Vacuum saturation device for soil engineering centrifugal model test

A technology of model testing and geotechnical centrifugation, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the specific negative pressure difference cannot be set, the saturation time is short, and the volume of the saturated object is small, so as to ensure the quality and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

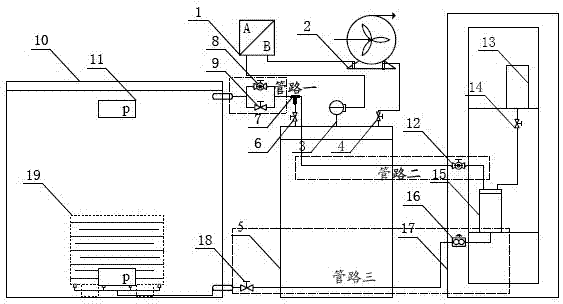

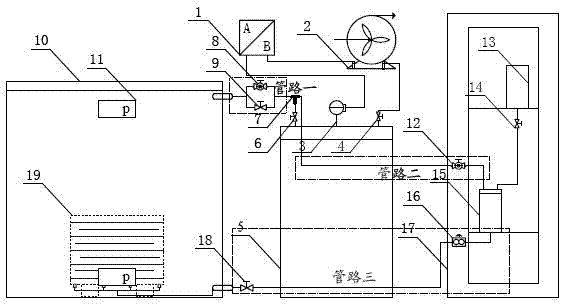

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] refer to figure 1 The geotechnical centrifugal model test vacuum saturation device of the present invention includes a vacuum pump 2 that provides power for the whole set of devices. The water vapor separation tank 5 of the energy device is connected, and the water vapor separation tank 5 is connected with the power control cabinet through the electric contact vacuum pressure gauge 3. The limit value is closed and started in real time; the top of the water-steam separation tank 5 is provided with a three-way valve 7, and the air inlet of the three-way valve 7 is installed on the water-steam separation tank 5; the first of the three-way valve 7 The gas outlet is connected to the saturation box 10 for providing the saturation space through a pipeline, and the saturation box 10 is separated from the whole set of devices, and a precision pressure gauge 11 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com