Impurity removal system for mesona chinensis liquid

A liquid, fairy grass technology, applied in solid solvent extraction, separation of sediments by centrifugal force, etc., can solve the problems of inability to meet the supply, low screen flow, affecting production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

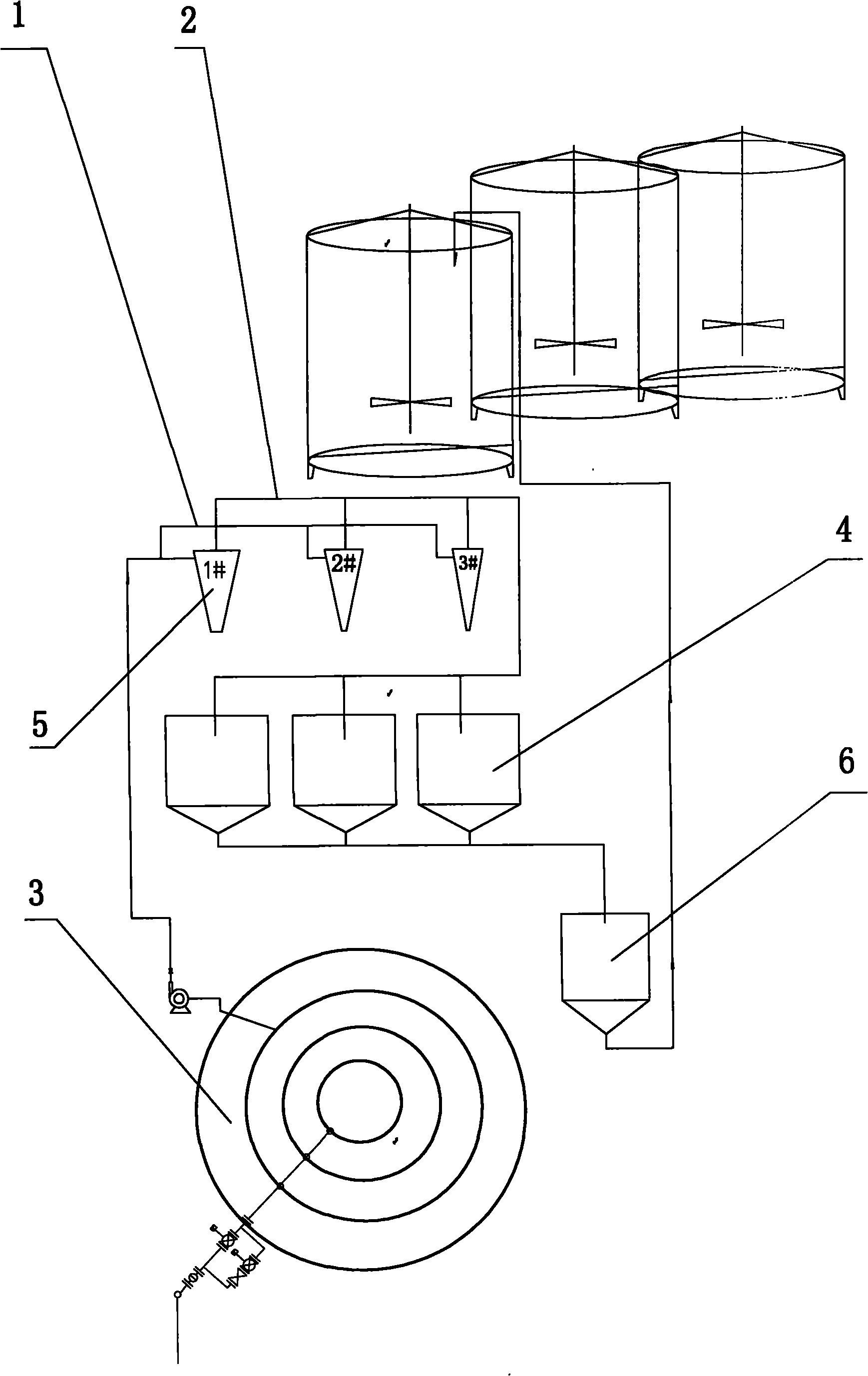

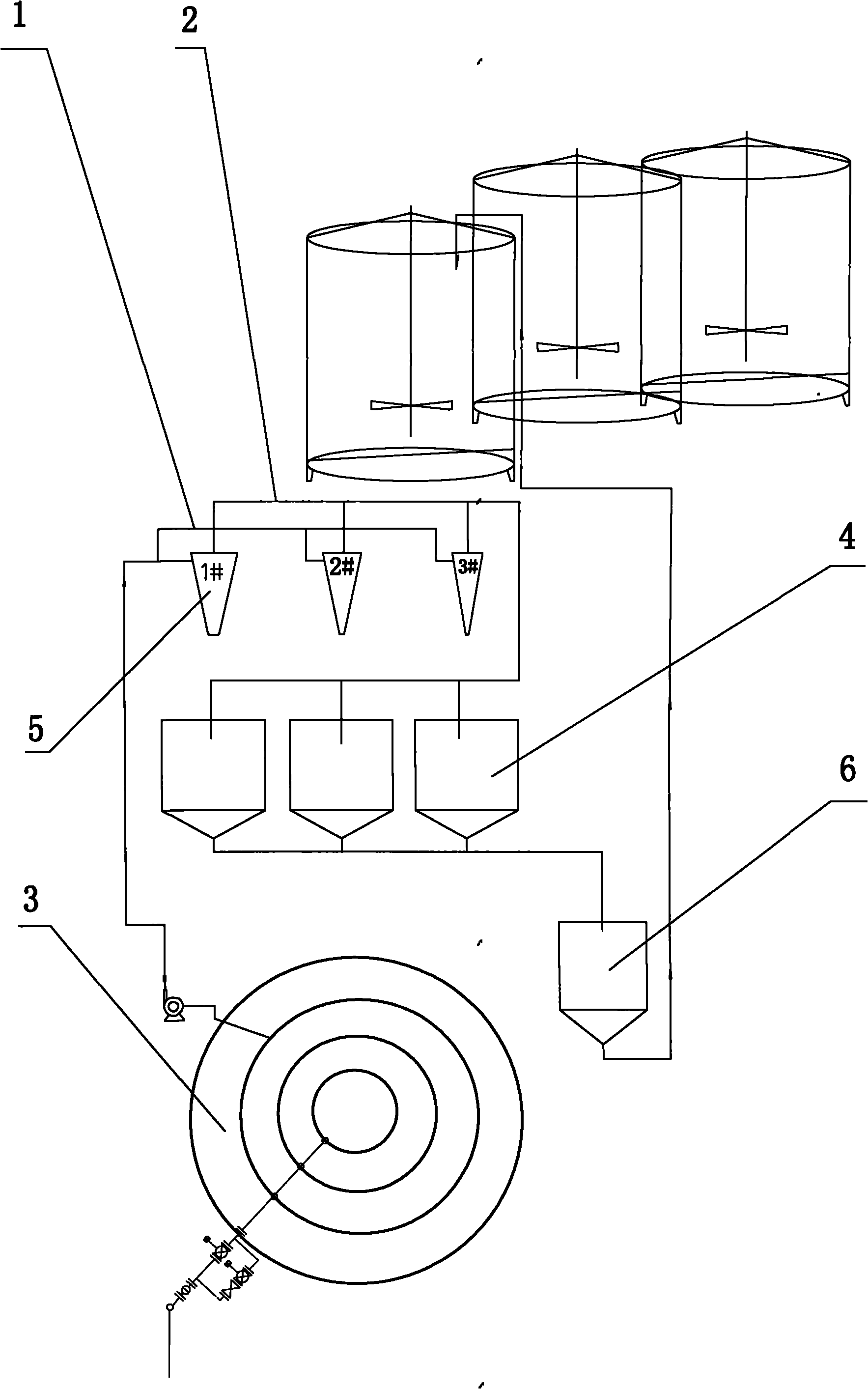

[0016] The impurity removal system for liquid jelly of the present invention is arranged between the boiling extraction process and the concentration process, and is a combination of No. 1, No. 2, and No. 3 three inverted conical cylinders 5. The volume of each conical cylinder 5 is in the order of numbering gradually decrease, as figure 1 shown.

[0017] The specific structure of the conical cylinder 5: the bottom of the conical cylinder 5 has an opening at the end of the cone for removing impurities, the upper wall of the conical cylinder 5 is provided with a liquid inlet, and the top of the conical cylinder 5 is provided with a liquid outlet.

[0018] The connection between each conical cylinder 5: the liquid inlet of each conical cylinder 5 is connected to the liquid inlet pipe tangentially, the liquid outlet of each conical cylinder 5 is connected to the liquid outlet pipe upward, and each liquid inlet pipe is connected in parallel to the inlet pipe. Liquid main pipe 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com