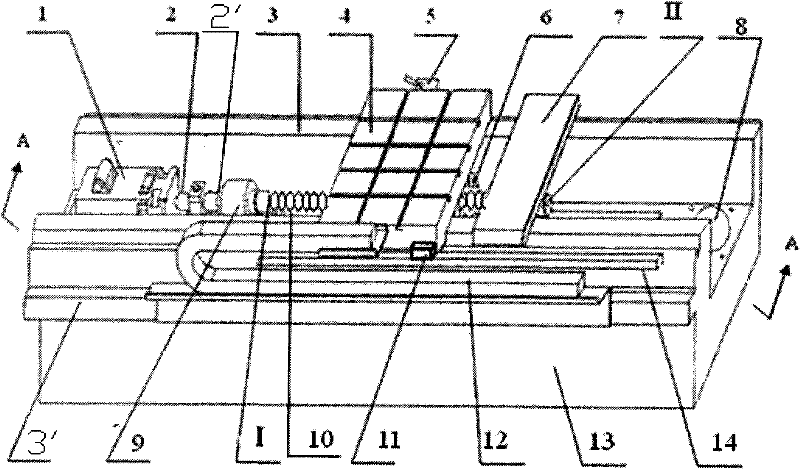

Device for detecting comprehensive performance of high-speed precision ball screw pair

A technology of ball screw pair and comprehensive performance, which is applied in the field of high-speed precision transmission pair comprehensive performance detection device, can solve the problems of lack of ball screw pair, etc., and achieve the effect of fast response speed, stable performance and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

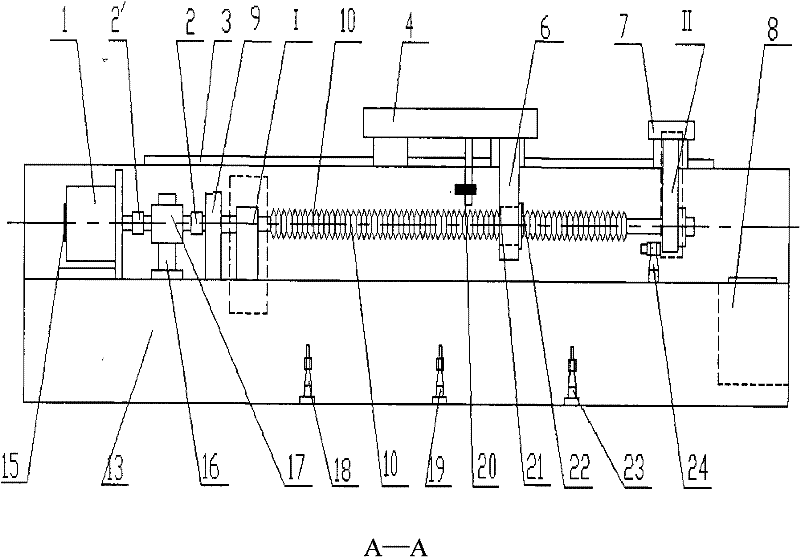

Method used

Image

Examples

specific Embodiment approach

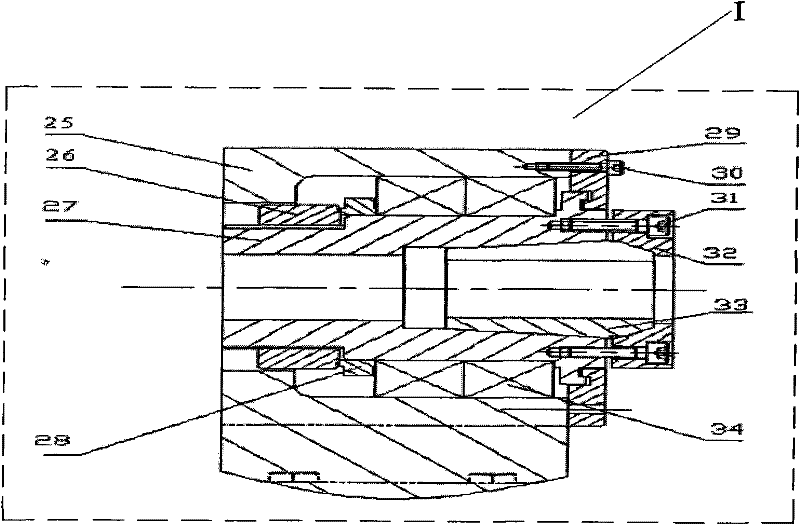

[0011] The ball screw pair to be tested adopts the installation mode of left fixing and right floating. The fixed support I at the left end is directly connected with the servo motor 1 through the coupling 2, and the fixed support I is installed in the left shaft sleeve 27 through the tensioning sleeve 33 at the fixed end. Then the fixed end deep groove ball bearing 34 is installed on the left end bearing seat 25, the right end of the fixed end deep groove ball bearing is stuck on the left end bearing seat 25, the left end is locked by the fixed end lock nut 26 through the fixed end spacer 28, and fixed The end small gland 32 fixes the fixed end tensioner 34 in the left shaft sleeve 27 through the fixed end end cap socket head cap screw 31, and the fixed end small gland 32 fixes the left shaft sleeve 27 in the left end bearing seat 25 through screws; The right end floating support II of the ball screw pair is installed in the right shaft sleeve 36 through the floating end tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com