Converting device of positive and negative electrodes of rectifier

A technology of positive and negative electrodes and conversion devices, which is applied in the field of conversion devices of positive electrodes and negative electrodes of rectifiers, can solve problems such as poor contact, unreliable working performance, and blown knife, so as to improve electrical conductivity, solve poor contact and contact problems. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

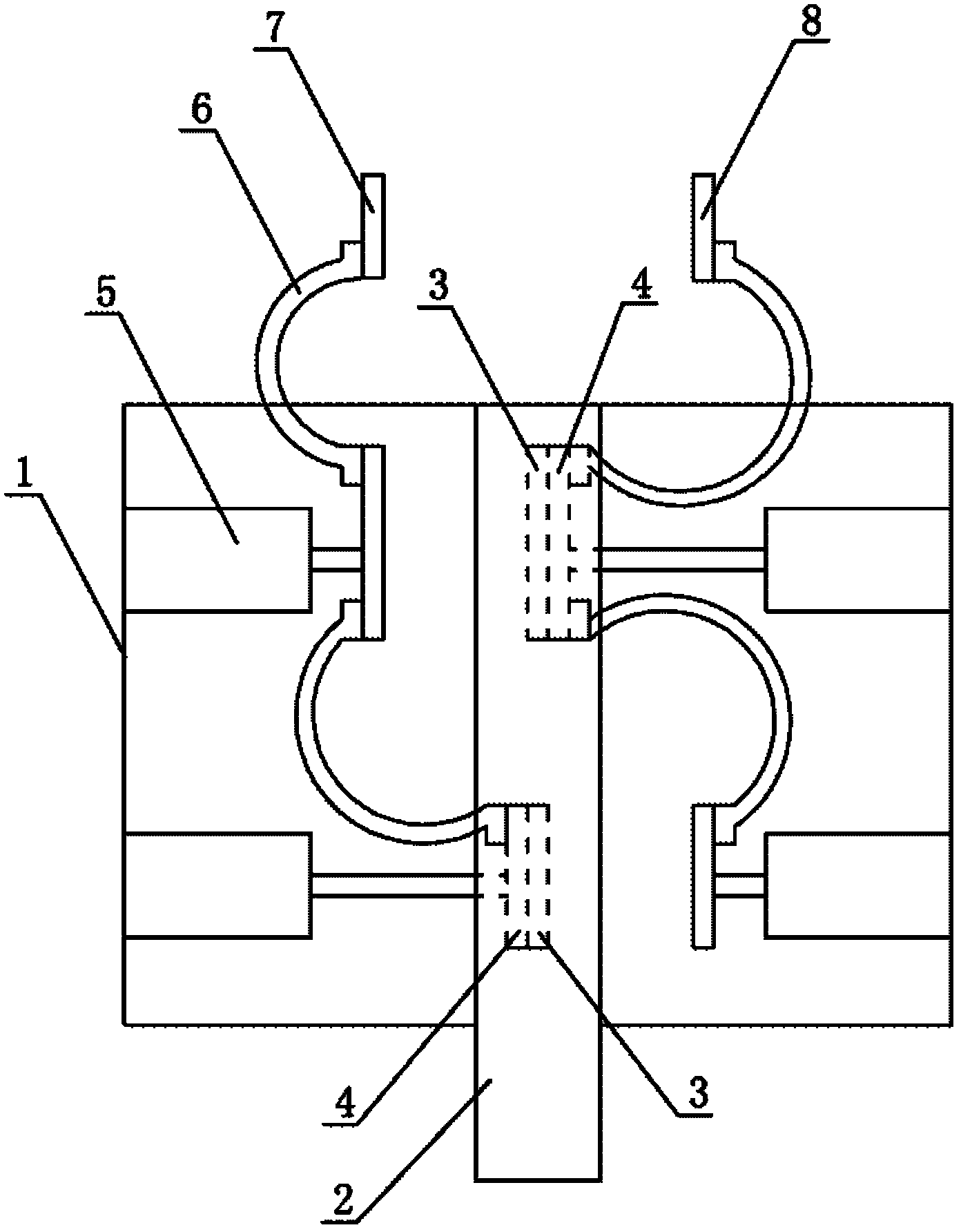

[0011] Such as figure 1 , 2 As shown, a conversion device for positive and negative electrodes of a rectifier is provided with a frame 1, and two electrode plates 2 as output electrodes are installed on the frame 1 with copper bars. The electrode plates 2 are insulated from the frame 1, and are installed parallel to each other with an upper and lower interval. Copper bars are used as two fixed contact plates 3, placed between two electrode plates 2, and a certain distance is maintained, and each is fixedly connected to one of the electrode plates 2. Both sides of the two fixed touch panels 3 are provided with a moving touch panel 4, and each moving touch panel 4 is installed on the frame 1 on both sides through a hydraulic cylinder 5, and the moving touch panel 4 is driven by the hydraulic cylinder 5 to reciprocate in a straight line The movement realizes the contact and separation of the movable contact plate 4 and the fixed contact plate 3, and each movable contact plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com