Method for comprehensively measuring reflectivity

A comprehensive measurement and reflectivity technology, which is applied in the direction of reflective surface testing, scattering characteristic measurement, optical performance testing, etc., can solve the problems of inaccurate measurement and inaccurate measurement of reflectivity, etc., and achieve the effect of simple and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

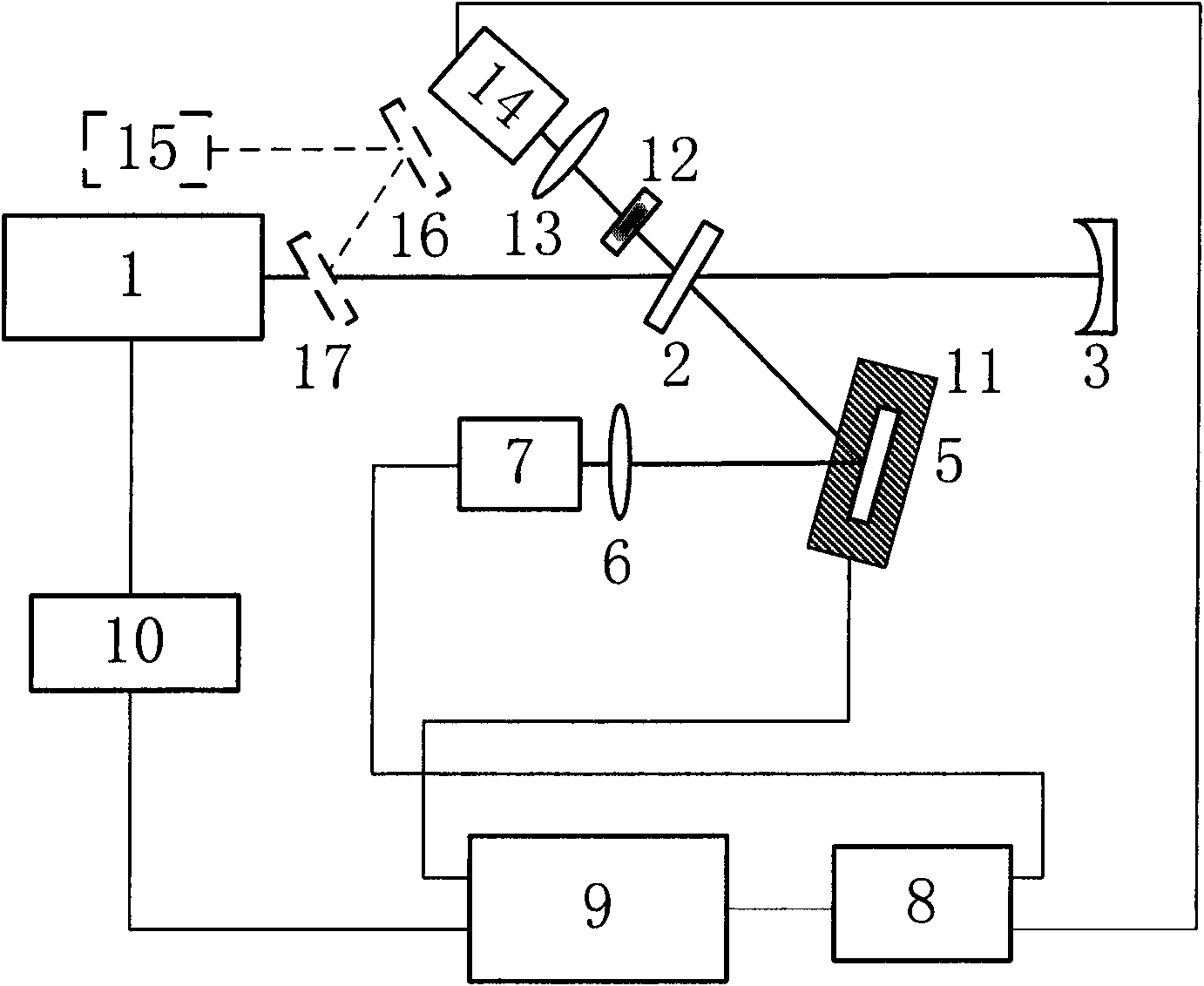

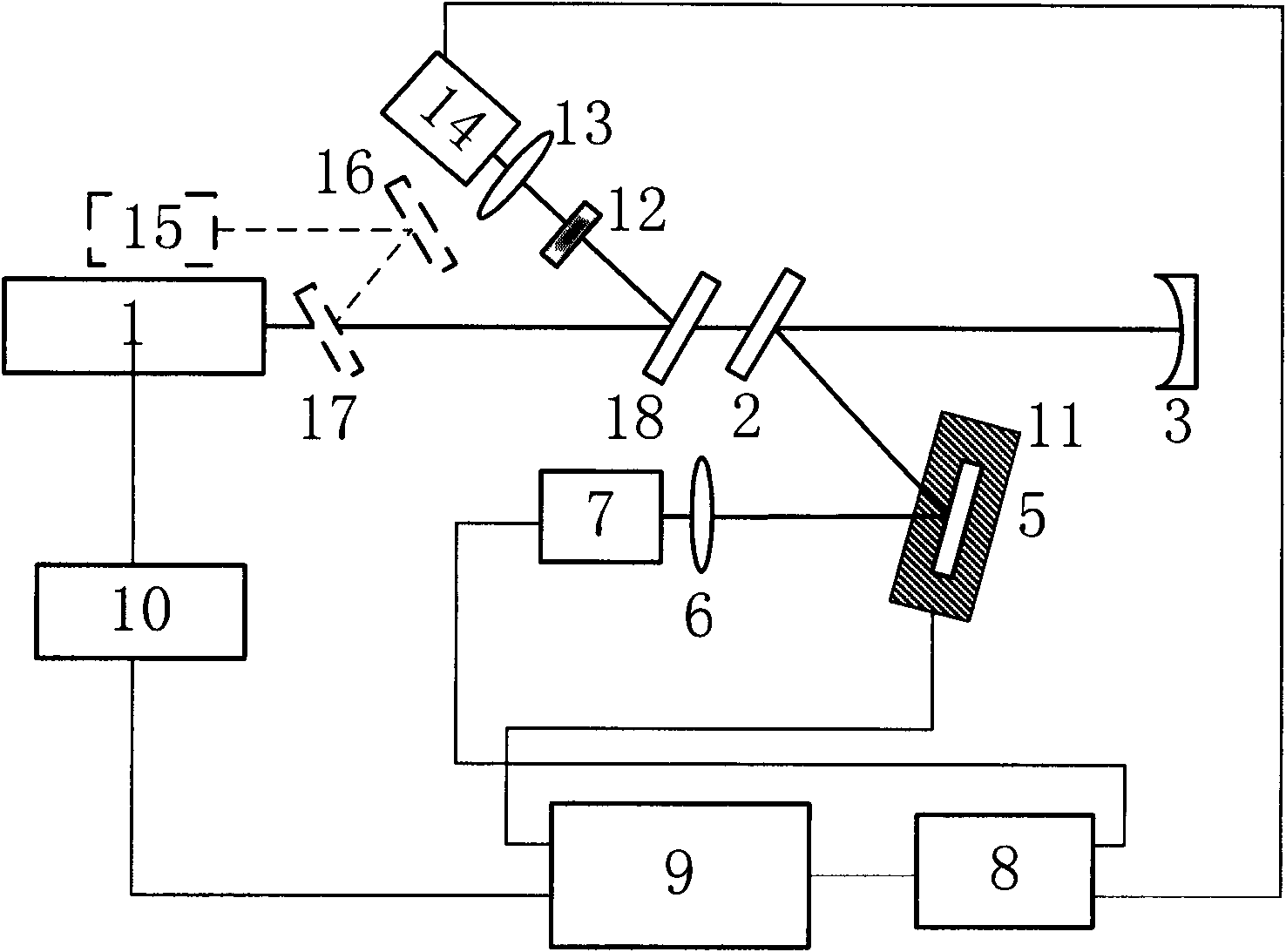

[0028] Attached below figure 1 The system described describes an integrated reflectance measurement device of the present invention. figure 1 Middle: 1 is the light source, 2 is the plane high reflection mirror, 3 and 4 are the plano-concave high reflection mirror, 5 is the optical element to be tested, 6 and 13 are the focusing lens, 7 and 14 are the photodetector, 8 is the data acquisition card , 9 is a computer, 10 is a function card, 11 is a two-dimensional displacement platform, 12 is a variable attenuator, 15 is a visible auxiliary light source, 16 is a reflector, 17 is a beam splitter, and the plano-concave high reflector 4 is a flat The concave high reflection output cavity mirror, the thick line in the figure is the optical path, and the thin line is the connecting line.

[0029] The light source 1 is a continuous semiconductor laser, the laser adopts square wave modulation output, and the square wave is generated by the function generation card 10 controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com