Combined evaporator

An evaporator and combined technology, applied in the field of combined evaporators, can solve the problem that the falling film evaporator fails to solve the problem of "evaporating the working medium to dryness", and the falling film evaporation technology has not been widely promoted and applied, etc. problems, to achieve the effect of ensuring safety and overcoming more demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

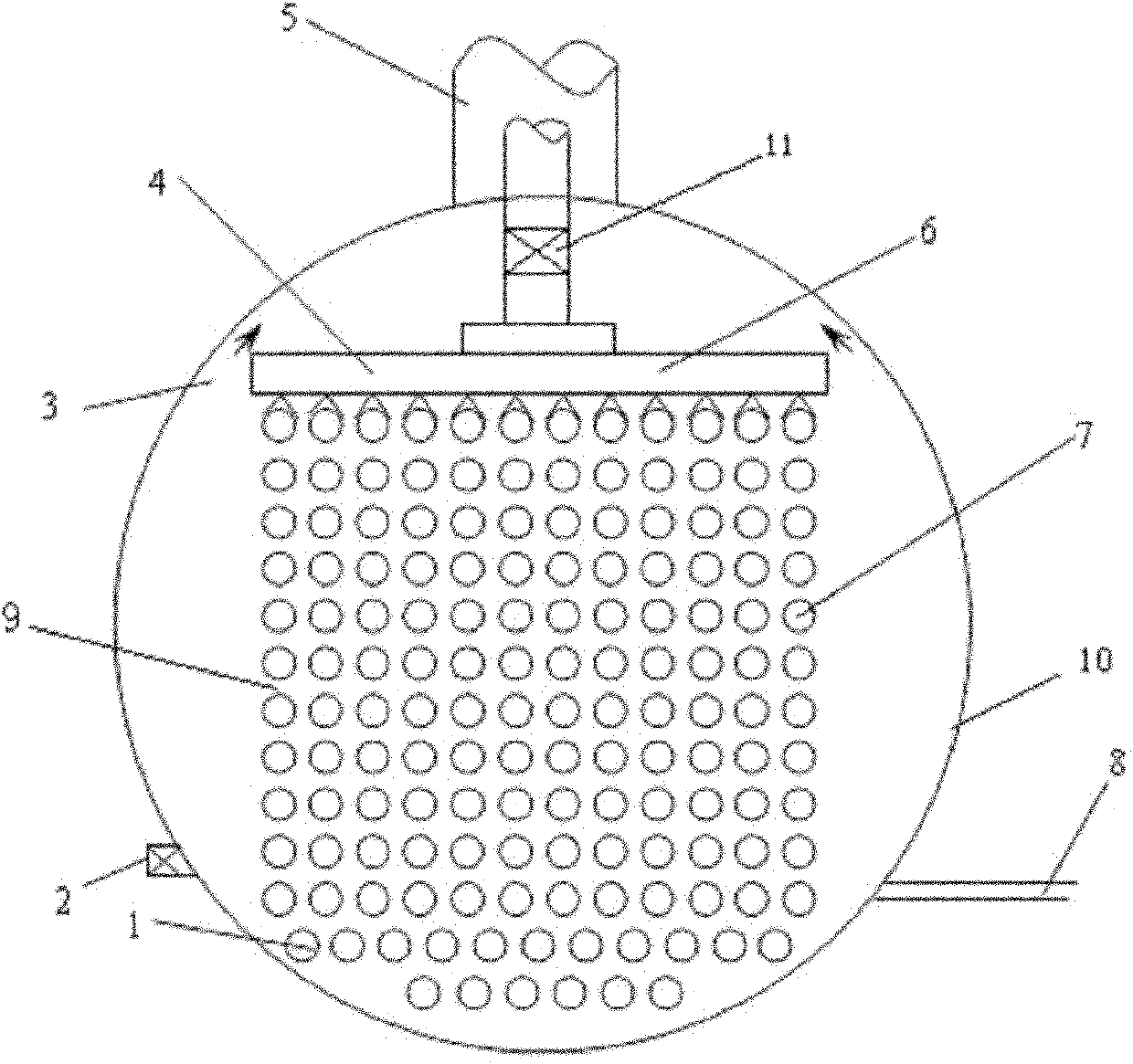

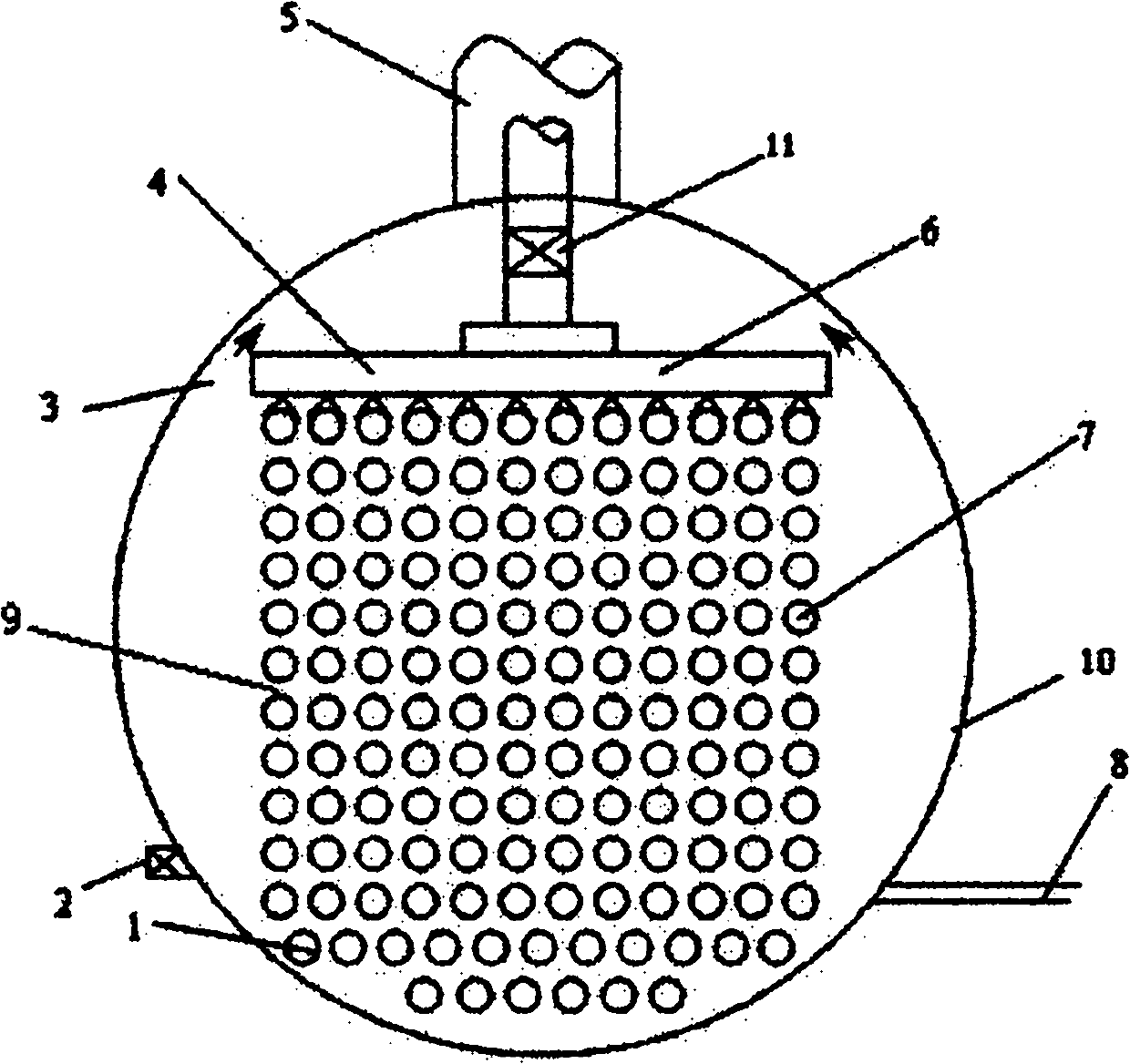

[0019] see figure 1 As shown, a combined evaporator includes an evaporator main body 10, a steam outlet 5 communicating with the evaporator main body 10, and a plurality of heat exchange outlets horizontally arranged in the evaporator main body 10 along the longitudinal direction of the evaporator main body 10. There are airflow channels 9 preset between adjacent heat exchange tubes; the heat exchange tubes include falling film evaporation heat exchange tubes 7 near the top of the evaporator body 10 and flooded heat exchange tubes near the bottom of the evaporator body 10 1. A film distribution device 4 is provided above the falling film evaporation heat exchange tube 7, and the film distribution device 4 has a low boiling point working fluid inlet 6. The width of the film distributor 4 is equal to the row width of the falling film evaporation heat exchange tubes 7 .

[0020] In the evaporator of the present invention, if the liquid level is too high, the heat transfer effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com