Glue taking waste argil as filler and softener

A waste clay and filler technology, applied in the field of polymer materials, can solve problems such as waste of resources and environmental pollution, and achieve the effects of saving production costs, improving wear resistance, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 natural rubber compound;

Embodiment 2

[0027] Embodiment 2 Styrene-butadiene rubber compound.

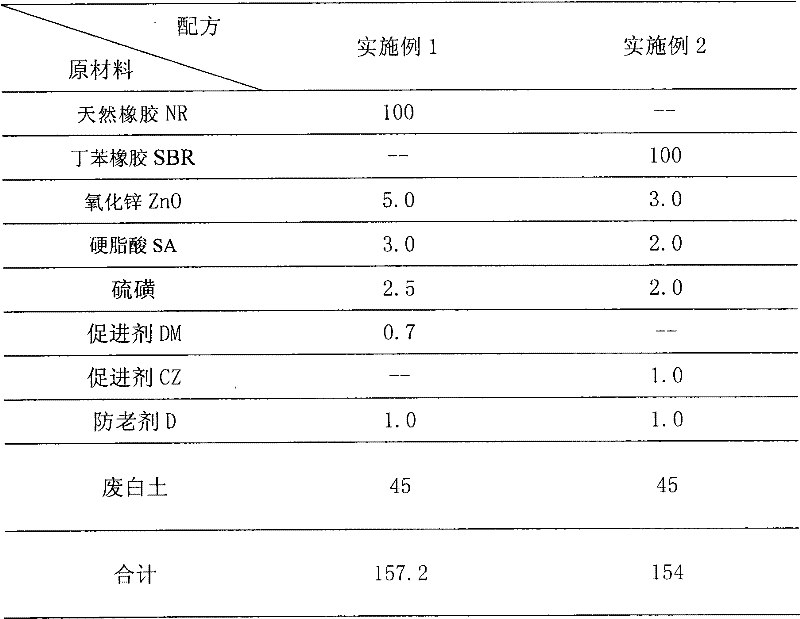

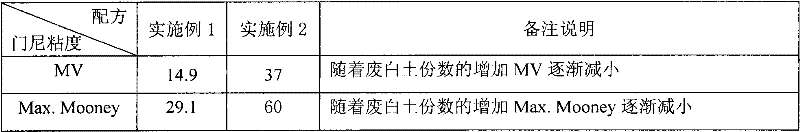

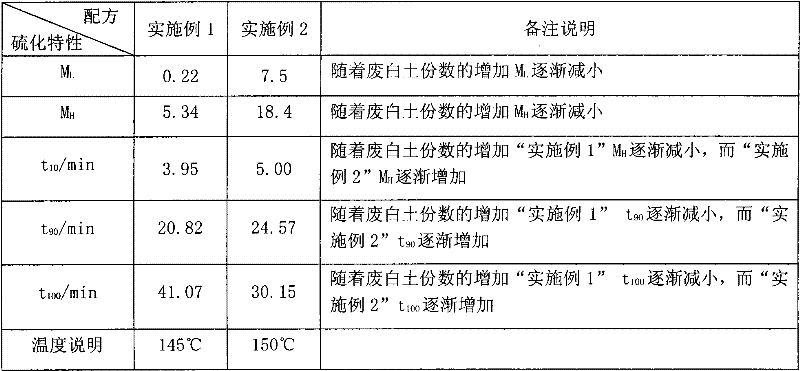

[0028] 1. See Table 1 for the raw material formulations of the above two rubber materials.

[0029] Table 1

[0030]

[0031] Second, the preparation method of rubber

[0032] The preparation method of embodiment 1

[0033] 1) Drying of the waste clay: drying the waste clay at 70-100°C for 24-96 hours to make the water content ≤ 3% and the oil content 28-30%, and set aside;

[0034] 2) Ingredients: Weigh natural rubber or styrene-butadiene rubber, zinc oxide, stearic acid, anti-aging agent D, sulfur, accelerator, and various raw materials of waste clay according to proportion and mass fraction;

[0035] 3) Raw rubber mastication: natural rubber or styrene-butadiene rubber is used for thin-pass mastication of open mill: roll distance 0.5-1.0mm, roll temperature 45°C-50°C, thin pass times 8-10 times;

[0036] 4) Mixing of masterbatch rubber: mix zinc oxide, stearic acid, anti-aging agent D and plasticized raw rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com