Electrodeionization method and electrodeionization device with enhanced scale prevention effect

A technology of electrodeionization and electrode plates, which is applied in the field of water desalination, can solve the problems of difficult water intake requirements for produced water quality, lack of renovation conditions for the site, and insufficient share of pure water technology, and achieve relaxation of water hardness restrictions, Good sealing and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

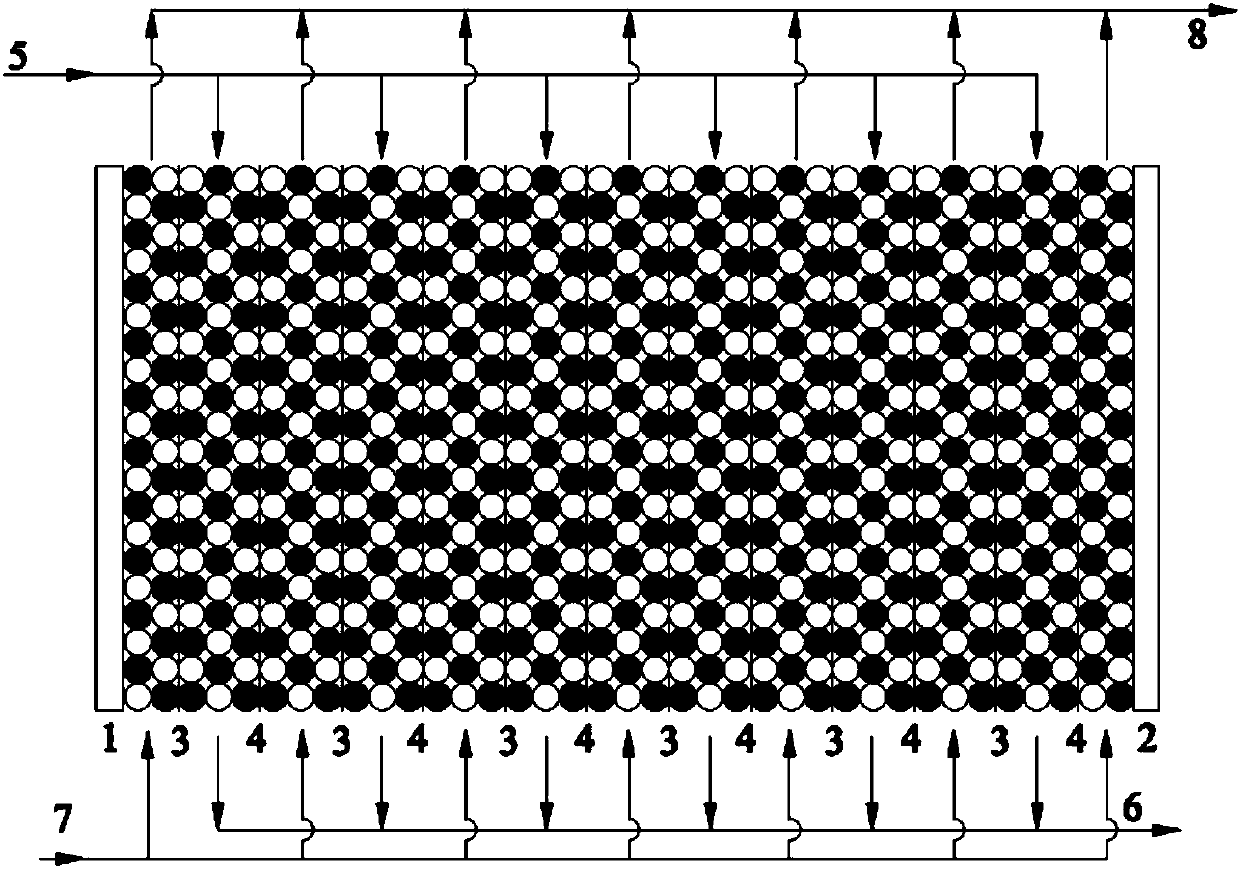

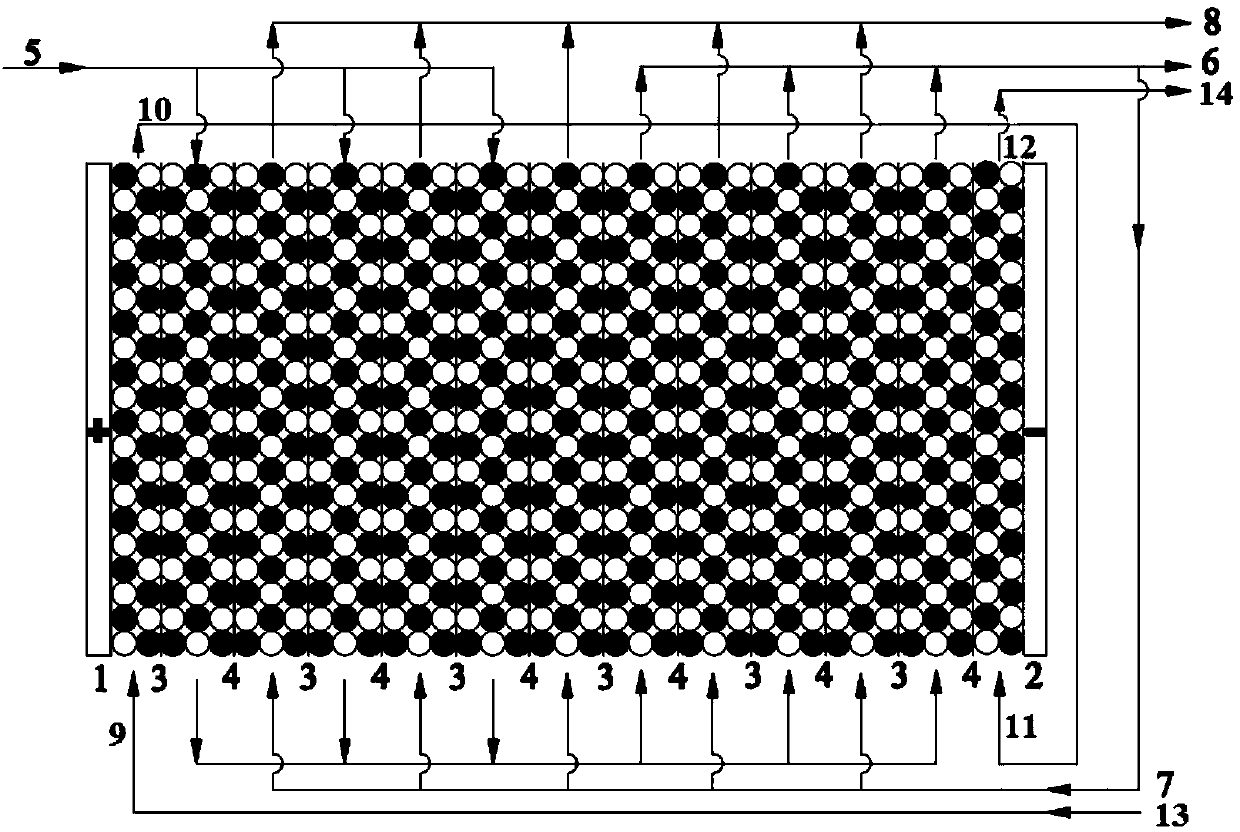

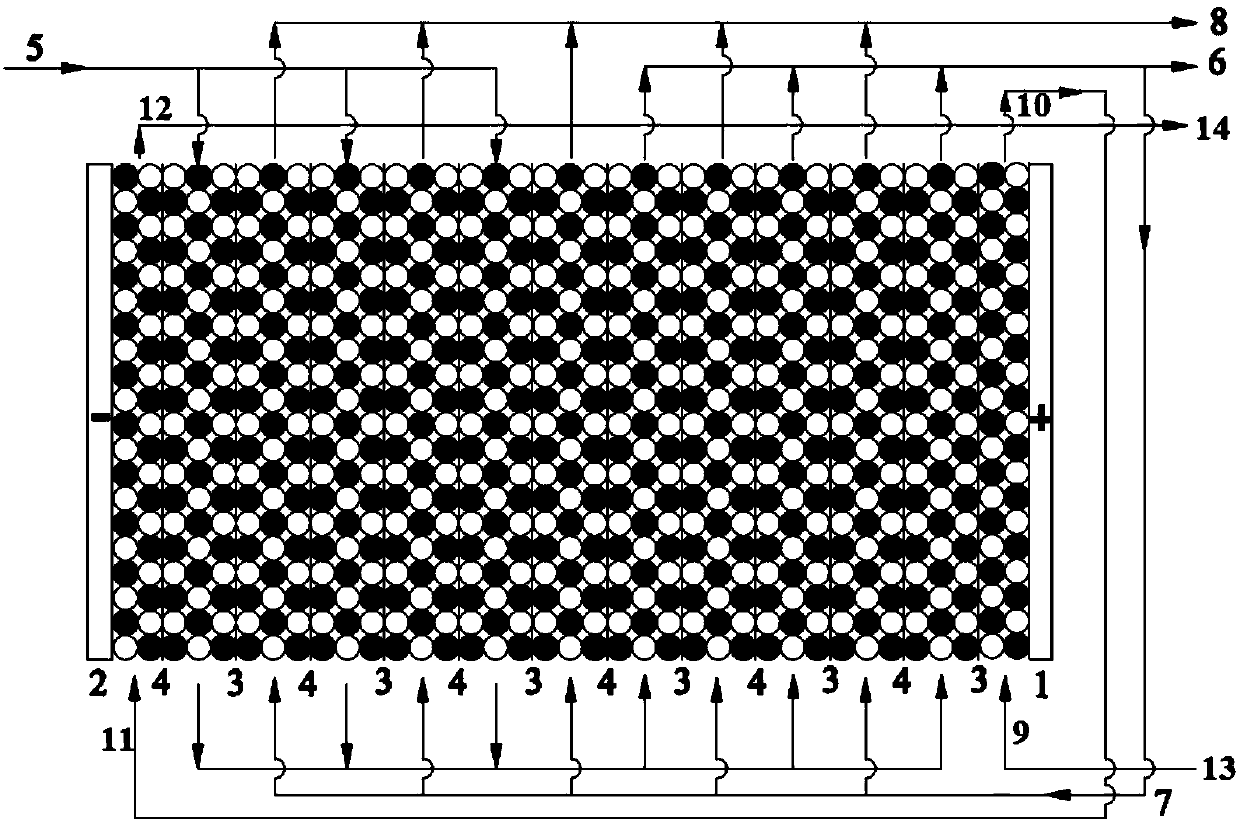

[0052] In this example, the EDI device adopts the structure of one stage and two stages for fresh water, and one stage and one stage for concentrated water, including 10 basic working units. The size of the separator in the desalination chamber is 668mm×330mm×10mm, the size of the separator in the concentrated water flow and the electrode chamber is 668mm×330mm×4.9mm, and the effective membrane area of each separator is 888cm 2 . The basic working unit of the EDI membrane stack, that is, the number of membrane pairs is 10. The ion-exchange membrane used by EDI is a special-purpose heterogeneous ion-exchange membrane for EDI, produced by Hangzhou Er Environmental Protection Technology Co., Ltd.; the ion-exchange resin is Marathon cation-exchange resin (Na + type) and Marathon anion exchange resin (Cl - type). The volume ratio of anion and cation resins in all compartments is 1:1.

[0053] Ca in raw water tank 23 2+ The ion concentration is 1.71mg / L, mg 2+ The ion concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com