Combined lens processing mold

A mold processing and combined technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of high material cost, inconvenient installation and storage of lens molds, etc., to overcome uneven line speed, improve processing accuracy, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

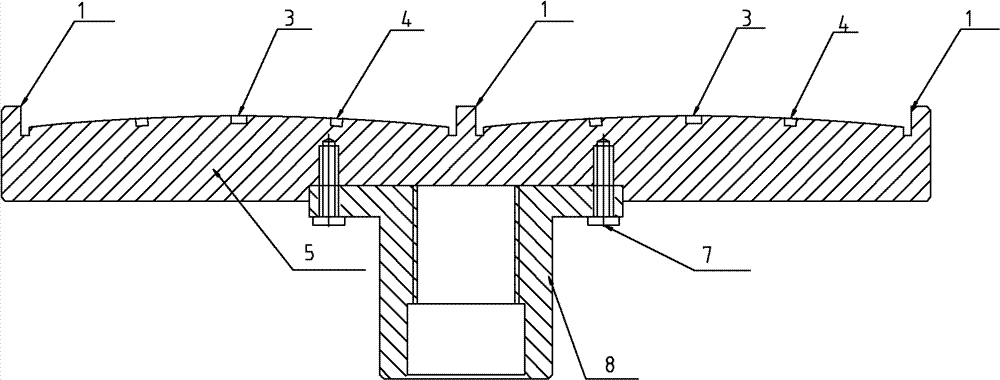

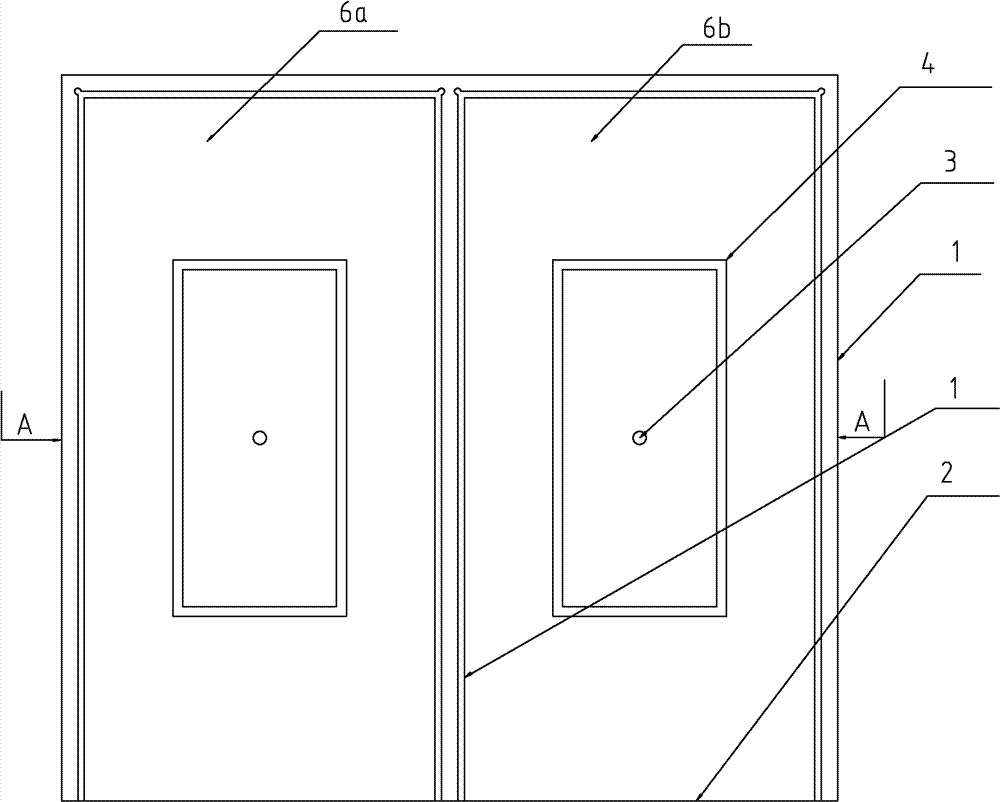

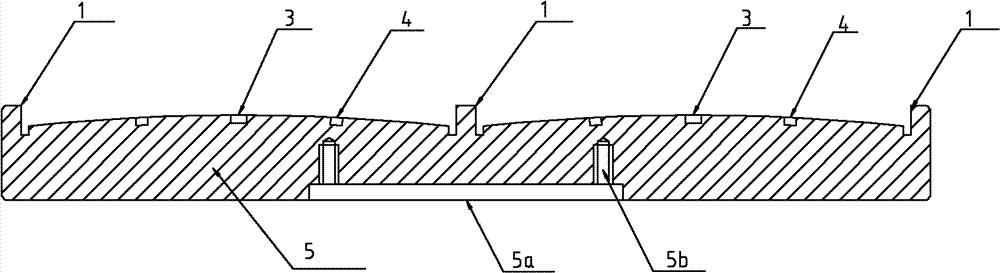

[0030] combine figure 1 , 2 , 3, 5 and 6.

[0031] figure 1 It is a schematic diagram of the combined section structure of the mold in this example; figure 2 It is a schematic diagram of the planar structure of the mold base in this example; image 3 It is a schematic diagram of the cross-sectional structure of the mold matrix in this example; Figure 5 is a schematic diagram of the cross-sectional structure of the connector in this example; Figure 6 It is a schematic diagram of the planar structure of the connecting body connecting the connecting head and the mold base in this example.

[0032] as the picture shows. The mold includes a mold base 5 and a mold connecting head 8, the mold base 5 and the mold connecting head 8 can be disassembled and combined, and there are two juxtaposed lens bonding seats 6a and 6b on the mold base 5. There are protrusions 1 in three directions on the outer edge of each lens bonding seat, and an opening 2 is formed without protrusions ...

Embodiment 2

[0036] combine figure 1 , 2 , 4, 5 and 6.

[0037] Same as Embodiment 1, only the surface shape of the bonding disk used for processing and grinding is different in this embodiment. The surface shape of the processed lens is different. In fact, the mold matrix 5 can be replaced during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com