Rapid clamping mould box for battery pack welding

A kind of battery pole and fast technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of unreliable self-locking performance, short clamping stroke, etc., to achieve the effect of long clamping stroke and reducing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

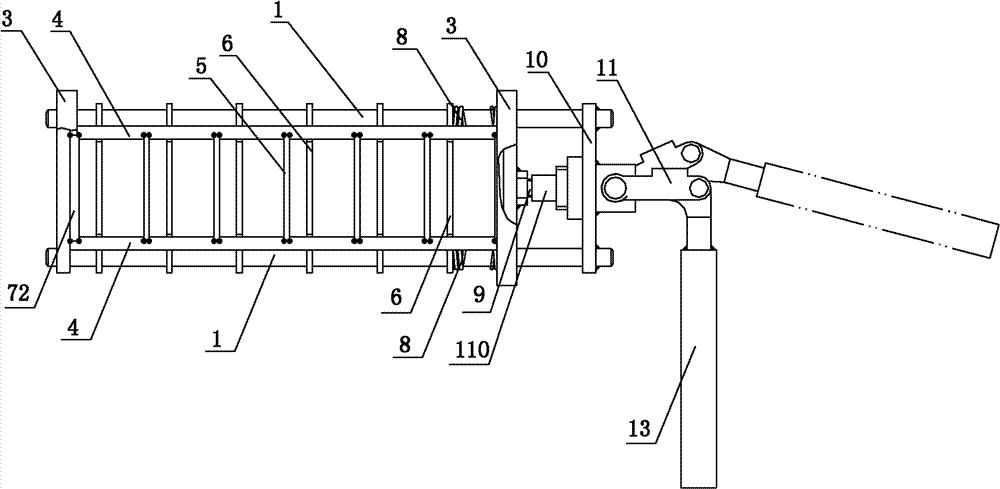

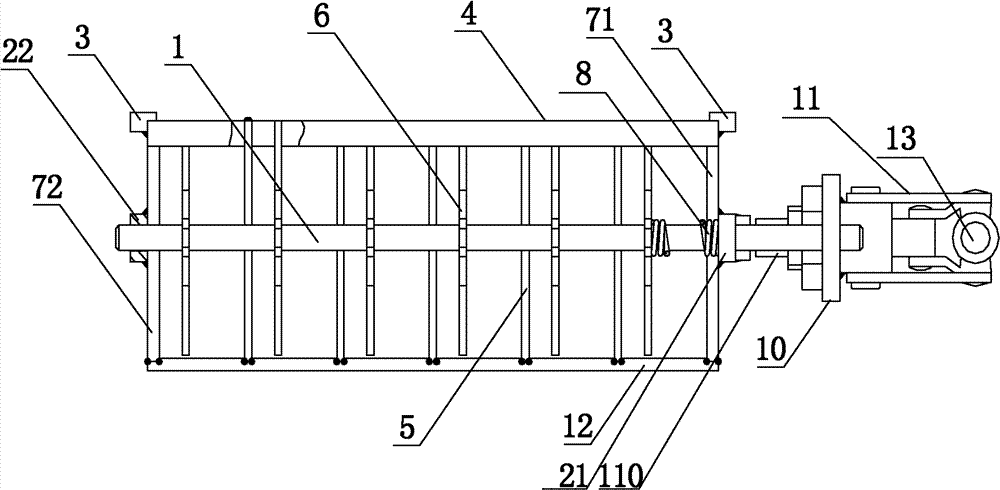

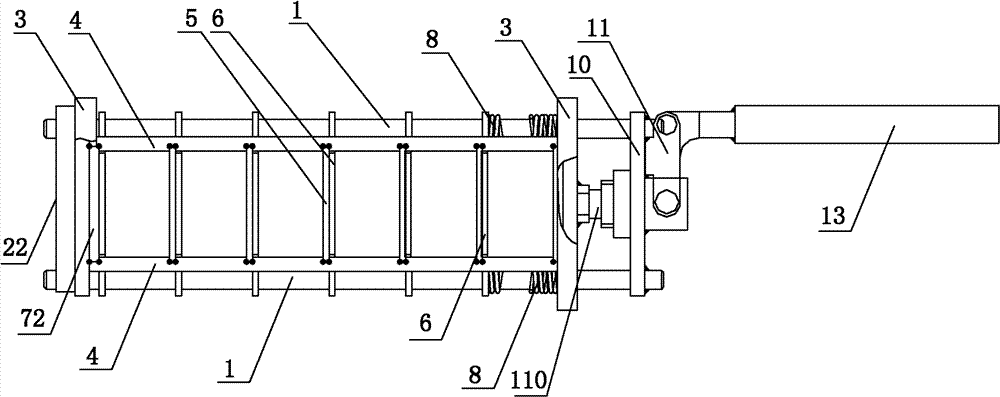

[0023] Please refer to figure 1 with figure 2 , The quick clamping mold box for battery pole group welding in this embodiment includes a movable mold box for containing the battery pole group, and a clamping mechanism for clamping the battery pole group contained in the movable mold box. Wherein, movable mold box is by base plate 12, is respectively fixed on the front end plate 71 and rear end plate 72 of this base plate 12 front and rear ends, and is arranged on this base plate 12 left and right sides, and is fixedly connected with front end plate 71 and rear end plate 72 Two side plates 4 are enclosed and formed, and a plurality of baffle plates 5 parallel to the front end plate 71 and the rear end plate 72 are fixed between the two side plates 4; wherein, the clamping mechanism includes a connecting plate 10, which is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com