Device for automatically feeding and metering flour

A technology of measuring device and automatic powder supply, applied in measuring device, automatic feeding/discharging weighing equipment, weighing and other directions, it can solve the problems of low measuring accuracy, low level of production automation, large loss of flour, etc. Accurate measurement, simple and reliable structure, accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

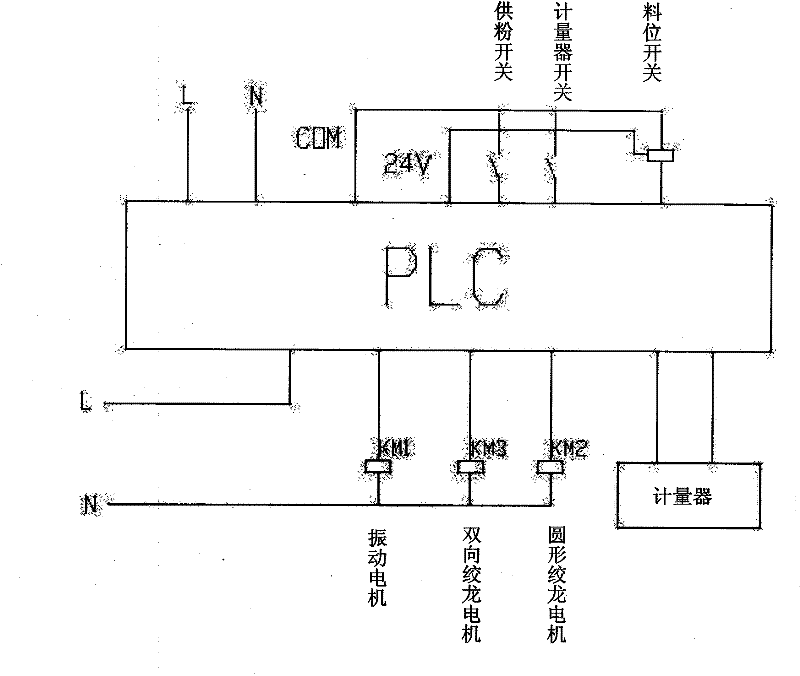

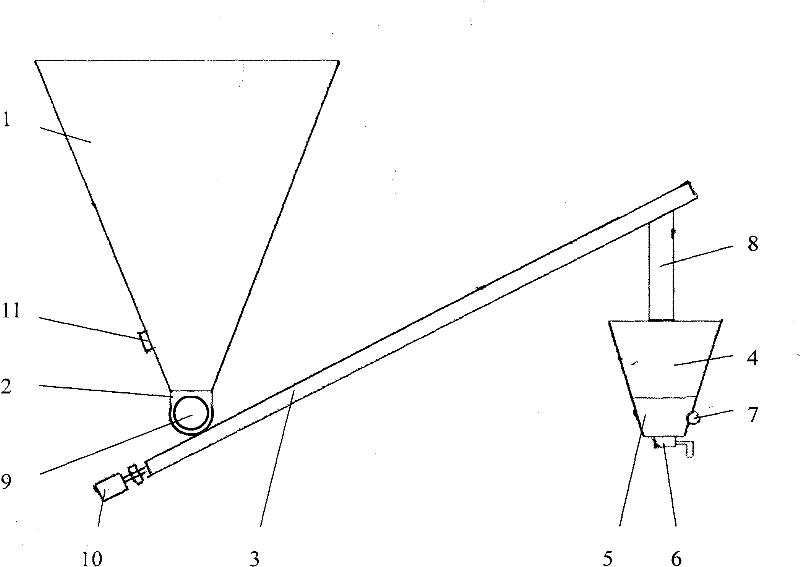

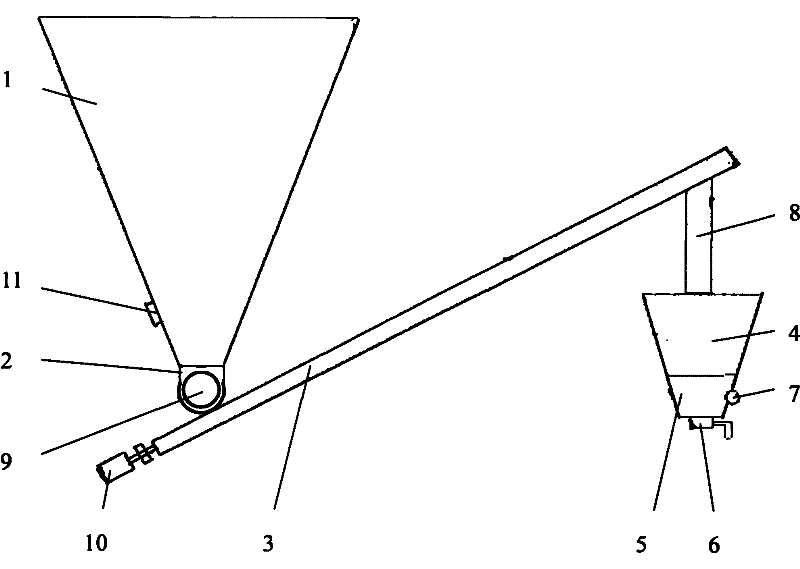

[0012] Such as figure 1 figure 2 As shown, the flour automatic powder supply metering device is composed of a flour bin 1, a two-way auger 2, a circular dragon 3, a measuring device 4, a buffer bucket 5, a surface outlet 6 and a material level device 7. The bottom of the flour bin 1 There is a two-way auger 2 at the end, the two-way auger 2 is connected with the round dragon 3, the round dragon 3 is connected with the meter 4 through the feeding pipe 8, the buffer bucket 5 is arranged under the meter 4, and the buffer bucket 5 is provided with The surface outlet 6 is set, the buffer bucket 5 is provided with a material level device 7; the two-way auger 2 is connected with the two-way auger motor 9, the round dragon 3 is connected with the round dragon motor 10, and the flour bin 1 is provided with a vibration motor 11; Device 4, two-way auger motor 9, circular dragon motor 10, vibration motor 11 are connected with programmable logic controller (PLC) through circuit, and prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com