Sterilizing stripper dedicated for oilfield injection water and preparation method thereof

A technology of reinjecting water and stripping agents in oilfields, applied in the direction of fungicides, botany equipment and methods, and biocides, which can solve problems such as poor water quality, unsatisfactory stripping effects, and great harm, and achieve improved stripping performance and stripping effects Visible, strong bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

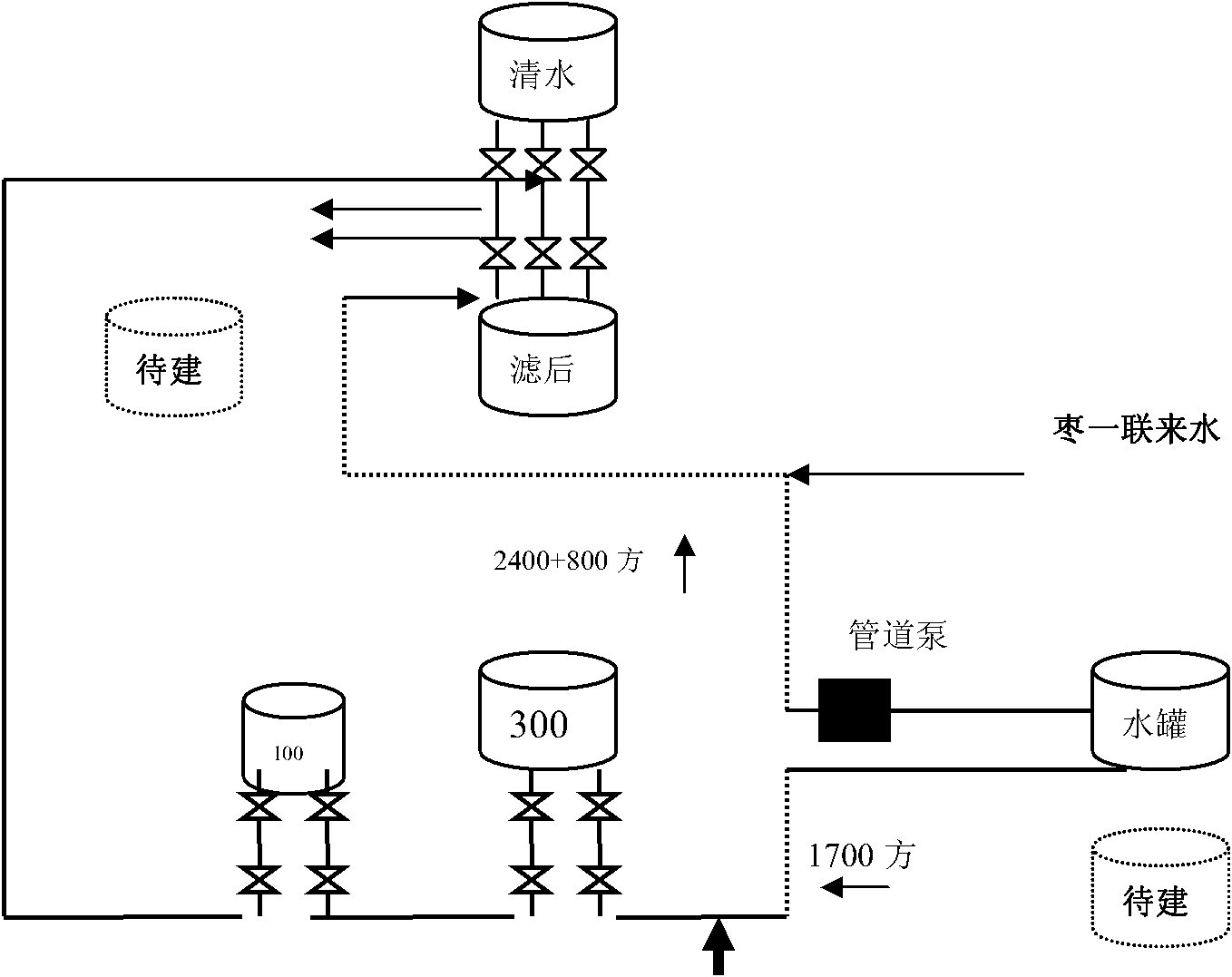

Image

Examples

Embodiment 1

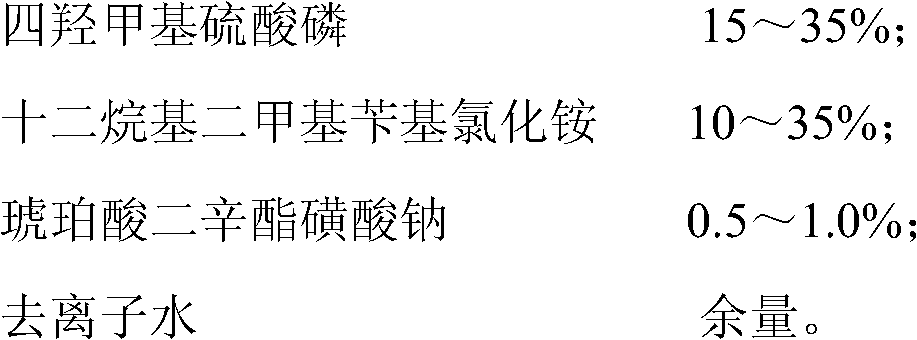

[0018] A special bactericidal stripping agent for oil field reinjection water, which is prepared from the following raw materials in weight percentage:

[0019]

[0020] Preparation method: After adding deionized water into the reaction kettle, add tetrakis hydroxymethyl phosphorus sulfate, dodecyl dimethyl benzyl ammonium chloride and dioctyl sodium sulfosuccinate, and stir for 45 minutes at room temperature.

Embodiment 2

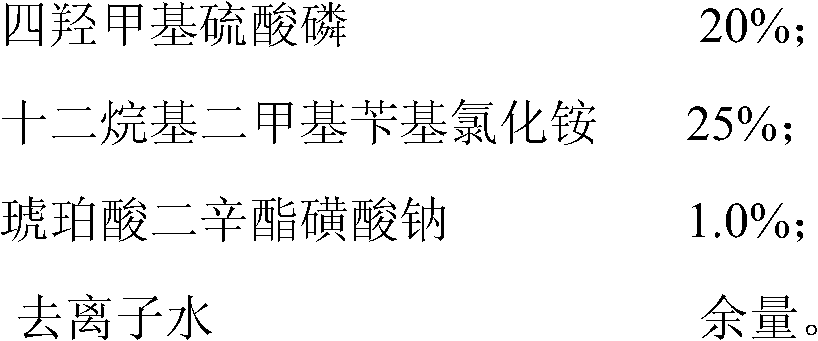

[0022] A special bactericidal stripping agent for oil field reinjection water, which is prepared from the following raw materials in weight percentage:

[0023]

[0024] Preparation method: After adding deionized water into the reaction kettle, add tetrakis hydroxymethyl phosphorus sulfate, dodecyl dimethyl benzyl ammonium chloride and dioctyl sodium sulfosuccinate, and stir for 45 minutes at room temperature.

Embodiment 3

[0026] A special bactericidal stripping agent for oil field reinjection water, which is prepared from the following raw materials in weight percentage:

[0027]

[0028]

[0029] Preparation method: After adding deionized water into the reaction kettle, add tetrakis hydroxymethyl phosphorus sulfate, dodecyl dimethyl benzyl ammonium chloride and dioctyl sodium sulfosuccinate, and stir for 45 minutes at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com