Flow type precise automatic liquid supplementing device

An automatic rehydration device and precise technology, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of great influence of human factors on the rehydration accuracy and inaccurate rehydration amount, etc., and achieve the concentration of the solution. The effect of maintaining stability, ensuring cleaning quality and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

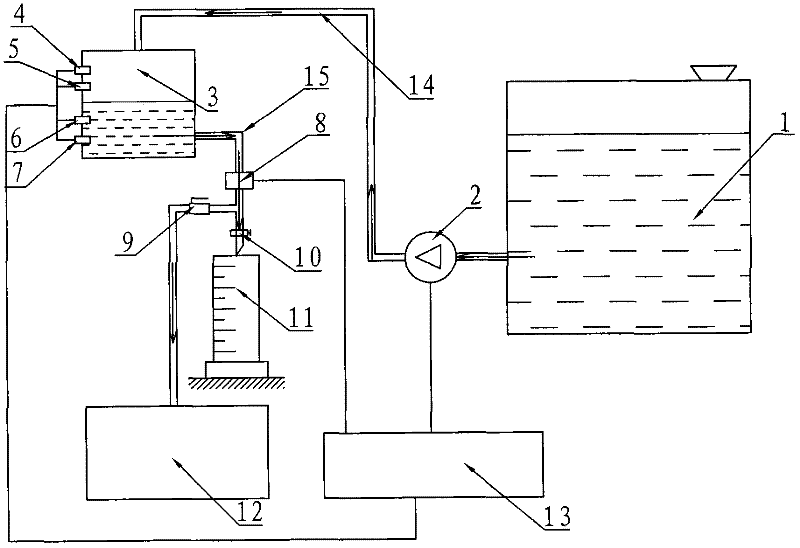

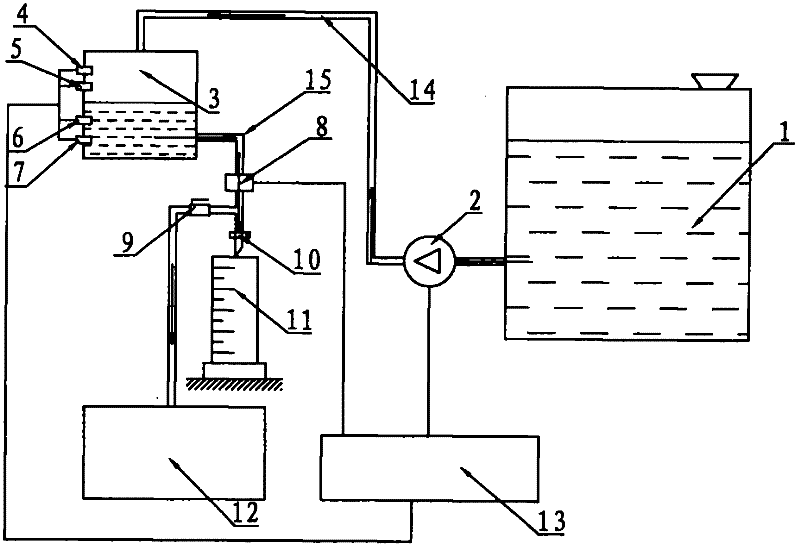

[0010] The flow-type precise automatic replenishment device includes a liquid storage tank 1, a mechanical replenishment pump 2, a constant pressure tank 3, an upper alarm sensor 4, an upper liquid level sensor 5, a lower liquid level sensor 6, a lower alarm sensor 7, Electromagnetic reversing valve 8, manual replenishment valve 9, manual calibration valve 10, measuring cup 11, cleaning tank 12 and control system 13, the liquid storage tank 1 is set next to the automatic silicon wafer cleaning machine, and the liquid storage tank 1 is stored for replenishment solution, a liquid filling opening is provided on the top of the liquid storage tank 1 for operators to add solution to it, the constant pressure tank 3 and the liquid storage tank 1 are connected by an acid and alkali resistant infusion tube 14, and the mechanical infusion pump 2 is set at Between the constant pressure tank 3 and the liquid storage tank 1, an upper alarm sensor 4, an upper liquid level sensor 5, a lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com