Numerical control gear hobbing processing control device and processing control method for face gear

A control device, face gear technology, applied in the direction of digital control, electrical program control, belt/chain/gear, etc., can solve problems such as lack, and achieve the effect of improving processing accuracy and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

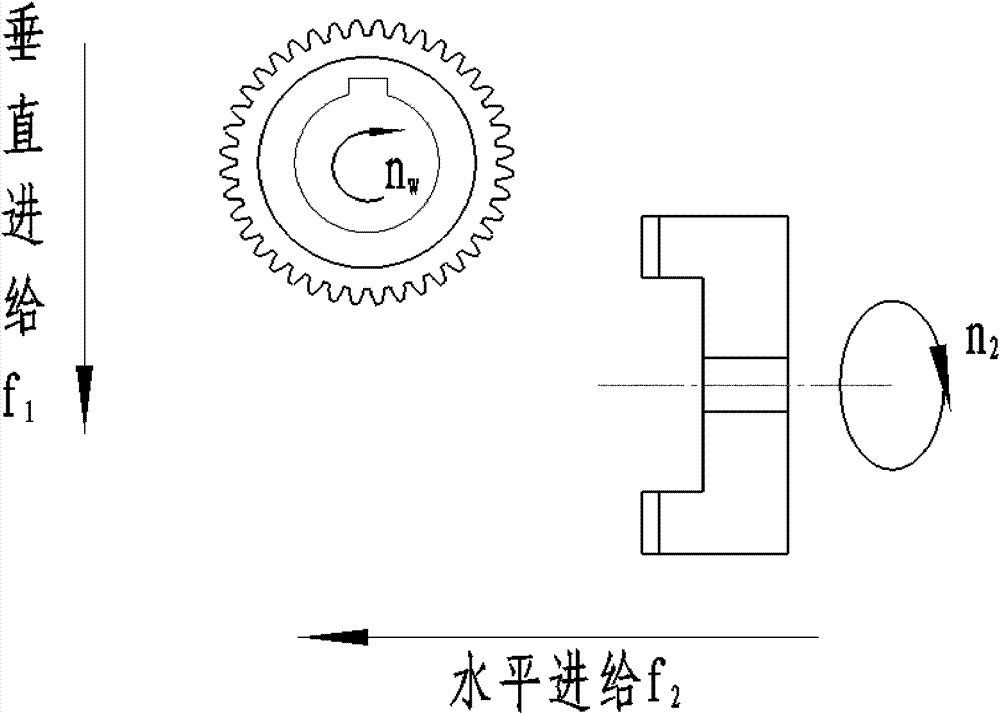

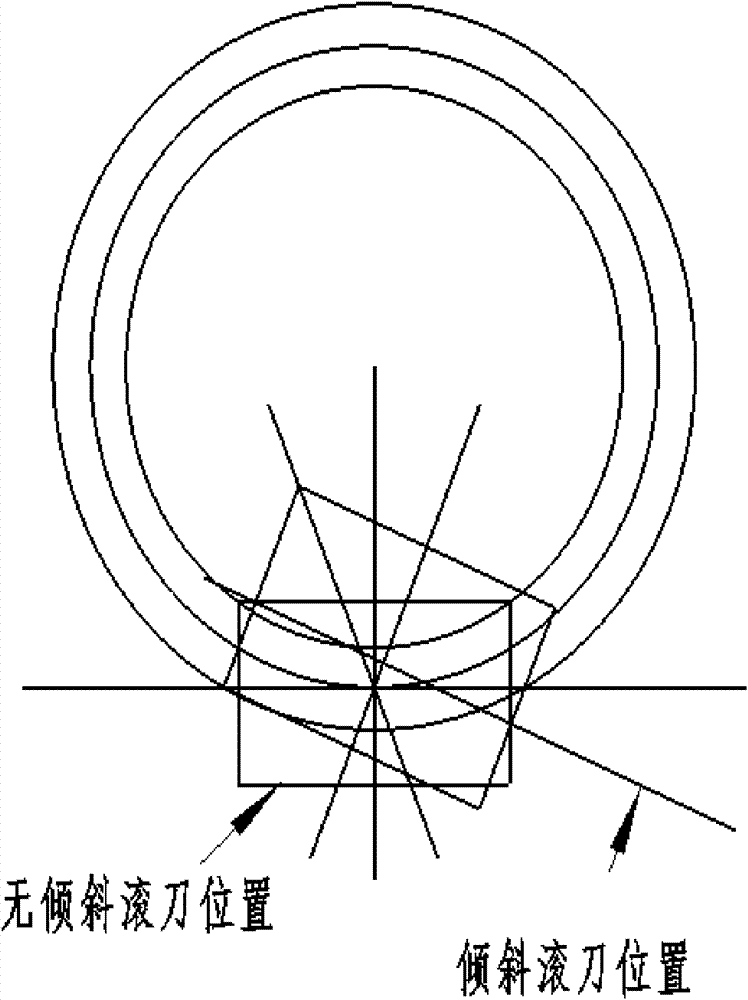

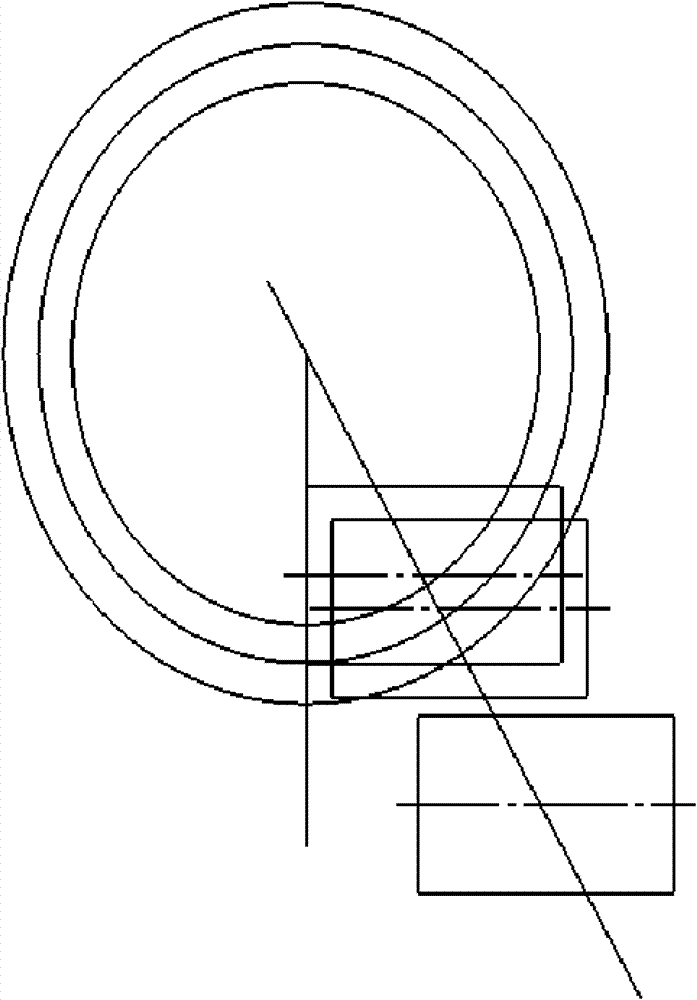

[0028] Such as figure 1 As shown, according to the hobbing principle of the face gear, the multi-axis linkage machine tool must be able to realize the four movements of the main movement, the sub-tooth movement, the vertical feed movement and the horizontal feed movement of the face gear CNC hobbing. At the same time, due to the existence of the helix angle of the hob, the axis of the hob must rotate around the section of the face gear by an angle of the helix angle, such as figure 2 As shown, but due to the limitation of the machine tool structure, the spindle tool cannot complete the rotation of a helix angle, which brings inconvenience to the processing. To solve this problem, the tool is not moved, and the workpiece is offset by a distance relative to the original position. Equivalently complete the rotation of the helix angle of the face gear hob, such as image 3 shown. no w Represents the speed of the hob, n 2 Represents the rotational speed of the workpiece, f 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com