Method for measuring combustion performance of powder or liquid sample by utilizing cone calorimeter

A cone calorimeter and liquid sample technology, applied in the direction of material thermal development, etc., can solve problems such as difficulty in ensuring experimental reproducibility, time-consuming, labor-intensive costs, and harsh conditions, so as to save sample consumption and reduce production processes , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] By adopting the test method designed by the invention, the cone calorimetric test can be directly performed on the wood powder. First, dry the wood powder and mix the flame retardant evenly, fully grind, and then weigh 14g of the sample to be tested and place it in a crucible covered with aluminum foil, and conduct the test in accordance with the operating procedures of the cone calorimeter.

[0023] Table 1 Cone calorimetric test data comparison between poplar wood flour and poplar board

[0024]

[0025] It can be seen from Table 1 that the reproducibility of the data obtained from the cone calorimetry test with poplar wood powder is better than that of the data obtained with poplar wood board. Under the same experimental conditions, the peak standard deviation of heat release rate S (pkHRR) of poplar wood powder is 5.71, which is much smaller than that of poplar wood board (pkHRR) 12.19; the standard deviation of average heat release rate S (aHRR) of poplar wood powder is...

Embodiment 2

[0029] Epoxy resin is an important type of thermosetting resin. It has the characteristics of low curing shrinkage, low curing pressure, basically no volatile matter, good bonding performance, and excellent bonding strength to the surface of metal and non-metal materials. A major composite material matrix. The epoxy resin itself is liquid and needs to be used in conjunction with the curing agent. It can be cured into a common solid epoxy resin material after a certain time at a certain temperature. The sample preparation process is complicated, especially for high-temperature curing agents, the required curing conditions More demanding. Therefore, it is difficult to study the combustion performance of epoxy resin materials through cone calorimetric test in the laboratory.

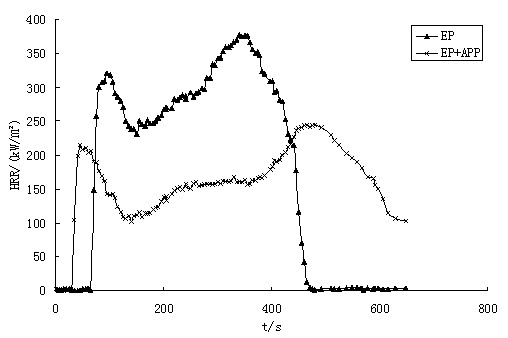

[0030] By adopting the crucible and testing method designed by the invention, the conical calorimetric test can be directly performed on the liquid epoxy resin. First, the first group weighs 10g epoxy resin ...

Embodiment 3

[0032] Using the crucible and testing method designed by the invention, a cone calorimetric test is performed on the solid epoxy resin.

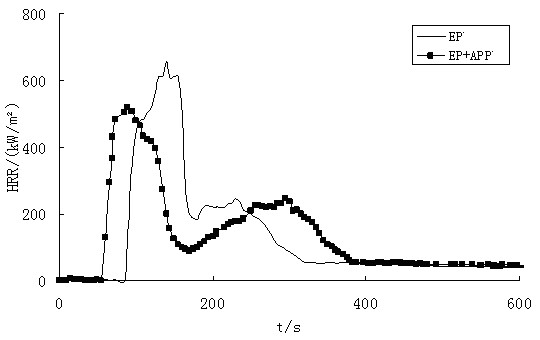

[0033] First, weigh 10g epoxy resin, grind it, and screen at the same time; in the second group, weigh 10g epoxy resin and 3g ammonium polyphosphate (APP) flame retardant, grind it, sieving, then mix well, and transfer to the aluminum foil covered In the crucible, use an analytical balance to accurately weigh, calculate the mass of the sample, and then perform the test in accordance with the operating procedure of the cone calorimeter.

[0034] image 3 It is the heat release rate (HRR) curve diagram of the flame-retardant and non-flame-retardant epoxy resin powder samples in the cone calorimetry test. Comparing the two curves, the change rule is basically the same as that of the liquid epoxy resin. This method is used to explore the influence of flame retardant on the combustion performance of epoxy resin and the flame retardant mechanism, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com