Roller sprocket plate garbage feeder

A feeder and sprocket technology, applied in the field of roller sprocket plate type garbage feeder, can solve the problems of slow running speed, no good hardness, danger, etc., and achieve the effect of slow running speed, good hardness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

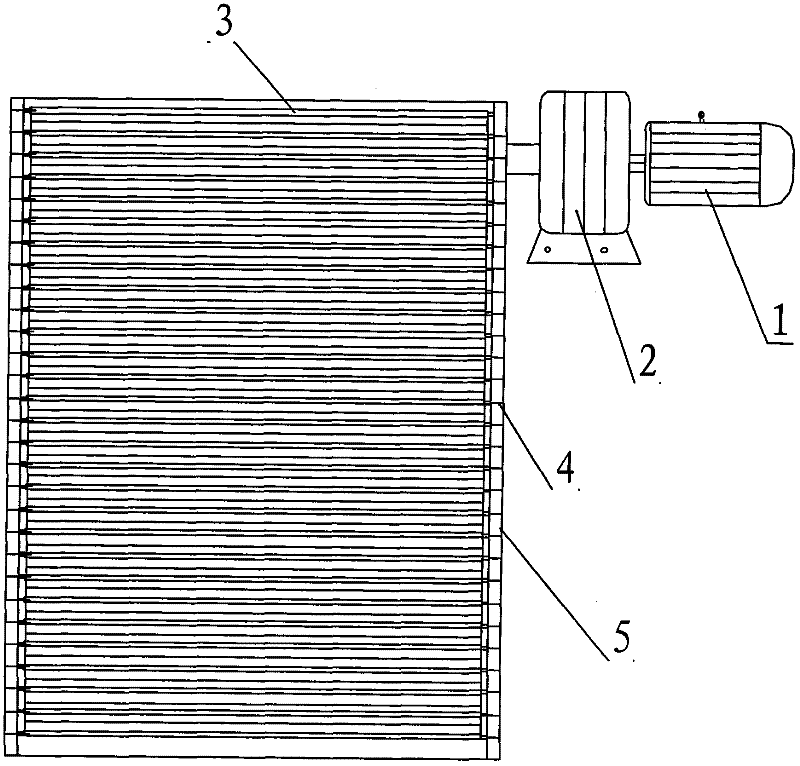

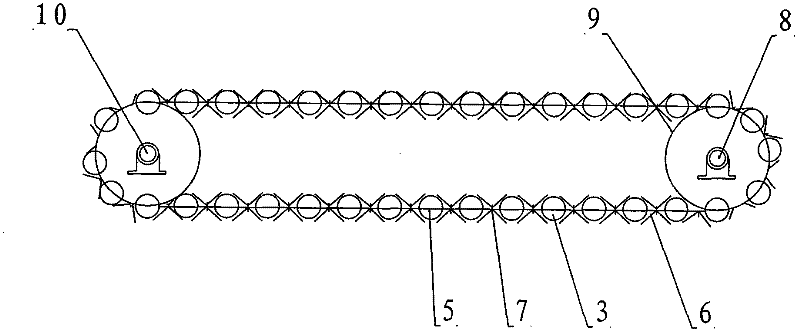

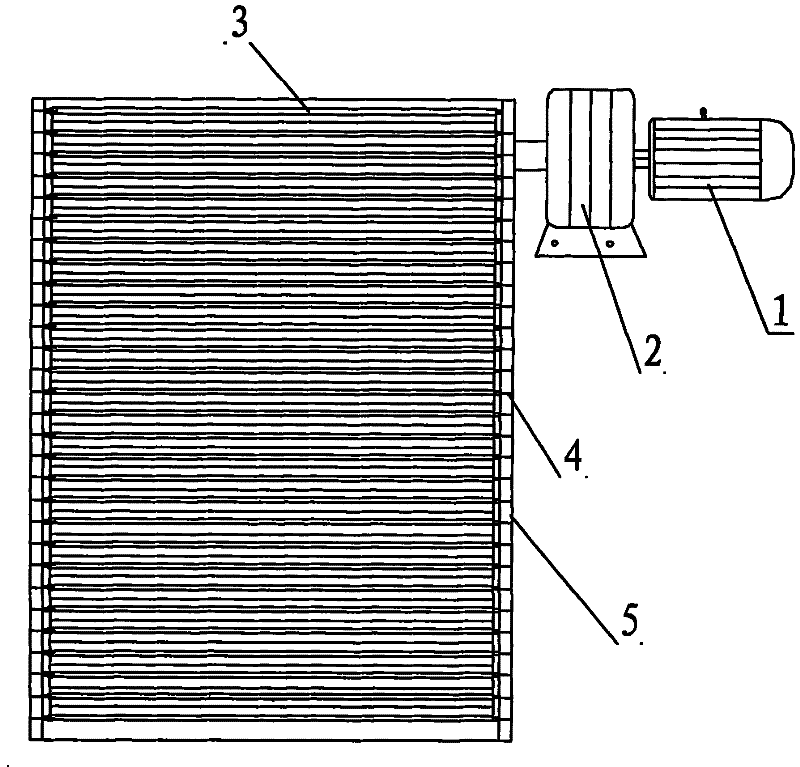

[0009] Referring to the drawings, the present invention includes a motor 1, a reducer 2, a driving axle 8, a driven axle 10, and a roller 3, and sprockets 9 are installed at both ends of the driving axle 8 and the driven axle 10. The driving axle 8 and A chain 5 is installed between the sprockets of the driven wheel shaft 10; the rollers 3 are arranged side by side, and the shaft heads at both ends of each roller correspond to the shaft 4 of a chain, and are connected with the corresponding chain shaft as a whole, so that the rollers The shaft 3 forms a closed ring, and each two adjacent rollers are provided with angle steels 6 with opposite top angles, and the opposite angle steels 6 are connected by bolts 7 .

[0010] In application, the motor is turned on, the motor drives the reducer to run at low speed, the reducer drives the driving axle and the sprocket to rotate, the sprocket drives the chain, the roller moves with the chain, and the roller and the angle steel between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com