Flange drilling center

A technology of flanges and components, which is applied in the field of connecting flange drilling of valve bodies, can solve the problems of long auxiliary time, large investment, low processing efficiency, etc., achieve accurate hole positions, accurate dimensions, and avoid relative offsets Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

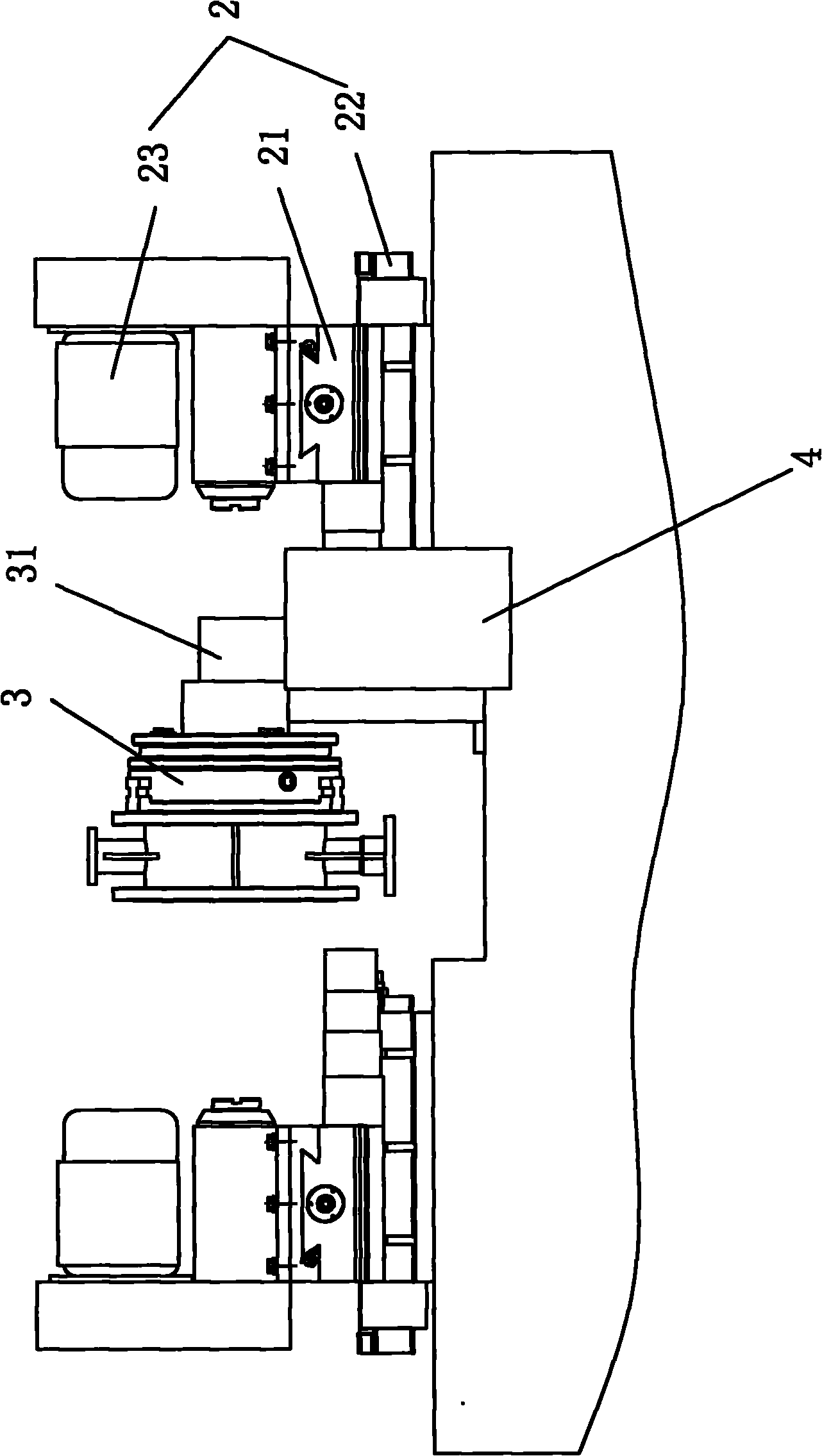

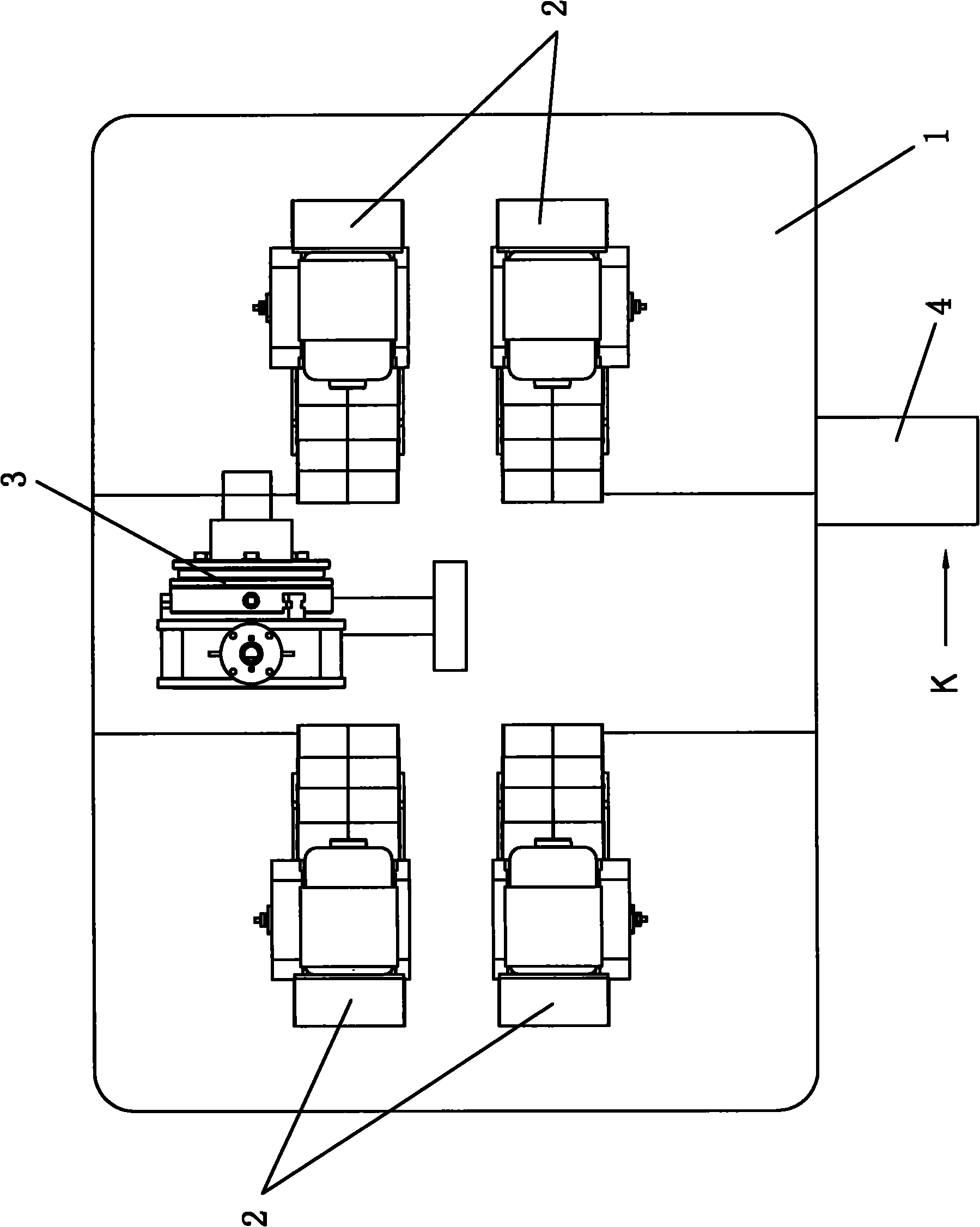

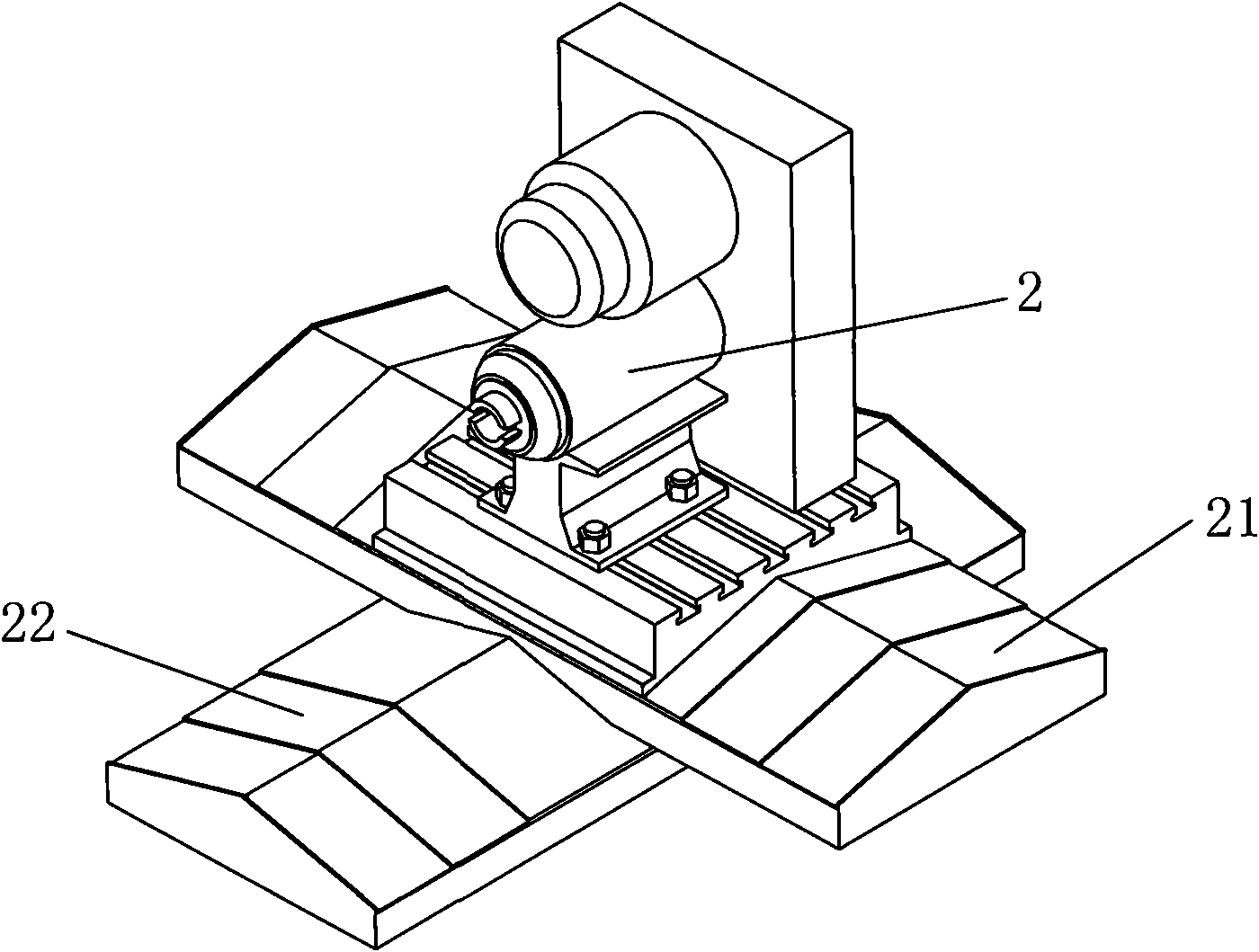

[0035] Such as figure 1 , figure 2 The embodiment of the present invention shown is a flange drilling center, which is characterized in that it includes: a frame 1; a power head assembly 2: set on the frame 1, with a lateral movement device 21 and a longitudinal movement device 22 , driven by the motor 23; clamping and indexing mechanism assembly 3: set on the frame 1, equipped with a moving and rotating device controlled by the hydraulic control system system 31; control panel 4: set on the frame 1, control The power head assembly and the clamping and indexing mechanism assembly move. The drilling center may include four power heads and a set of clamping and indexing mechanisms, and may also include other sets of power heads and clamping and indexing mechanisms. The power head assembly may be provided with drilling and tapping devices.

[0036] Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com