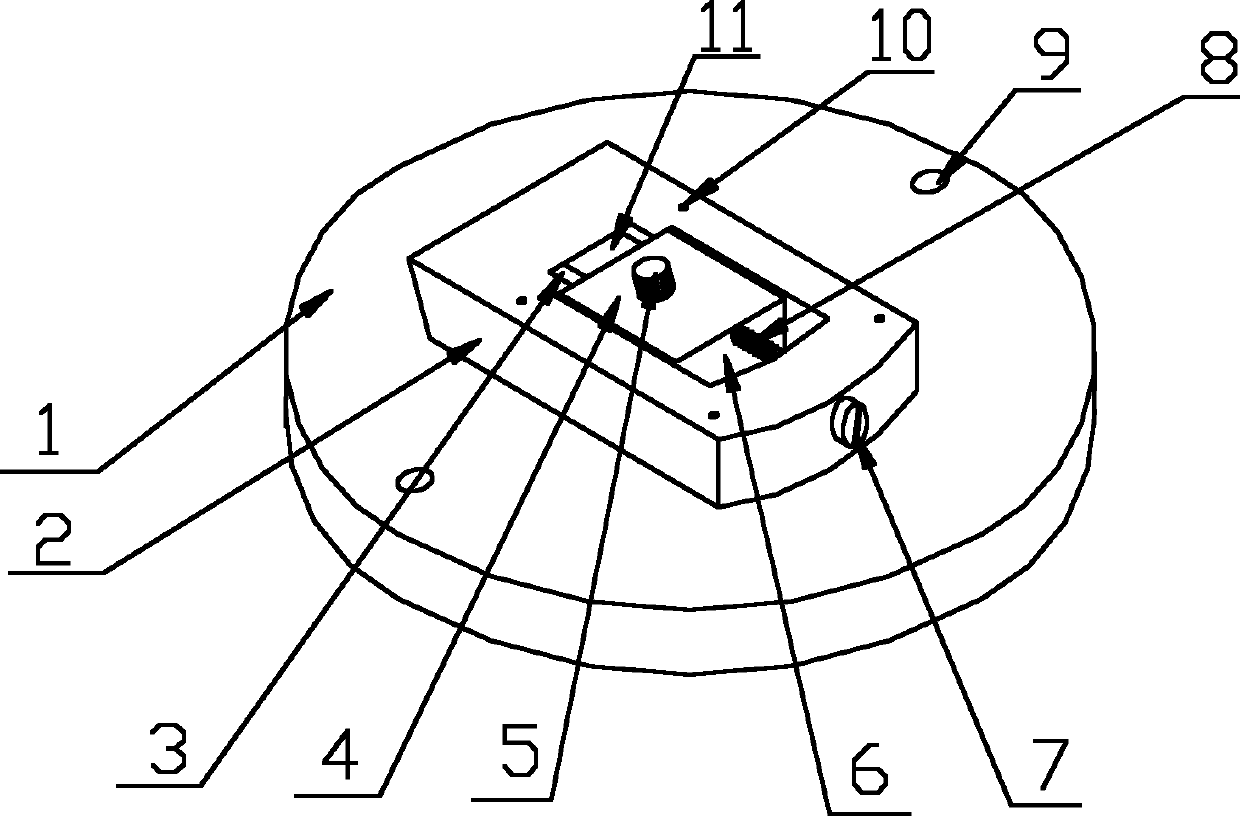

[0019] The chassis 1, base 2, pull plate 4, handle 5, fixing bolt 7, chassis fixing screw 9, and base fixing screw 10 in the positioning device of the present invention are all made of metal materials, such as materials such as stainless steel, copper, and oxygen-free copper. The spring 8 is made of manganese steel, and the heat sink 11 is made of metal oxygen-free copper. The parallelism of the surface of the device chassis is required to be 0.6 microns, the parallelism of the bottom of the heat sink is required to be 0.5 microns, and the electrode welding temperature is 120 ° C.

[0020] The size of the heat sink groove 3 can be adjusted according to the size of the heat sink 11 , and the tension of the pull plate 4 can be adjusted according to the diameter and length of the spring 8 .

Embodiment 2

[0022] The present invention can be applied to welding devices of different chip lengths and upper and lower electrodes of high-power semiconductor lasers, only needing to adjust the size of the heat sink 3 and the heating temperature of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com