Solid-fluid coupling pressure controlled hydrocarbon generation and expulsion simulating experimental device

A simulation experiment device, a technology for generating and expelling hydrocarbons, which is applied in the methods of chemically changing substances by using atmospheric pressure, pressure vessels used in chemical processes, chemical instruments and methods, etc. It can solve problems such as difficulty in effectively simulating effects, To achieve the effect of improving control methods and good experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

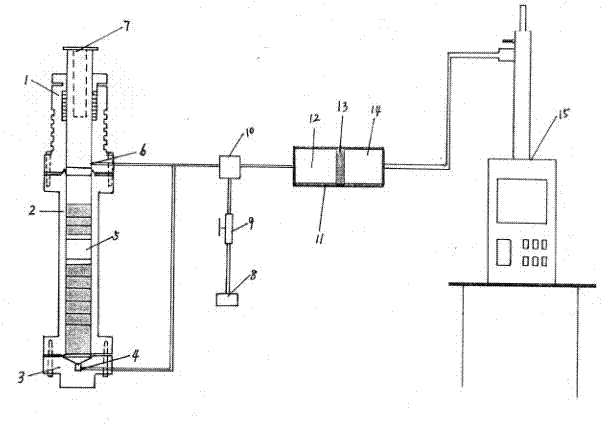

[0012] The autoclave autoclave of the present invention is composed of an autoclave main body 2, an autoclave top cover 1 and an autoclave base 3, and the autoclave main body 2 provided with a sample chamber 5 is connected with an autoclave top cover 1 and an autoclave base 3 respectively on the upper and lower sides , the middle part of the autoclave has a vertical pressure column 7 in the axial direction, and the high-pressure pipeline between the autoclave and the high-pressure buffer 11 with a piston 13 is connected with a three-way valve 10, and the high-pressure buffer 11 is connected to the fluid pressure control pump 15. Connection, the connecting pipeline between the three-way valve 10 and the gas extraction device 8 is connected with a two-way valve 9 with a switch, a stainless steel piston 13 is inside the high-pressure buffer 11, and distilled water 14 for controlling pressure and analog The formation fluid 12 communicates with the upper connection hole 6 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com