Independent flameout alarm monitoring system of multi-combustor for combustion applying computer program

A computer program, flameout alarm technology, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of increasing boiler accidents, missed inspections, missed reports, and inability to determine the abnormality of burner combustion, etc., to reduce manual labor intensity , the effect of reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

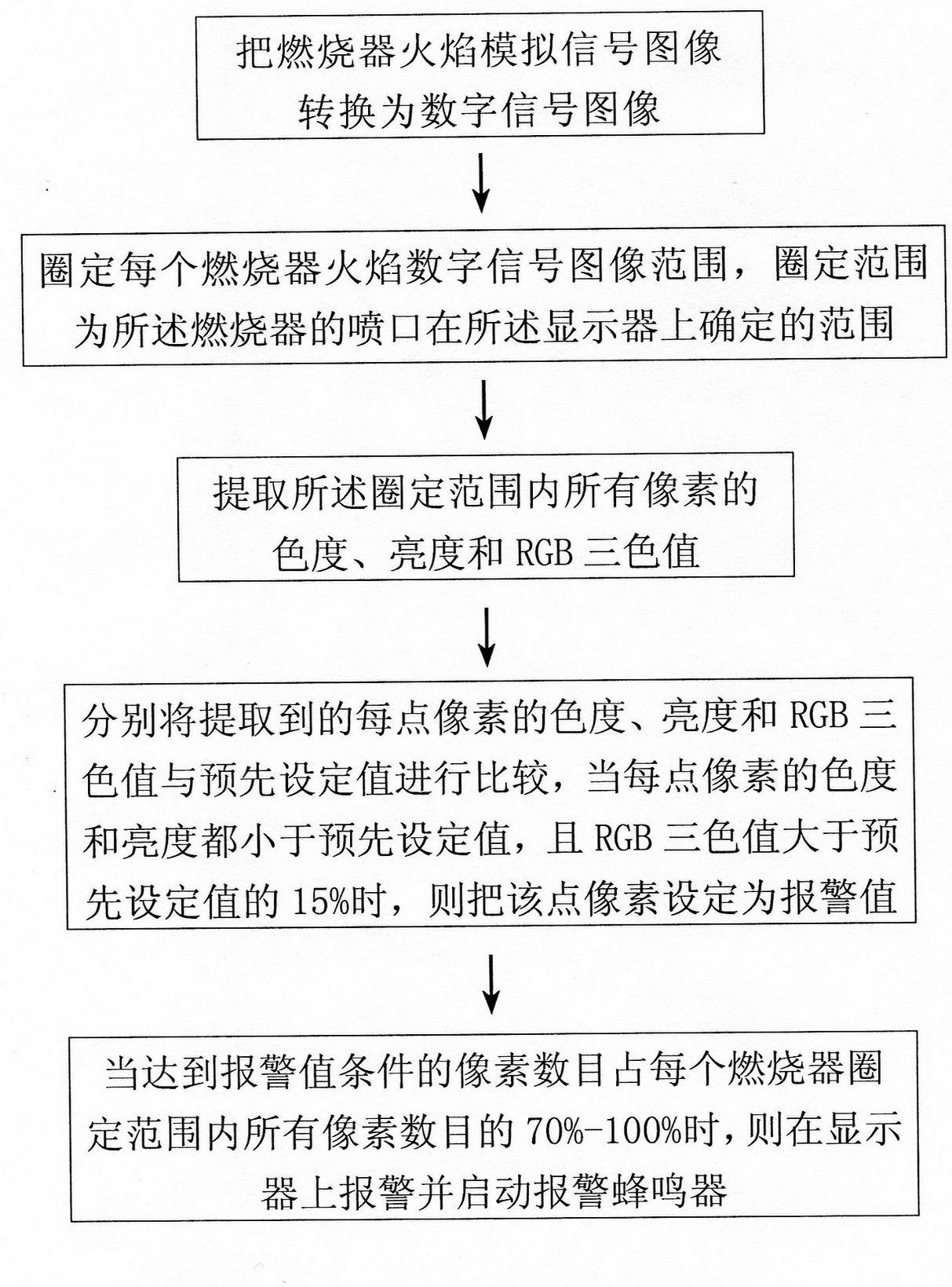

[0016] Referring to the accompanying drawings, the present invention adopts a computer program to carry out a multi-burner independent flameout alarm monitoring system for a furnace. Firstly, the collected burner flame analog signal image is converted into a digital signal image and sent to the display, and then each frame is delineated on the display. A burner flame digital signal image range, the delineated range is the range determined by the nozzle of the burner on the display, and then the chromaticity, brightness and RGB three-color values of all pixels in the delineated range are extracted, and then respectively The extracted chromaticity, brightness and RGB three-color value of each pixel are compared with the preset value, when the chromaticity and brightness of each pixel are less than the preset value, and the RGB three-color value is greater than the preset value When it is 15% of the alarm value, set the pixel at this point as the alarm value, and then judge whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com