Pneumatic linear driven chip picking and turning device

A technology of linear drive and turning device, which is applied in the direction of electrical components, transportation and packaging, furnaces, etc., can solve problems such as difficulties, complex structures, and inability to meet high-efficiency requirements, and achieve the effect of safe chip picking and high turning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described now in conjunction with the preferred implementation examples of the accompanying drawings.

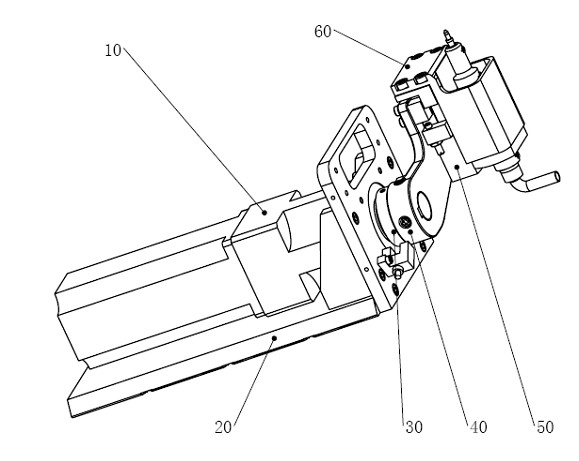

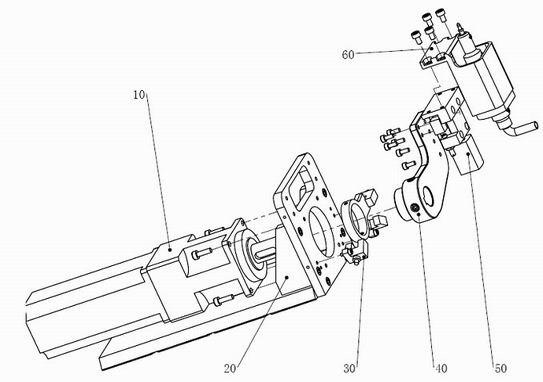

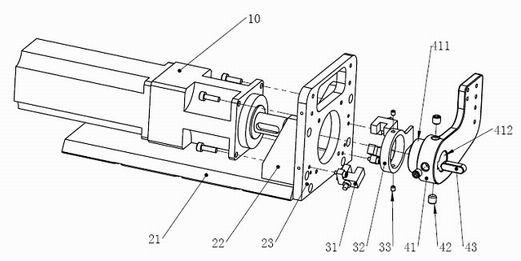

[0019] see figure 1 and figure 2 , The preferred embodiment of the present invention mainly includes a rotary drive assembly 10 , a support assembly 20 , a sensor assembly 30 , a turning arm assembly 40 , a linear drive assembly 50 , and a chip suction assembly 60 . The support assembly 20 can install and fix the entire device in the chip flip-chip bonding equipment, and the rotation assembly 10 drives the flip arm assembly 40, the linear drive assembly 50 and the chip suction assembly 60 to rotate to provide power for flip chips. The linear drive assembly 50 pushes the chip pick-up assembly 60 to achieve linear motion, and can complete the gap between the suction nozzle and the wafer chip by fine-tuning the stroke, so as to ensure effective pick-up of the chip. The chip pick-up component 60 includes an elastic element, which has the functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com