Linear permanent magnetic rail brake

A rail brake, linear technology, applied in the direction of brakes, railway braking systems, railway car body parts, etc. where the braking element interacts with the track, can solve the problem of increasing the gap between the brake and the track, difficult to control the braking force, and reducing the braking force. Braking effect and other issues to avoid demagnetization, ensure safe operation, and reduce magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

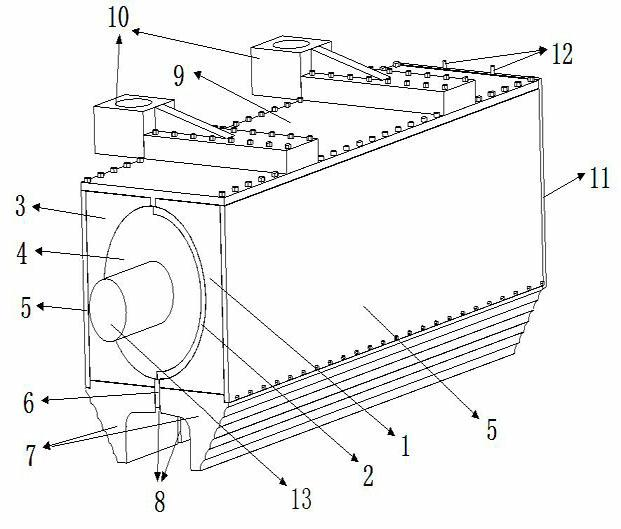

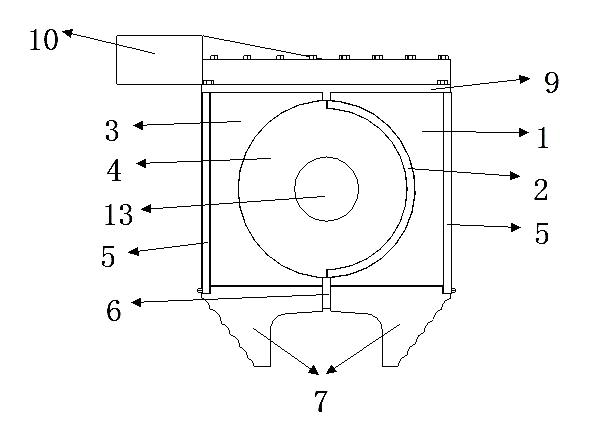

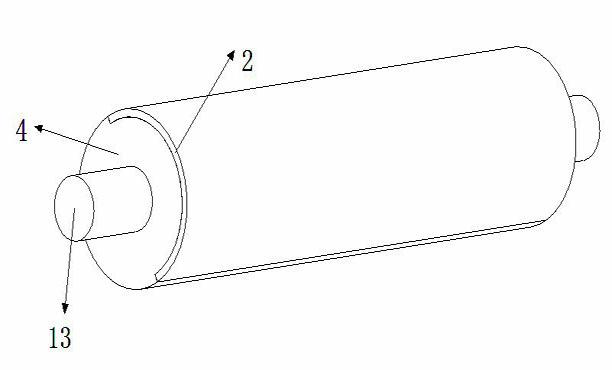

[0017] see Figure 1-3 , the upper part of the present invention is the top cover 9, the two sides of the middle part are the side plates 5, the two ends are the end covers 11, and the lower part is two symmetrical pole shoes 7 which are in symmetrical contact with the track, and the two symmetrical pole shoes 7 The middle of the bottom is fixedly connected to the bottom partition 6, and the bottom partition 6 plays a separating role. A flange 10 is installed on the top cover 9, and the present invention is connected with the train bogie through the flange 10. Install hydraulic cylinder or pneumatic cylinder 12 in end cover 11, install permanent magnet shaft 13 in the middle of two side plates 5, the driving mechanism of hydraulic cylinder or pneumatic cylinder 12 connects permanent magnet shaft 13, drives permanent magnet shaft 13 to rotate, also Axial movement of the permanent magnet shaft 13 can be prevented. The permanent magnet shaft 13 is arranged in the same direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com