Locking pin type double-cone synchronizer

A synchronizer and outer cone technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of small diameter of the synchronizer cone surface and achieve the effect of reducing the shifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

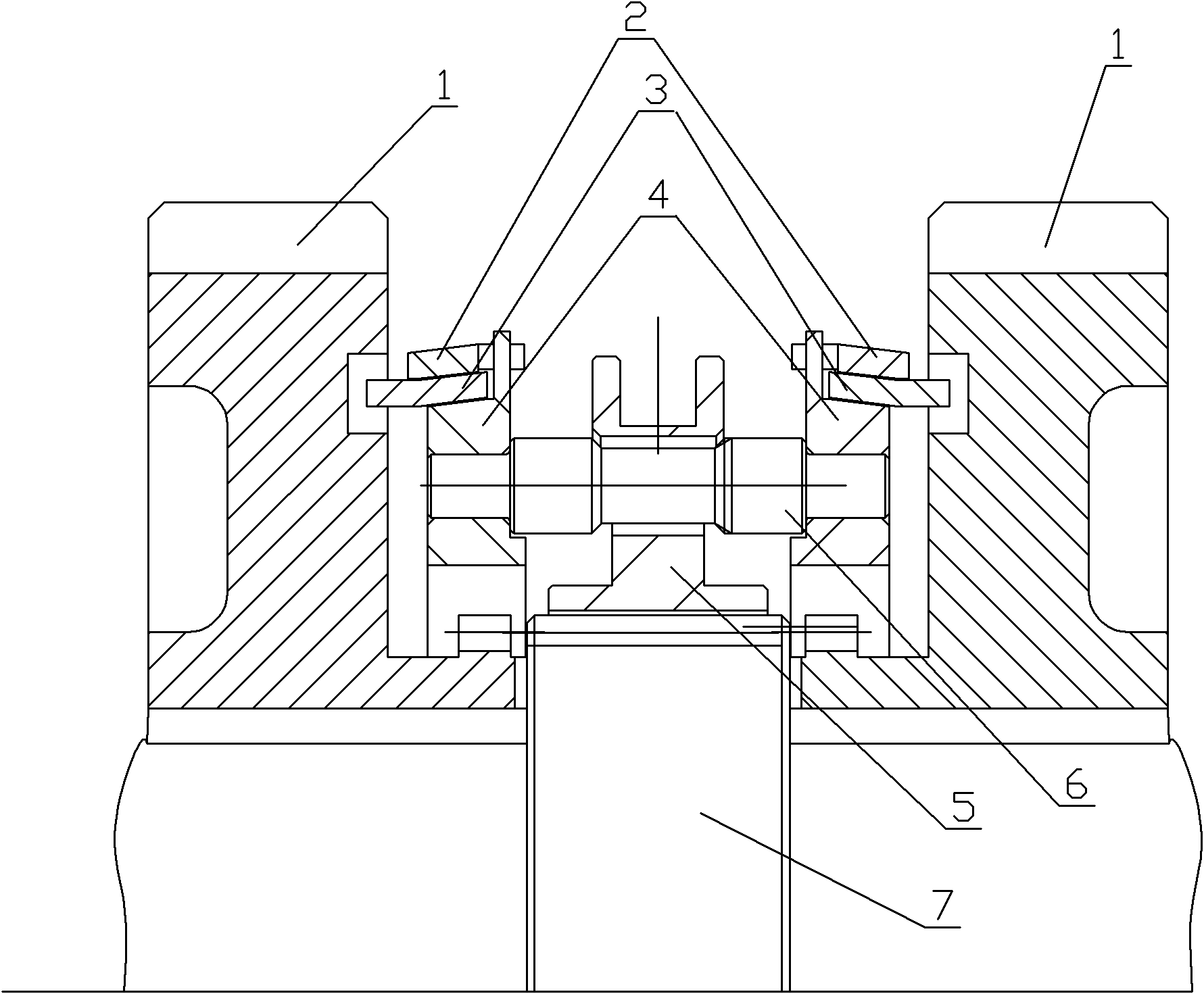

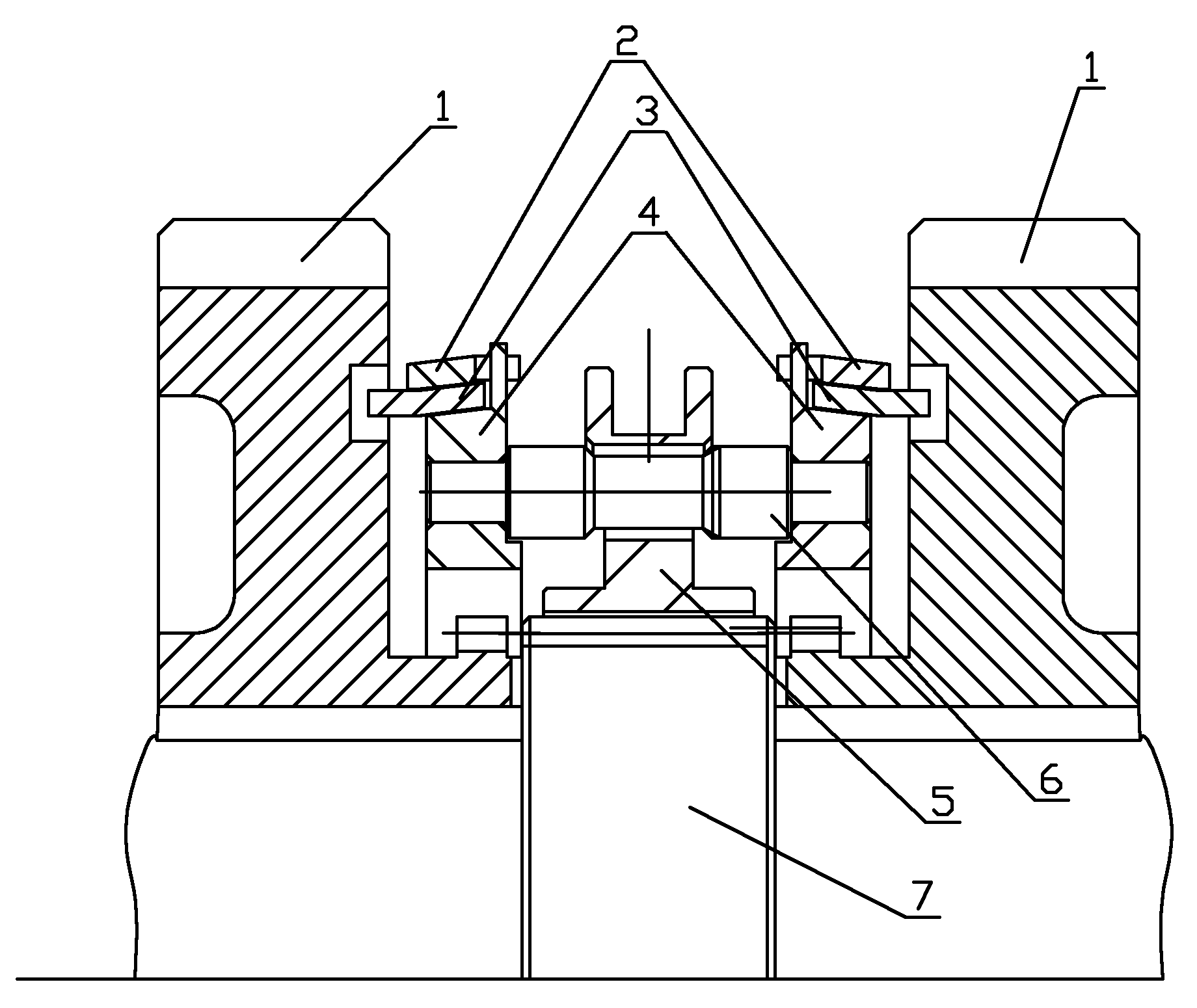

[0008] Such as figure 1 As shown, the double-cone lock-pin synchronizer is mainly composed of an outer cone 2, an intermediate ring 3, an inner cone 4, a gear sleeve 5, a lock pin 6, and a gear 1, wherein the gear sleeve 5 can be freely mounted on the lock pin 6 Sliding, the inner cone 4 is riveted with the lock pin 6, the intermediate ring 3 is floatingly connected with the gear 1 through the protrusion, the outer cone 2 is directly hung on the intermediate ring 3, and is connected with the inner cone 4 through the end claw. In this way, when the transmission is in motion, the tooth sleeve 5 is driven by the tooth seat to rotate with the two shafts, and at the same time the gear sleeve 5 drives the inner cone 4 and the outer cone 2 to rotate together with the two shafts of the transmission, and the intermediate ring 3 rotates with the gear 1. When the transmission changes When the gear is in gear, a relative angular velocity difference is generated between the second shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com