High-temperature atmosphere rotary kiln with lining pipe of hexagonal structure

A hexagonal, lined pipe technology, applied in the field of material conveying heating, can solve the problems of low production line production efficiency, long heating time, and delay in production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

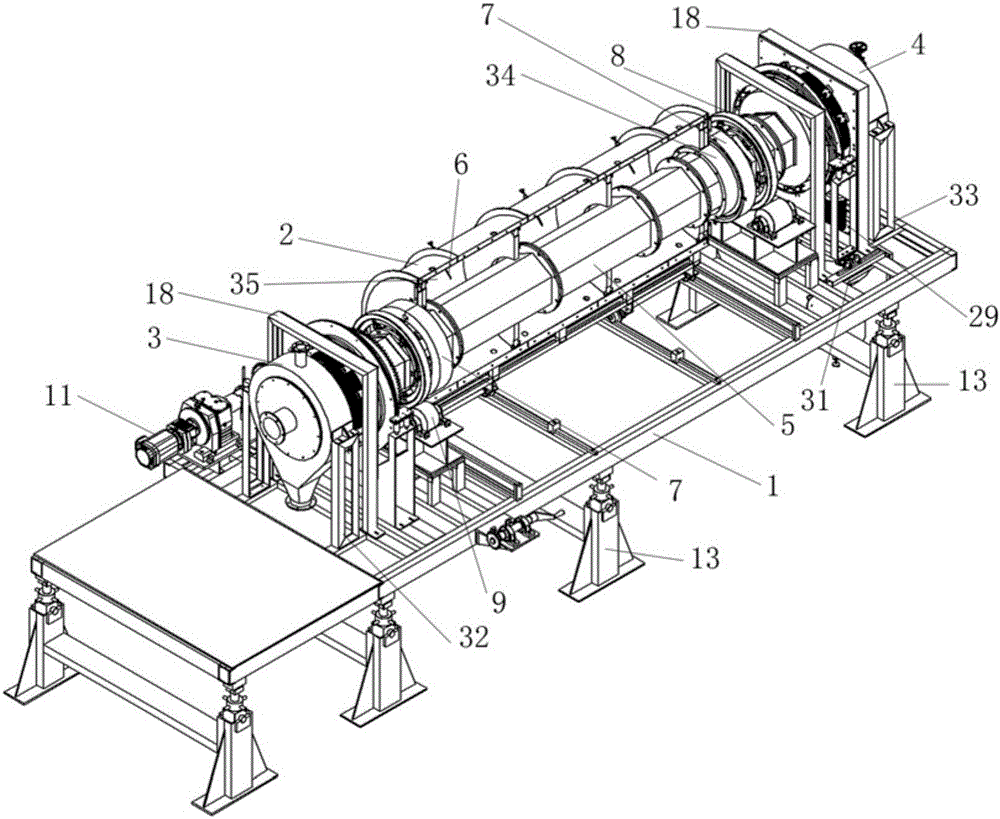

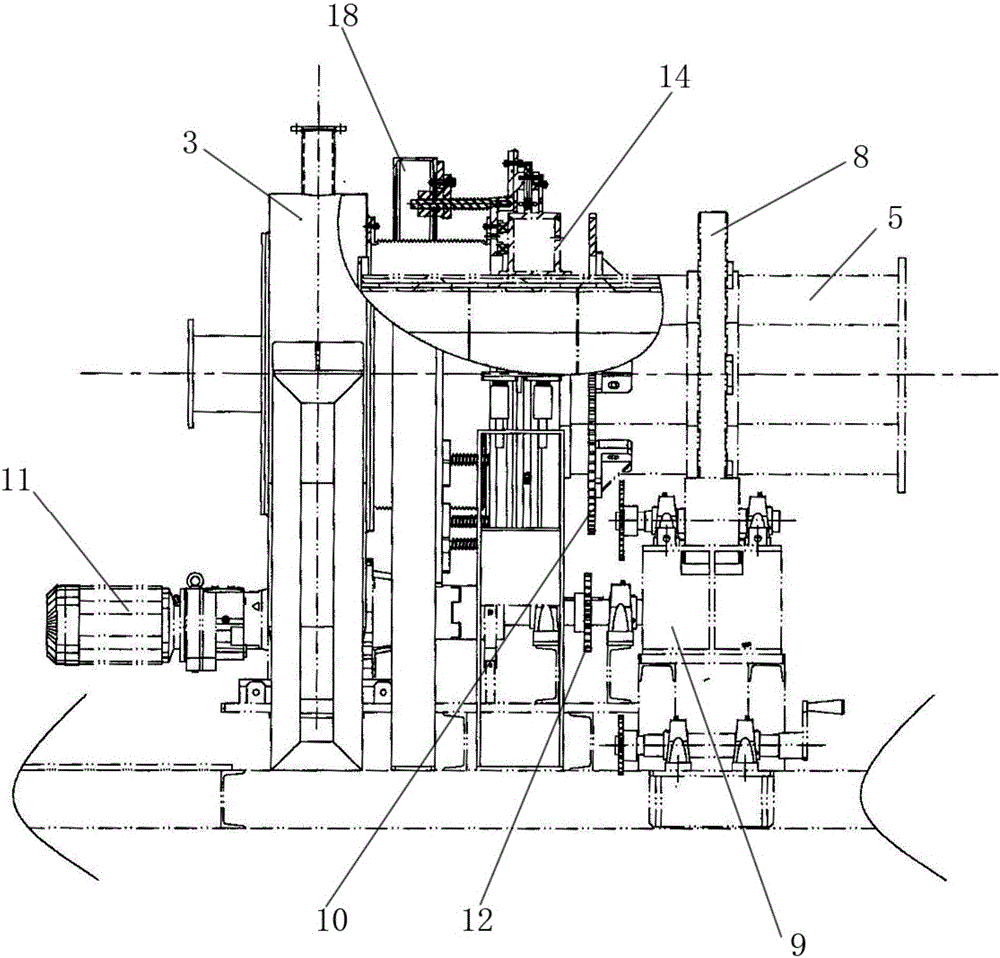

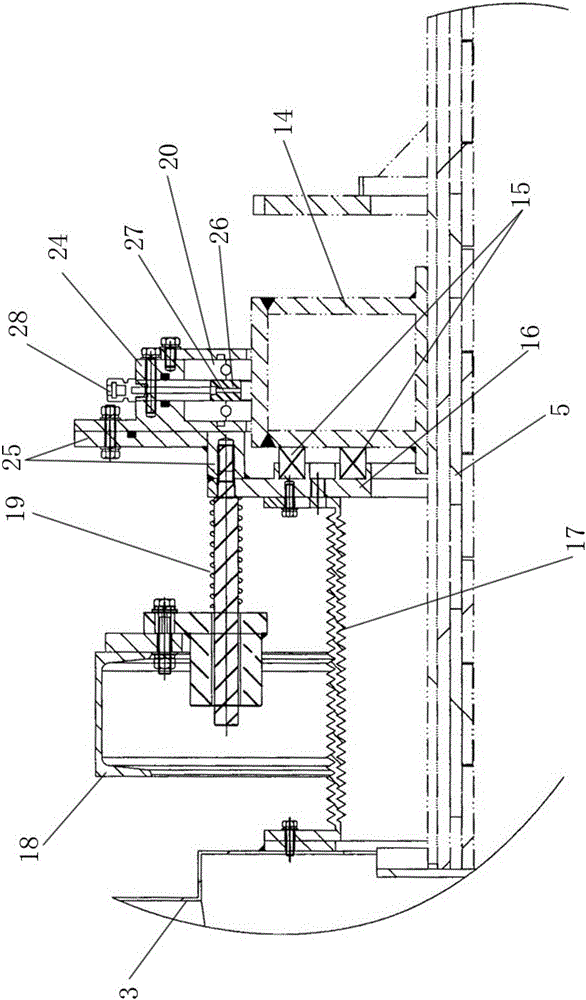

[0026] A high-temperature atmosphere rotary furnace with a hexagonal inner liner, see Figure 1 to Figure 8 : It includes a bottom plate 1, a heating shell 2 is arranged on the bottom plate 1, and the two ends of the heating shell 2 are respectively provided with a hopper 3 and a hopper 4, and the inside of the heating shell 2 is provided with a furnace tube 5, and the heating shell 2 Multiple sets of thermocouples 6 are arranged in the internal compartment formed by the furnace tube 5. The cross-section of the lining tube of the furnace tube 5 is a hexagonal structure, and the inlet and outlet ends of the furnace tube 5 are respectively exposed to the heating shell. Two ends of 2, the connection positions of the inlet end and the outlet end of the furnace tube 5 and the two ends of the heating shell 2 are respectively provided with a circular ring 34, and the outer cover of the circular ring 34 is equipped with a rotating bearing structure 7, and the exposed The inlet and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com