A preparation method of antifouling and chlorine-resistant aromatic polyamide composite film

A technology of aromatic polyamide and composite membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve marine biological pollution and other problems, and achieve high desalination rate, high stability of resistance to chlorine and oxygen, and stable performance lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

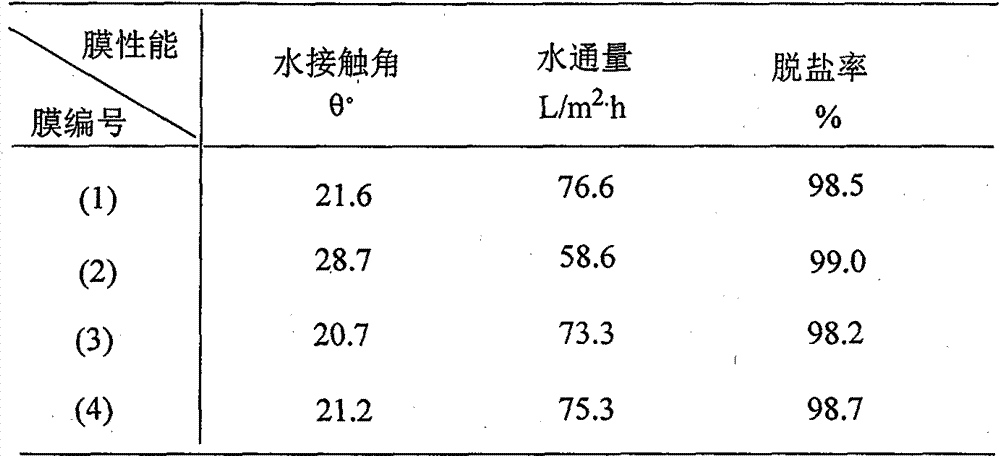

Embodiment 1

[0031] Example 1 Preparation of anti-fouling and chlorine-resistant aromatic polyamide composite membrane (1)

[0032] Step 1 Preparation of Aramid Composite Membranes Containing Primary Amino Groups on the Surface

[0033]According to the methods and operating steps disclosed in Journal of Membrane Science 428 (2013) 403-409 or Journal of Membrane Science 457 (2014) 88-97 or CN103349922, on the surface of the 10*10cm square microporous polysulfone support membrane, pass through the Interfacial polymerization of phenylenediamine and trimesoyl chloride to prepare a nascent aromatic polyamide composite film containing acid chloride groups on the surface, dipping the nascent aromatic polyamide composite film containing acid chloride groups on the surface in ethylenediamine, and controlling the temperature at Between 50 and 55°C, after amidation reaction for 2 hours, filter out the membrane, use 10% by mass percentage of sodium carbonate aqueous solution and deionized water, wash ...

Embodiment 2

[0038] Example 2 Preparation of anti-fouling and chlorine-resistant aromatic polyamide composite membrane (2)

[0039] According to the method and operation steps of Example 1, the ethylenediamine in Step 1 of Example 1 is replaced with 1,3,5-triaminobenzene, and the surface containing copper ion and salicylaldehyde Schiff with the number (2) is obtained. Aromatic polyamide composite membrane of base and quaternary ammonium cation (abbreviated as APA / PS-TAB-QA-Cu-(2)).

Embodiment 3

[0040] Example 3 Preparation of anti-fouling and chlorine-resistant aromatic polyamide composite membrane (3)

[0041] According to the method and operation steps of Example 1, the ethylenediamine in Step 1 of Example 1 was replaced with tris(3-aminopropyl)amine, that is to say, the surface containing copper ion, salicylaldehyde Schiff with the number (3) was obtained. Aromatic polyamide composite membrane of base and quaternary ammonium cation (abbreviated as APA / PS-TPA-QA-Cu-(3)).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com