Radial flow reactor with movable supports

A reactor, radial bed technology, applied in the field of radial flow reactor vessels, can solve the problem of radial flow reactors without clear guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

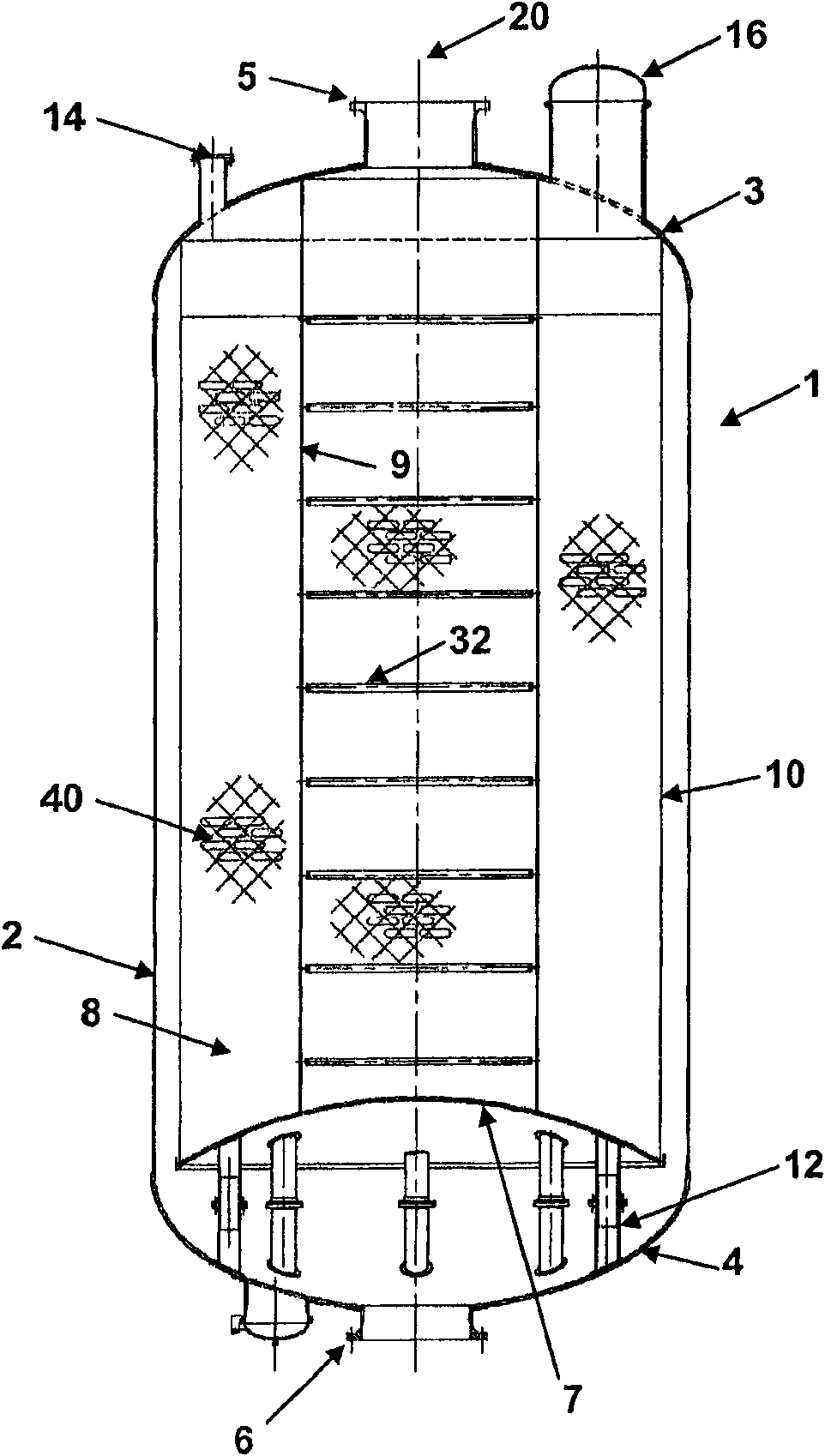

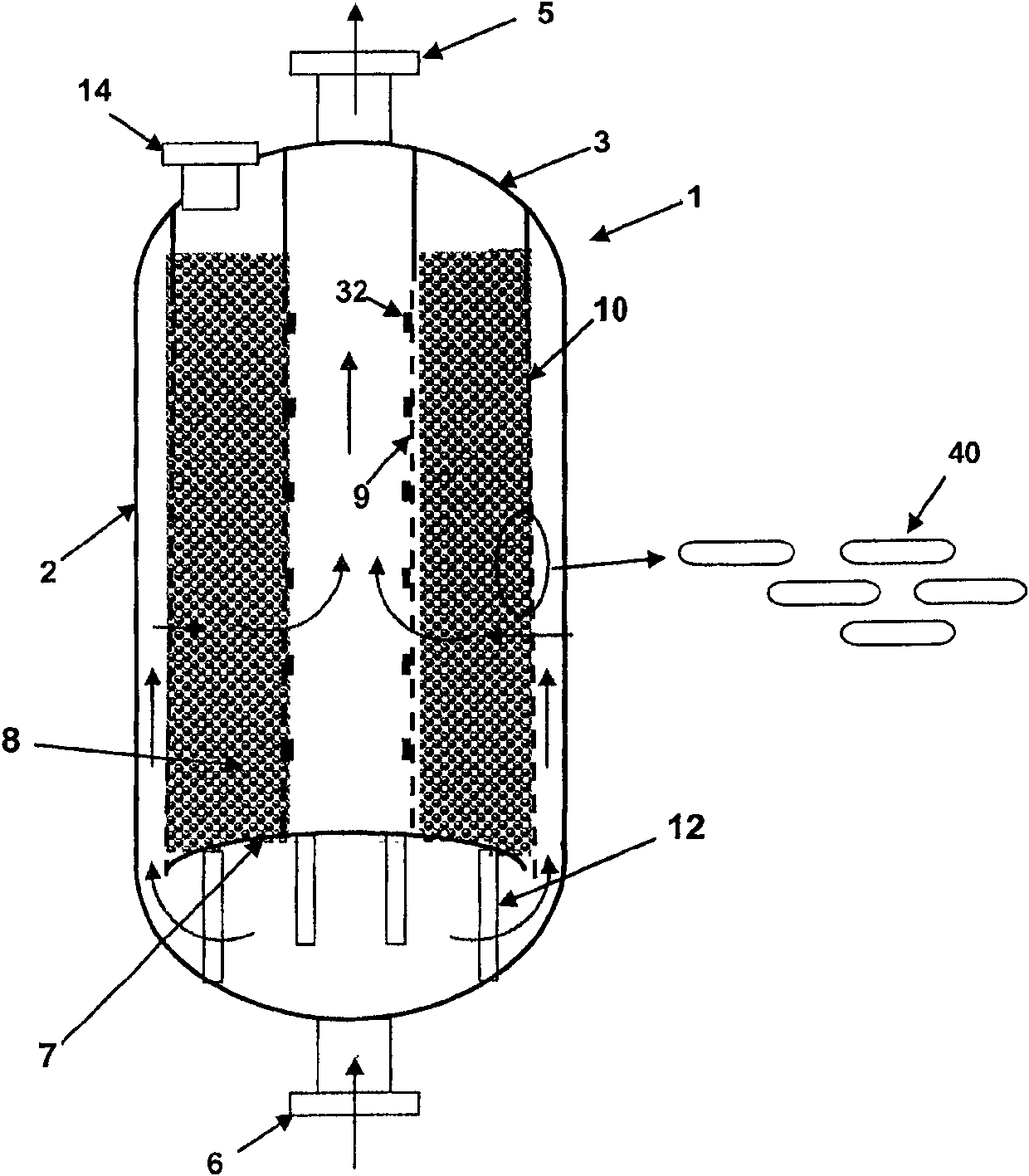

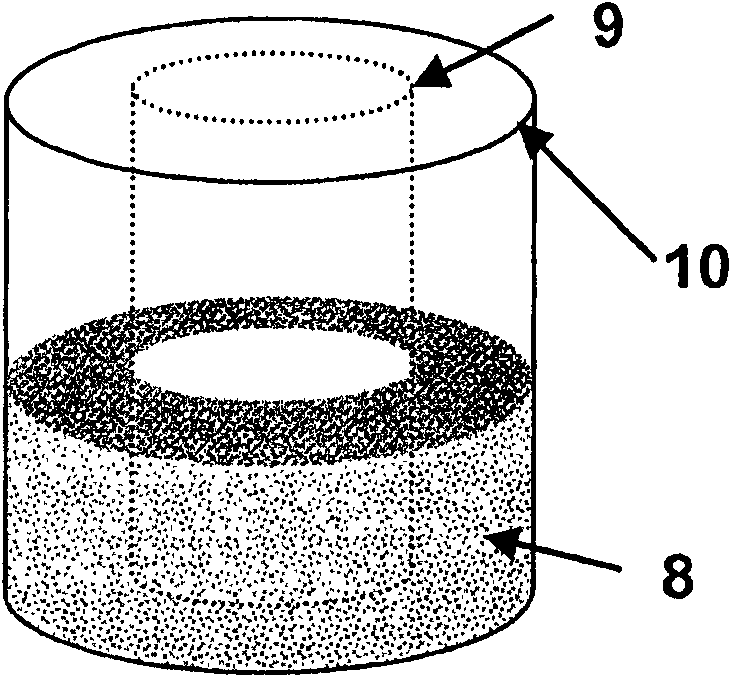

[0038] Figures 1 to 7 The basic structure of one embodiment of the radial flow pressure vessel of the present invention and some of its components are illustrated. figure 1 The cross-sectional views of the present embodiments illustrate essential features of the present invention and the invention, but do not show all fastener arrangements, conduits and equipment details or other aspects of the invention that would be apparent and understood to those skilled in the art. figure 2 is essentially shown as figure 1 A schematic diagram of a vessel of the character shown in , and additionally showing the gas flow path through the vessel. The figure does not represent actual size.

[0039] refer to figure 1 , a substantially cylindrical radial flow reactor vessel (1) on a vertical longitudinal axis (20). The container has an outer shell (2) with upper (3) and lower (4) hemispherical caps generally known in the industry. The lower cover (4) has an inlet (6) for receiving a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com