Wafer grinding device

A grinding device and wafer technology, which is applied in the field of optoelectronic information, can solve the problems of surface roughness, flatness, and wafer thickness tolerances that cannot meet the processing of patterned substrate wafers, high efficiency and low cost, and easy chipping at the edge of the wafer, etc., to achieve grinding The effect of long process time, balanced grinding time, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

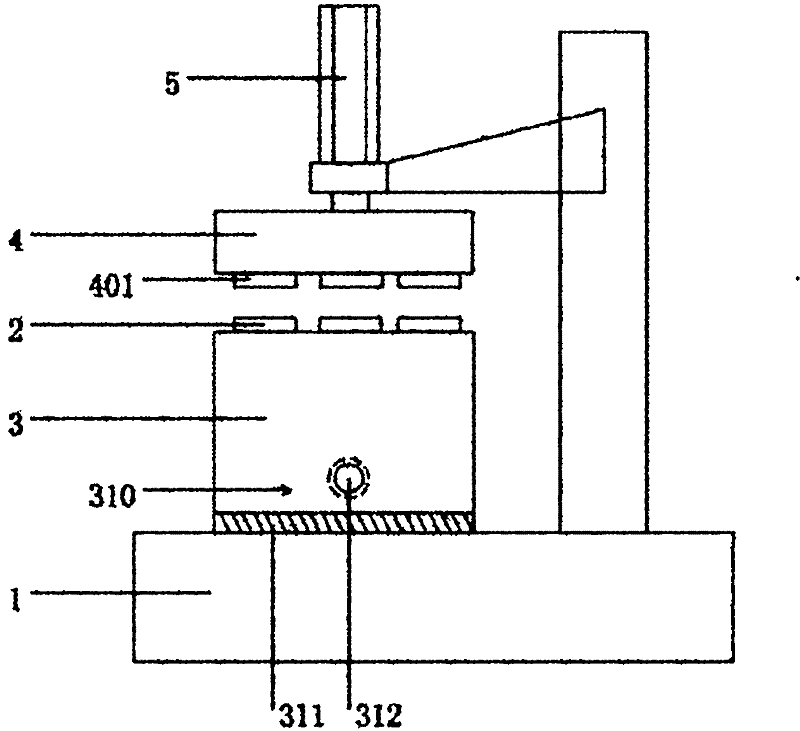

[0022] The present invention will be described below with reference to the drawings.

[0023] See figure 1 , The present invention includes a base 1, which is used to support the components of the grinding device; a wafer carrier 2, which is used to fix and hold the wafer 201; a workbench 3, which is used to support the wafer carrier 2 and is installed on the base 1. The grinding mechanism 4, which is used to grind the wafer 201, is located above the table 3; the pressure mechanism 5, which is used to apply pressure to the grinding head 401, is located above the grinding mechanism 4, and the pressure mechanism 5 adopts Air pressure device.

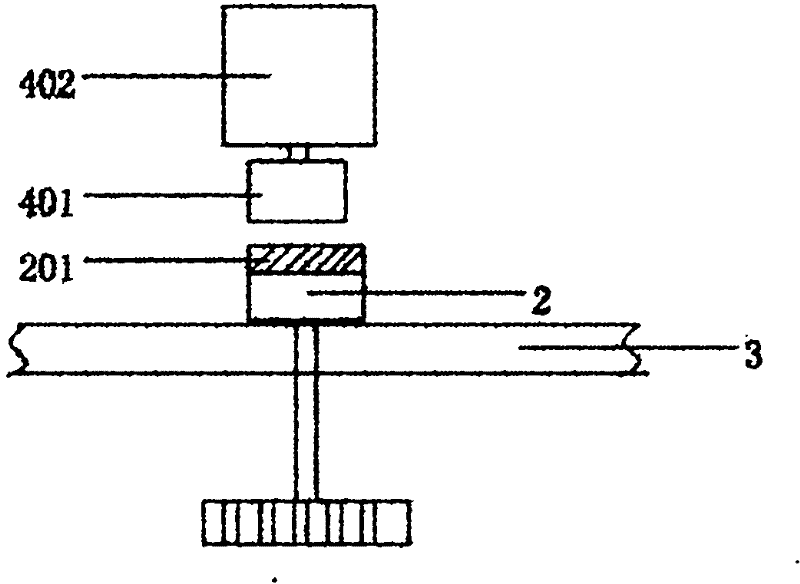

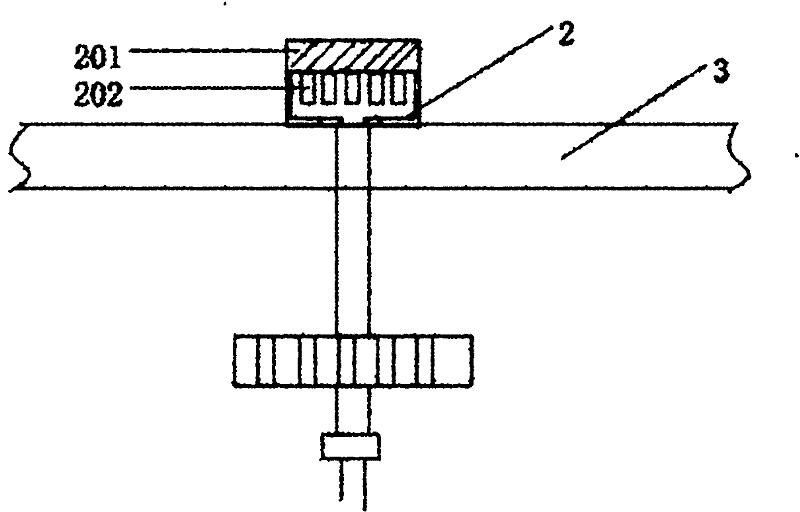

[0024] See figure 2 with Figure 5 The grinding mechanism 4 includes a grinding head 401, a driving motor 402 arranged above the grinding head 401 and used for driving the grinding head 401 to generate a rotational movement, and a coupling member 403 for fixing the grinding head 401. The connecting component 403 includes a movable support 404...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com