High-efficiency air blocking-free honeycomb cellular type heat exchanger

A technology of honeycomb holes and heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchanger sealing devices, etc., can solve problems such as poor sealing effect, pressure resistance, and low heat exchange efficiency, and achieve It is convenient to seal and disassemble for cleaning, prevent internal and external leakage of fluid, and improve the effect of heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

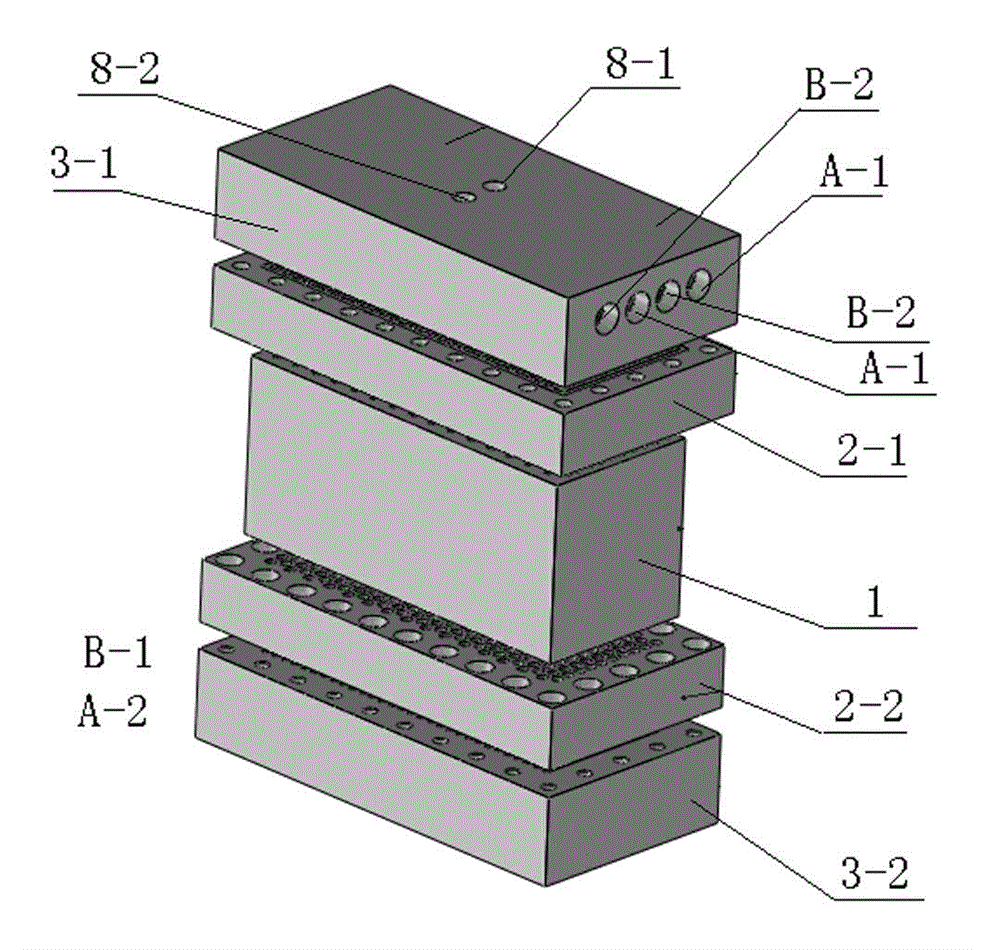

[0014] Embodiment: refer to attached figure 1 :

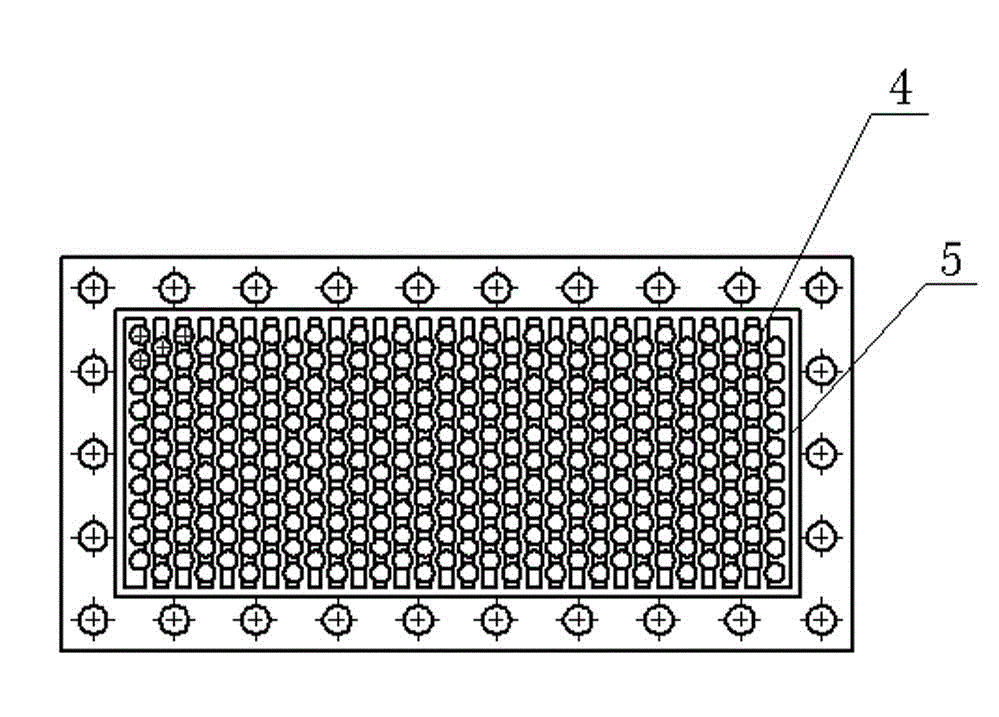

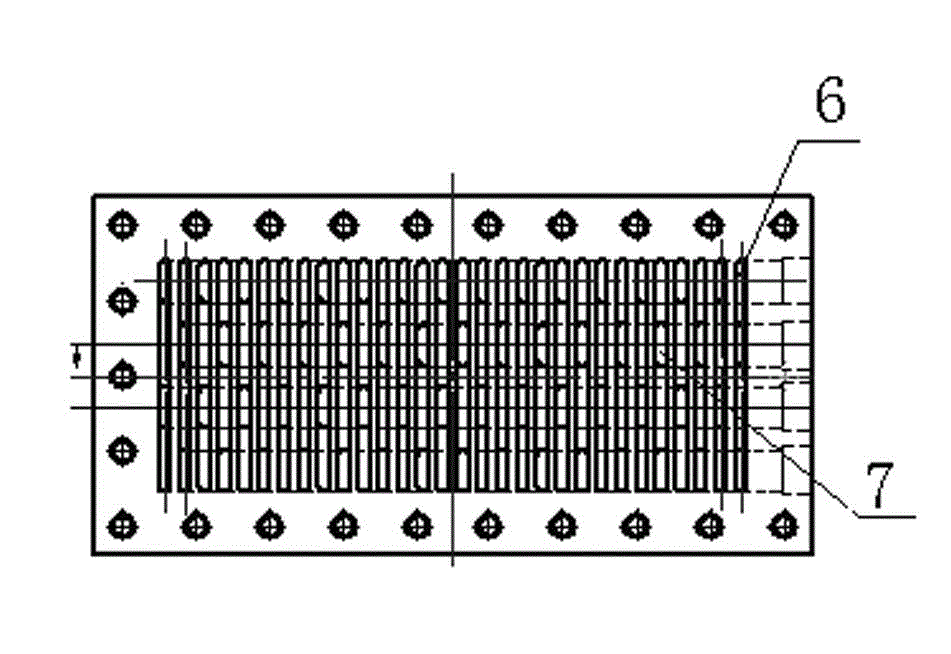

[0015] The heat exchange element in the heat exchange unit body 1 of this embodiment is a honeycomb structure formed of honeycomb holes that are integrally formed from metal, and the wall thickness of the honeycomb holes is 0.3-7mm. On the outer sides of the two end faces 2-1 and 2-2 of the heat exchange unit body are upper and lower cold and hot fluid dividers 3-1 and 3-2, and the cold and hot fluid dividers are integrated with the diversion groove. In this embodiment, the inlet and outlet of the cold fluid and the inlet and outlet of the hot fluid arranged at both ends of the hot and cold fluid divider are two groups; the hot fluid enters from the two inlets A-1 at the right end of the upper divider 3-1, The two outlets A-2 on the back of the lower splitter on the left flow out; the cold fluid enters from the two inlets B-1 on the back of the left end of the lower splitter, and flows out from the two outlets B-2 on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com