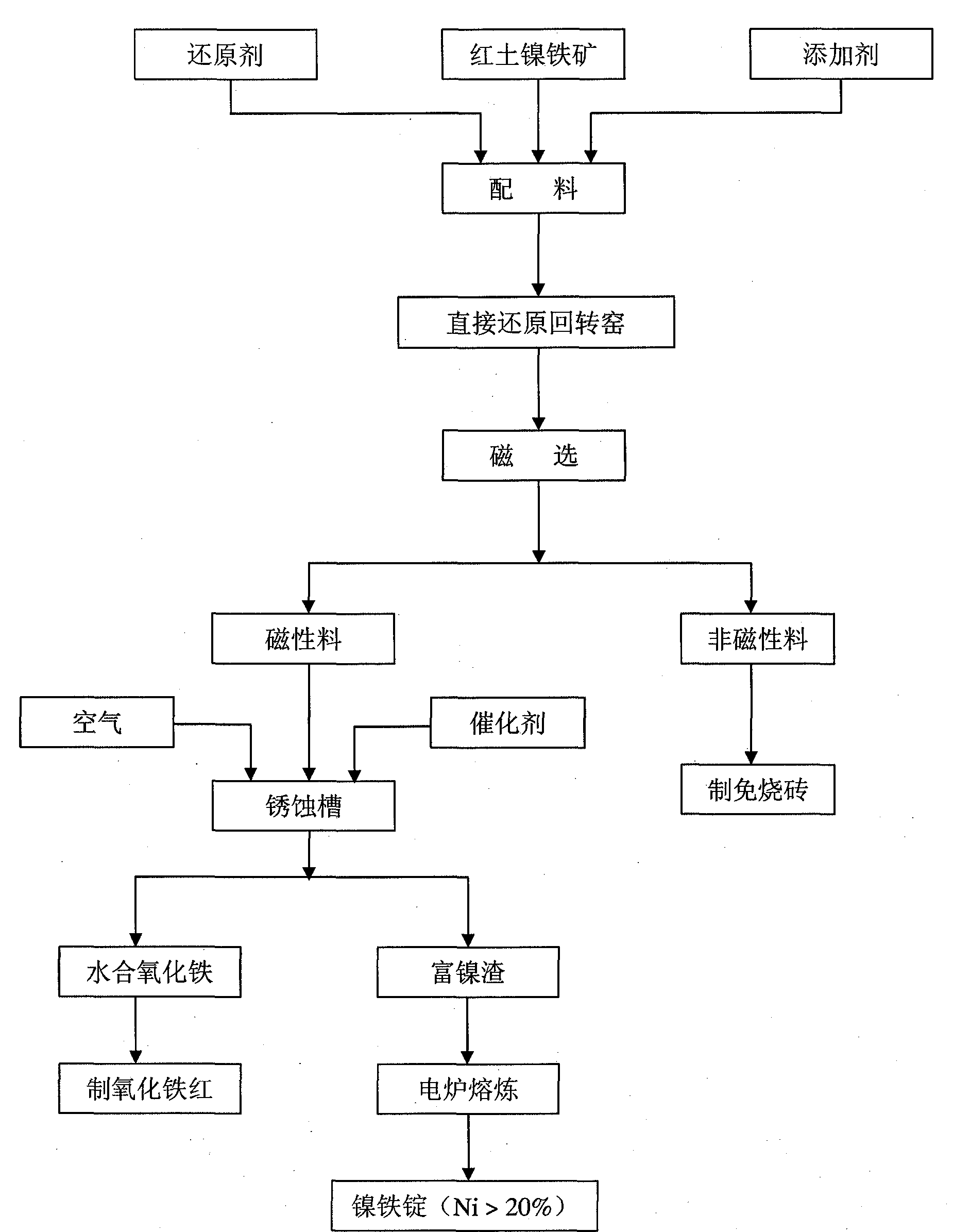

Method for reducing nickel ore by using reducing rotary kiln and producing ferronickel by rusting electric furnace

A production method and technology of rotary kiln, applied in rotary drum furnace, furnace, furnace type and other directions, can solve the problems of high production cost, difficult beneficiation, unavailability, etc., and achieve low cost, significant economic benefits, and good environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A raw material preparation

[0025] Use laterite nickel ore with nickel content ≥0.4%, iron content ≤20%, sulfur content <2% as the base material, select sulfur content ≤0.5%, calorific value ≥7000 kcal, coking index <2, volatile matter ≥34 % of coal is used as reducing coal and fuel injection coal.

[0026] Coal particle size ≤ 15 mm, choose lime with sulfur content < 0.3% as desulfurizer, particle size < 2 mm, the weight ratio of the four components of laterite nickel ore, coal, lime, and additives is nickel ore: 15-80 parts, coal: 15 parts, lime: 1 part, additives: 0.5 parts.

[0027] B, 80 parts of ore in the present embodiment, 15 parts of coal, 1 part of lime, 0.5 part of additive.

[0028] According to the composition ratio, add the ingredients into the kiln from the kiln tail, then spray 15 parts of coal into the kiln head, and add compressed air at the same time, the air volume is 40m 3 / min, the wind pressure is controlled at 60000Pa, and the secondary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com