Novel resin grinding wheel forming machine

A resin grinding wheel and molding machine technology, which is used in household components, applications, household appliances, etc., can solve the problems of difficulty in obtaining resin grinding wheel process parameters, large number of production line equipment, and difficulty in process preparation, achieving a small footprint and simplification Production process, the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

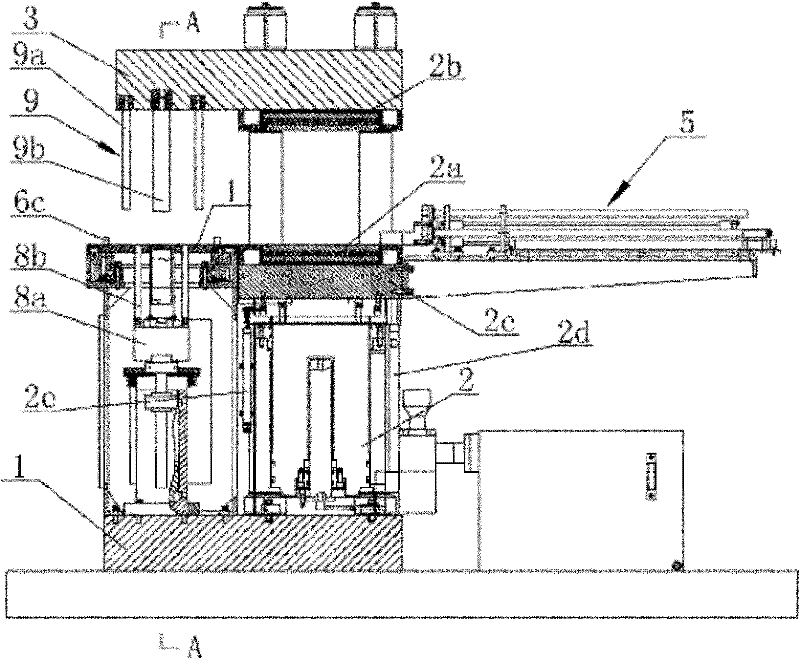

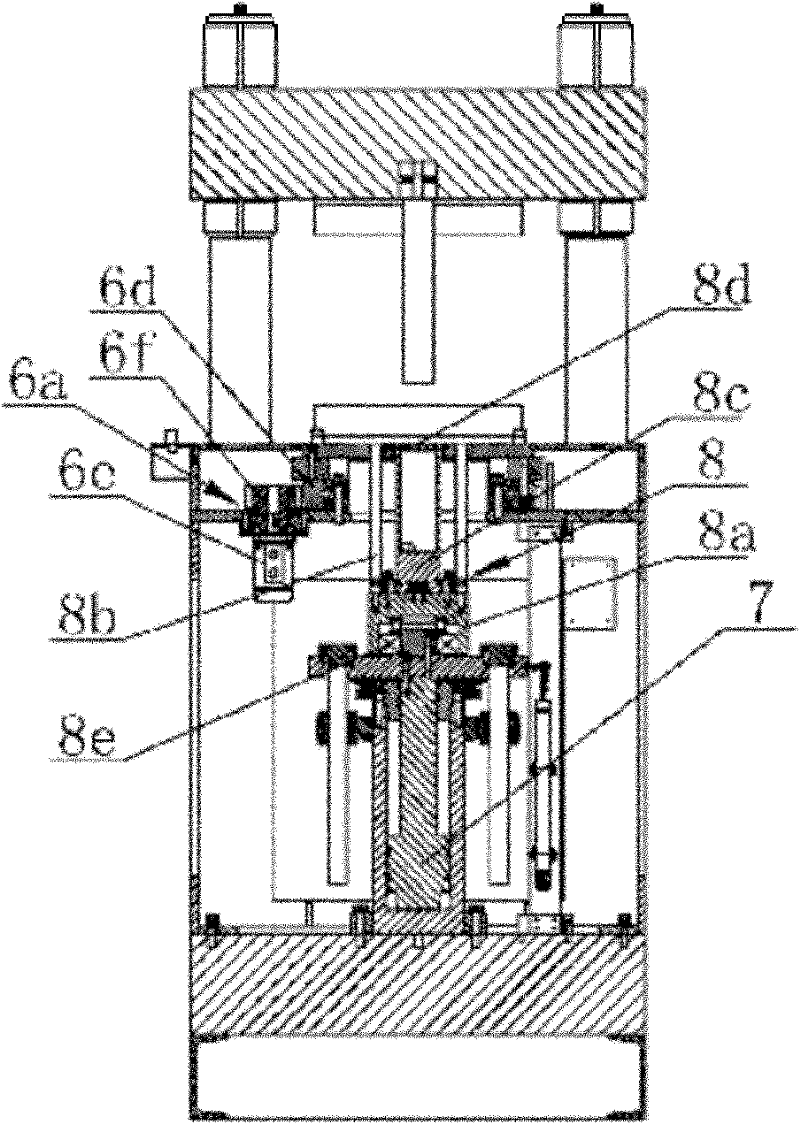

[0032] refer to Figure 1 to Figure 4As shown, a novel resin grinding wheel forming machine of the present invention comprises a frame 1, on which a clamping oil cylinder 2 is arranged; The parallel mold clamping grating ruler 2d is provided with a fixed limit block 2e on the frame 1 on the other side of the mold clamping cylinder 2, and the fixed limit block 2e is used to limit the moving distance of the mold clamping cylinder 2. The upper end of the power output shaft is provided with a mobile workbench 2c, a lower hot plate 2a is arranged on the mobile workbench 2c, a positioning block 3 is provided on the frame 1 above the lower heat press plate 2a, and a positioning block 3 is provided at the bottom of the positioning block 3 Corresponding upper hot pressing plate 2b with lower hot pressing plate 2a; Upper and lower hot pressing plate 2b, be provided with emery wheel forming die 4 between 2a, in the present embodiment, emery wheel forming die 4 is formed die ring 4a, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com