Permanent magnetic suspension support shafting structure suitable for Antarctic astronomical telescope

A technology of astronomical telescopes and magnetic levitation, which is applied in the direction of telescopes, bearings, shafts and bearings, and can solve the problem of no hydraulic oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

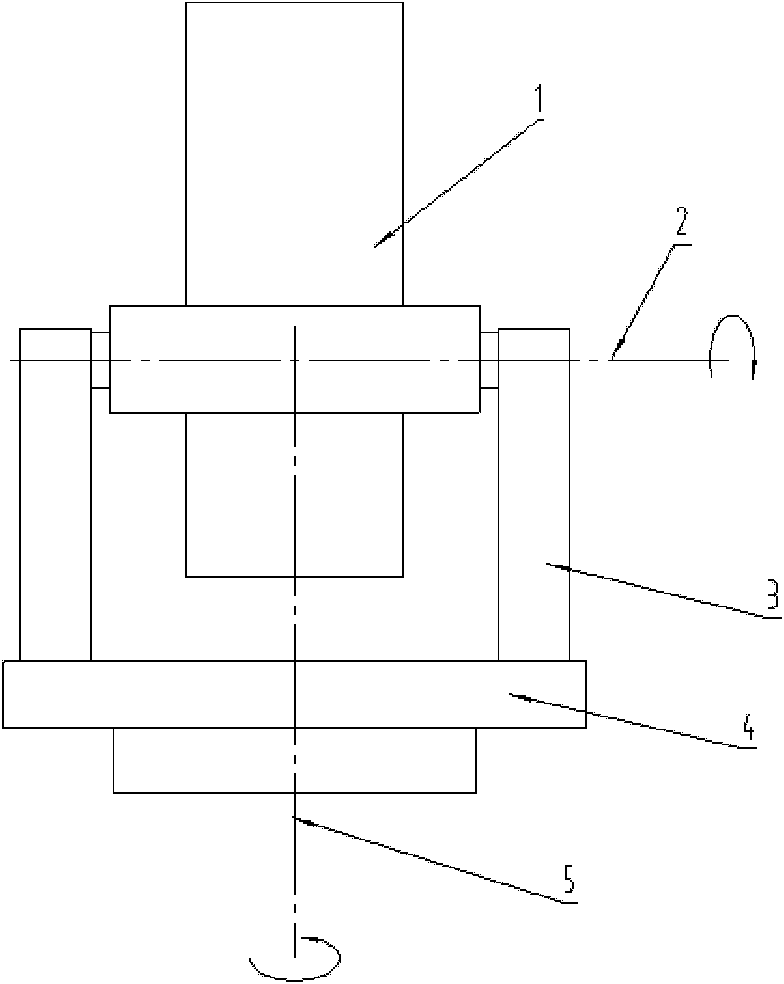

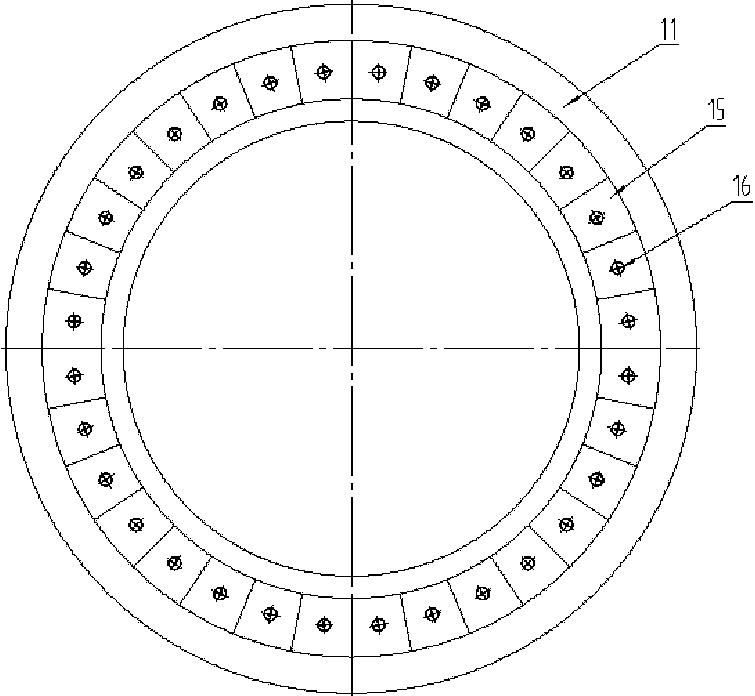

[0031] Embodiment 1, is applicable to the permanent maglev bearing shafting structure of Antarctic astronomical telescope, with reference to figure 2 : the azimuth turntable 4 is fixedly connected to the center positioning shaft 7 through the elastic connecting plate 6, the azimuth turntable 4, the elastic connecting plate 6 and the center positioning shaft 7 are connected as a whole to form the rotor of the azimuth shaft system; the azimuth turntable 4 is passed through the yoke 3 Place the height axis of the telescope and the lens barrel it supports; drive the motor 14 to drive the rotor of the azimuth shaft, thereby driving the entire telescope to achieve azimuth rotation; Between base 11. Non-load-bearing positioning bearings are supported by silicon nitride ceramic bearings with low expansion coefficient, low temperature resistance and self-lubricating. The load-bearing positioning bearing is supported by a permanent magnetic axial bearing, which is composed of a moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com