Cutting, splitting and breaking transformation construction method for existing overall ballast bed of subway

A technology of integral ballast bed and construction method, which is applied to roads, tracks, laying tracks, etc., can solve the problems of large amount of construction waste, poor economy, and low work efficiency, and achieve the effects of broad promotion prospects, low environmental pollution, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

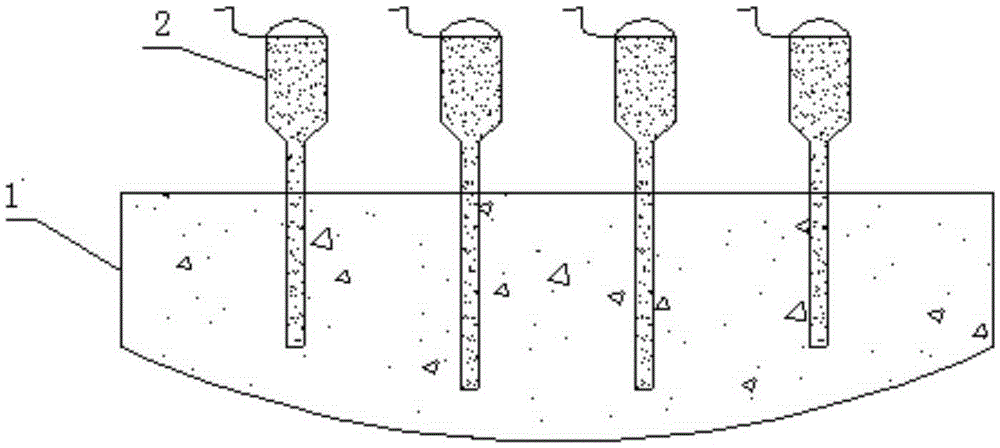

[0009] Referring to the accompanying drawings, it is a construction method of cutting, splitting, breaking, and rebuilding the existing integral track bed of the subway. First, use a wall saw to vertically cut the track bed on the concrete track bed slab 1 along the line lengthwise at an interval not greater than 3.6 cm. The cutting depth is from the concrete surface to the cutting of the steel bar. , but the segment must not be damaged, and then use a core drilling machine to drill holes along the cutting seam. The number of holes is 2 to 6. The splitting rod 2 is inserted into the borehole to adjust the splitting direction, pressurized and expanded until the slab is separated from the pipe wall, and finally the existing slab that has been demolished is lifted by the cantilever crane in the subway tunnel and a new floating slab is constructed to complete the existing whole Track bed renovation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com