ASA (acrylonitrile-styrene-acrylate) resin with favorable appearance performance and preparation method thereof

A technology of ASA resin and appearance, applied in the field of ASA resin and its preparation, can solve the problems of uneven iridescence and gloss, easy occurrence of white spots, low tinting strength, etc., and achieve simple process flow, excellent appearance performance and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

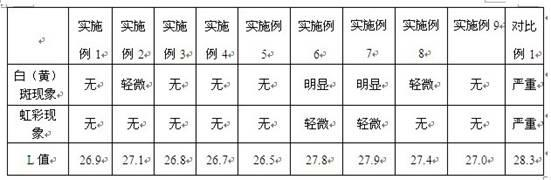

Examples

Embodiment 1

[0042] Scratch-resistant resin with excellent appearance properties is prepared from the following components:

[0043] (1) Preparation of ASA cross-linked modified graft copolymer:

[0044] ASA powder 50 parts

[0045] 40 parts of SAN resin

[0046] 10 parts of the third polymer

[0047] Initiator 0.8 parts

[0048] Antioxidant 0.3 parts

[0049] Lubricant 0.5 parts

[0050] Among them, ASA rubber powder is Kumho, South Korea;

[0051] The SAN resin is Zhenjiang Chimei SAN D168;

[0052] the third polymer is polycarbonate;

[0053] Initiator: BPO;

[0054] The lubricant is PETS;

[0055] The antioxidant is B900;

[0056] (1) ASA rubber powder, SAN resin, third polymer, initiator, antioxidant, and lubricant are fully mixed in a high-speed mixer, and then sent into a twin-screw extruder through a metering device, and the twin-screw extruder is controlled. The temperature of the screw extruder is 180~220°C, the length-to-diameter ratio of the screw is 40, and the scre...

Embodiment 2

[0066] Scratch-resistant resin with excellent appearance properties is prepared from the following components:

[0067] (1) Preparation of ASA cross-linked modified graft copolymer:

[0068] ASA powder 50 parts

[0069] 30 parts of SAN resin

[0070] 20 parts of the third polymer

[0071] Initiator 0.3 part

[0072] Antioxidant 0.3 parts

[0073] Lubricant 0.5 parts

[0074] Among them, ASA rubber powder is Kumho, South Korea;

[0075] The SAN resin is Zhenjiang Chimei SAN D168;

[0076] The third polymer is ethylene-methacrylate copolymer;

[0077] Initiator: BPO;

[0078] The lubricant is PETS;

[0079] The antioxidant is B900;

[0080] (1) ASA rubber powder, SAN resin, third polymer, initiator, antioxidant, and lubricant are fully mixed in a high-speed mixer, and then sent into a twin-screw extruder through a metering device, and the twin-screw extruder is controlled. The temperature of the screw extruder is 180~220°C, the length-to-diameter ratio of the screw is...

Embodiment 3

[0090] Scratch-resistant resin with excellent appearance properties is prepared from the following components:

[0091] (1) Preparation of ASA cross-linked modified graft copolymer:

[0092] ASA rubber powder 60 parts

[0093] 30 parts of SAN resin

[0094] 10 parts of the third polymer

[0095] Initiator 1.0 parts

[0096] Antioxidant 0.3 parts

[0097] Lubricant 0.5 parts

[0098] Among them, ASA rubber powder is Kumho, South Korea;

[0099] The SAN resin is Zhenjiang Chimei SAN D168;

[0100] the third polymer is polysiloxane;

[0101] Initiator: DCP;

[0102] The lubricant is EBS;

[0103] The antioxidant is B900;

[0104] (1) ASA rubber powder, SAN resin, third polymer, initiator, antioxidant, and lubricant are fully mixed in a high-speed mixer, and then sent into a twin-screw extruder through a metering device, and the twin-screw extruder is controlled. The temperature of the screw extruder is 180~220°C, the length-to-diameter ratio of the screw is 40, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com