Dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of continuous cast blank and preparation method thereof

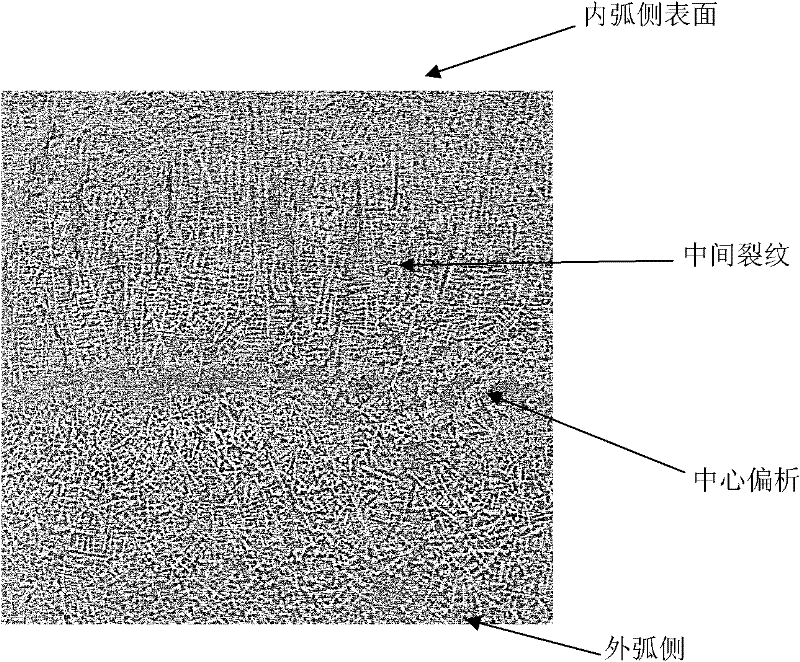

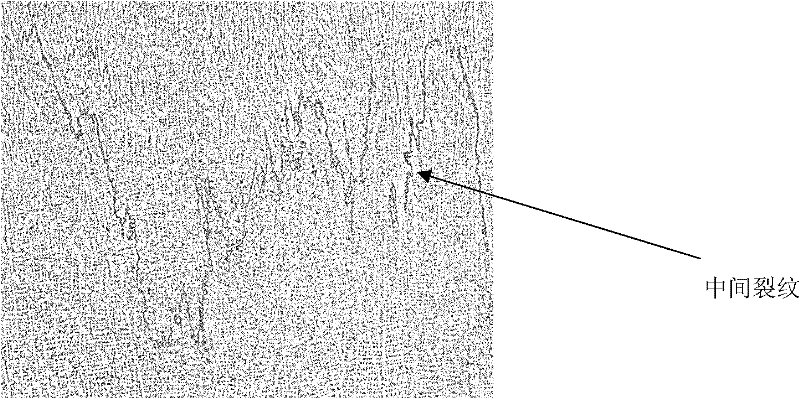

A technology of solidification structure and low-magnification inspection, which is applied in the field of continuous casting of iron and steel, and can solve the problems of unclear observation of solidification structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment, its composition is by mass percentage: copper chloride (CuCl 2 ) 0.28%, magnesium chloride (MgCl 2 ) 0.17%, ferric chloride (FeCl 3 ) 1.60%, hydrochloric acid 1.30%, absolute ethanol 54.75%, and the balance is water. Wherein the mass concentration of hydrochloric acid is 37%.

[0015] The preparation method of the continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment is: the raw material ratio is according to the mass percentage of the reagent composition, that is, copper chloride (CuCl 2 ) 0.28%, magnesium chloride (MgCl 2 ) 0.17%, ferric chloride (FeCl 3 ) 1.60%, hydrochloric acid 1.30%, absolute ethanol 54.75%, and the balance is water. Add water to the container, then add copper chloride, magnesium chloride, ferric chloride and hydrochloric aci...

Embodiment 2

[0019] The continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment, its composition is by mass percentage: copper chloride (CuCl 2 ) 1.09%, magnesium chloride (MgCl 2 ) 0.27%, ferric chloride (FeCl 3 ) 0.56%, hydrochloric acid 1.28%, absolute ethanol 55.80%, and the balance is water. Wherein the mass concentration of hydrochloric acid is 38%.

[0020] The preparation method of the continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment is: the raw material ratio is according to the mass percentage of the reagent composition, that is, copper chloride (CuCl 2 ) 1.09%, magnesium chloride (MgCl 2 ) 0.27%, ferric chloride (FeCl 3 ) 0.56%, hydrochloric acid 1.28%, absolute ethanol 55.80%, and the balance is water. Add water to the container, then add copper chloride, magnesium chloride, ferric chloride and hydrochloric aci...

Embodiment 3

[0024] The continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment, its composition is by mass percentage: copper chloride (CuCl 2 ) 1.0%, magnesium chloride (MgCl 2 ) 0.20%, ferric chloride (FeCl 3 ) 1.30%, hydrochloric acid 1.29%, absolute ethanol 54.70%, and the balance is water. Wherein the mass concentration of hydrochloric acid is 36%.

[0025] The preparation method of the continuous casting slab solidification structure and defect dendrite corrosion low-magnification inspection reagent of this embodiment is: the raw material ratio is according to the mass percentage of the reagent composition, that is, copper chloride (CuCl 2 ) 1.0%, magnesium chloride (MgCl 2 ) 0.20%, ferric chloride (FeCl 3 ) 1.30%, hydrochloric acid 1.29%, absolute ethanol 54.70%, and the balance is water. Add water to the container, then add copper chloride, magnesium chloride, ferric chloride and hydrochloric acid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com